Steaming-resisting and solvent-free adhesive and preparation method thereof

A solvent-free, adhesive technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, adhesives, etc., can solve the problems of low initial adhesion and small molecular weight of the adhesive strength, and achieve improved initial adhesion , low viscosity, excellent coating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of a retort-resistant solvent-free adhesive is as follows:

[0034] (1) Weigh raw materials:

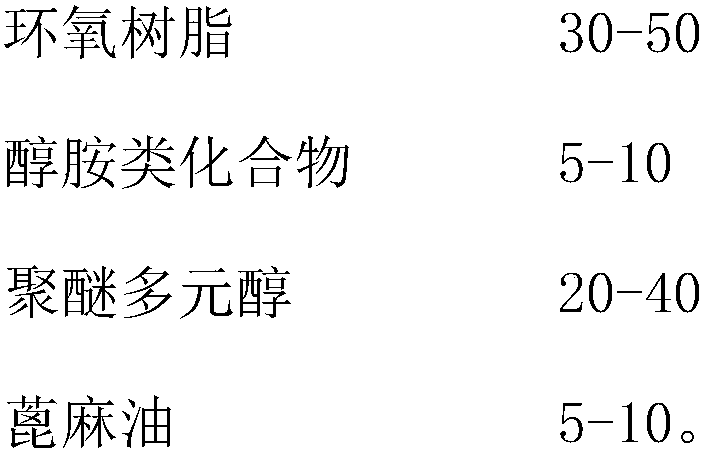

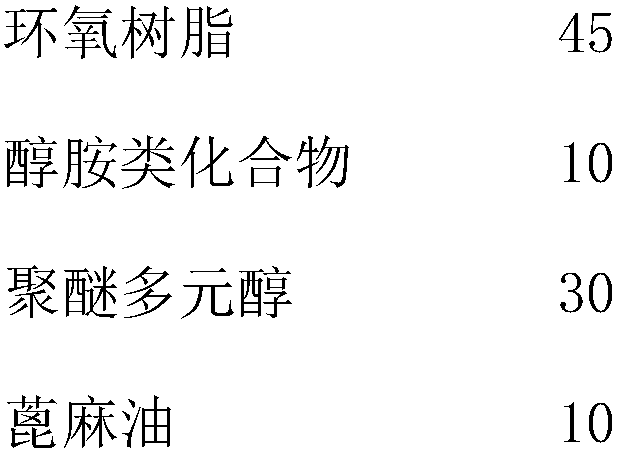

[0035] The isocyanate component comprises the following raw materials in parts by weight:

[0036] Isocyanate 120

[0037] Polyether polyol 30

[0038] castor oil 10

[0039] Curing agent component comprises the raw material of following weight portion:

[0040]

[0041] Wherein, the mass ratio of polyether diol to polyether triol in polyether polyol is 2:1.

[0042] (2) Preparation of isocyanate component:

[0043] Remove water from polyether polyol and castor oil at 0.09MPa, 110°C for 1 hour, cool down to 40°C, protect with nitrogen, add isocyanate and react at 75°C for 3 hours to obtain isocyanate component.

[0044] (3) Preparation of curing agent component:

[0045] Remove water from polyether polyols, castor oil, and alcohol amine compounds at 0.09MPa and 110°C for 1 hour, cool down to 75°C, protect with nitrogen, add epoxy resin, react for...

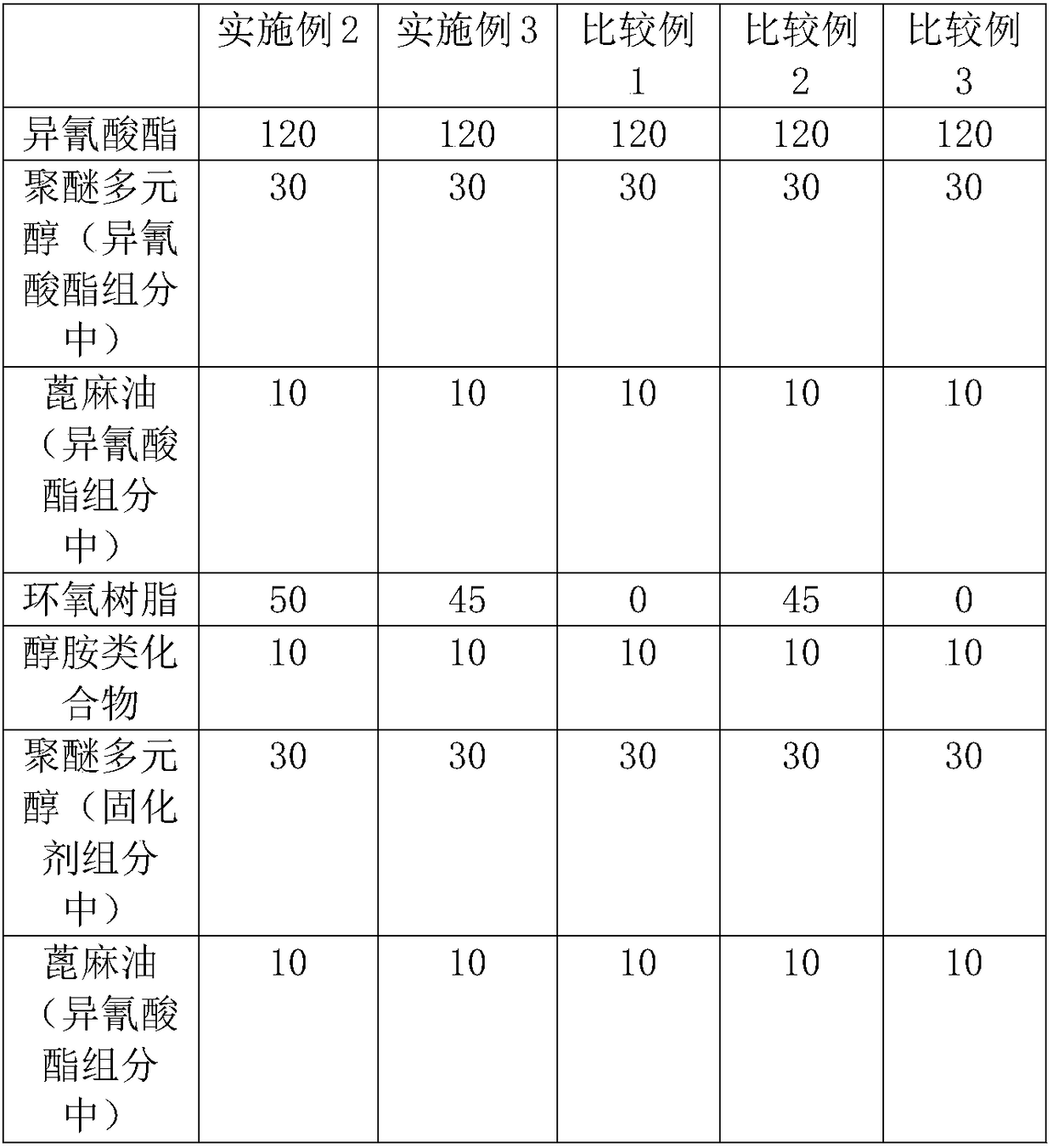

Embodiment 2-5

[0047] The preparation method process is the same as that of Example 1, and the consumption of raw materials is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com