Wall surface paint brushing device with automatic feeding function

An automatic feeding and functional technology, applied in the direction of construction, building construction, etc., can solve problems such as safety hazards, paint splashes, limited paint, etc., and achieve the effects of improving work efficiency, painting evenly, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

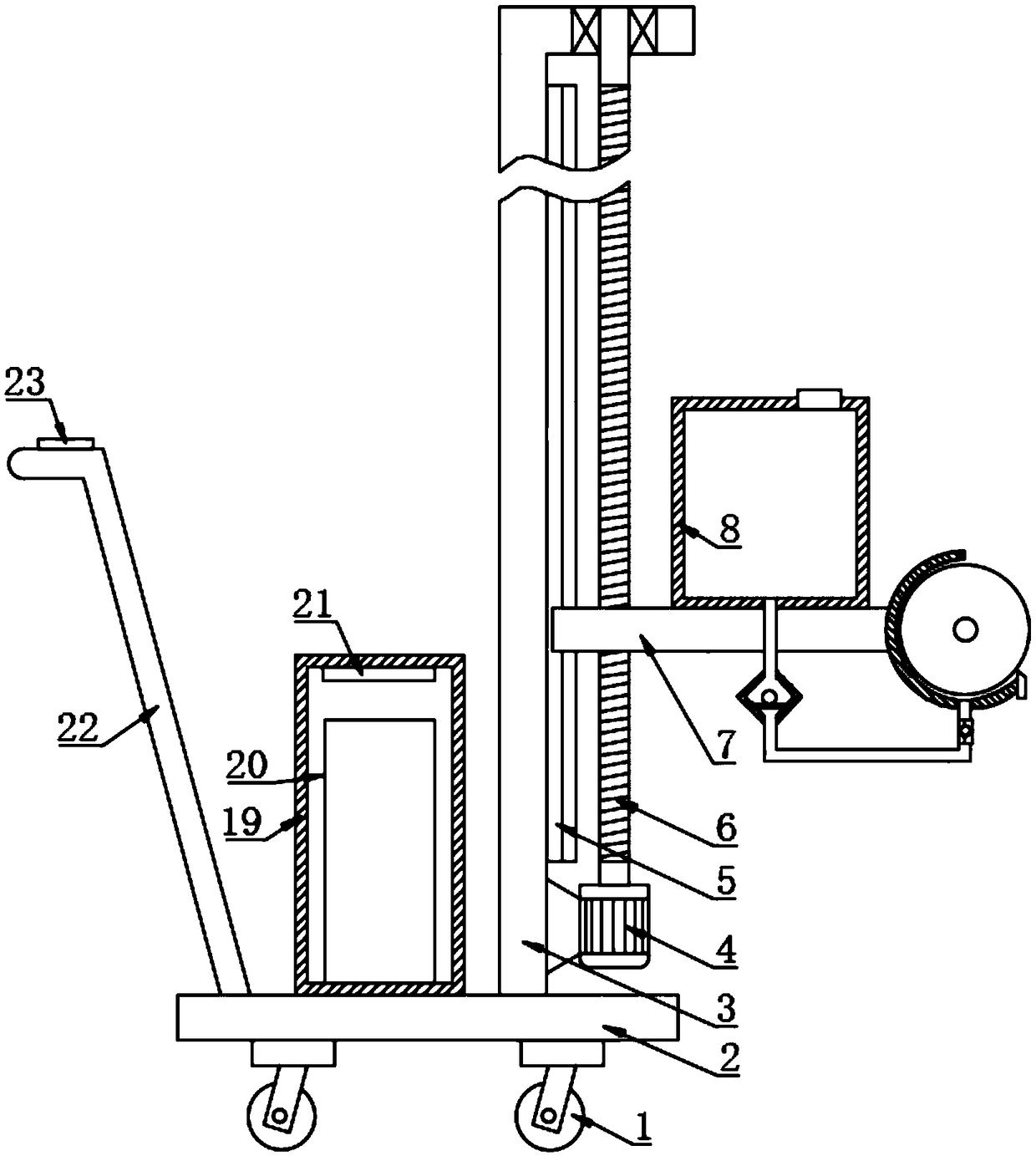

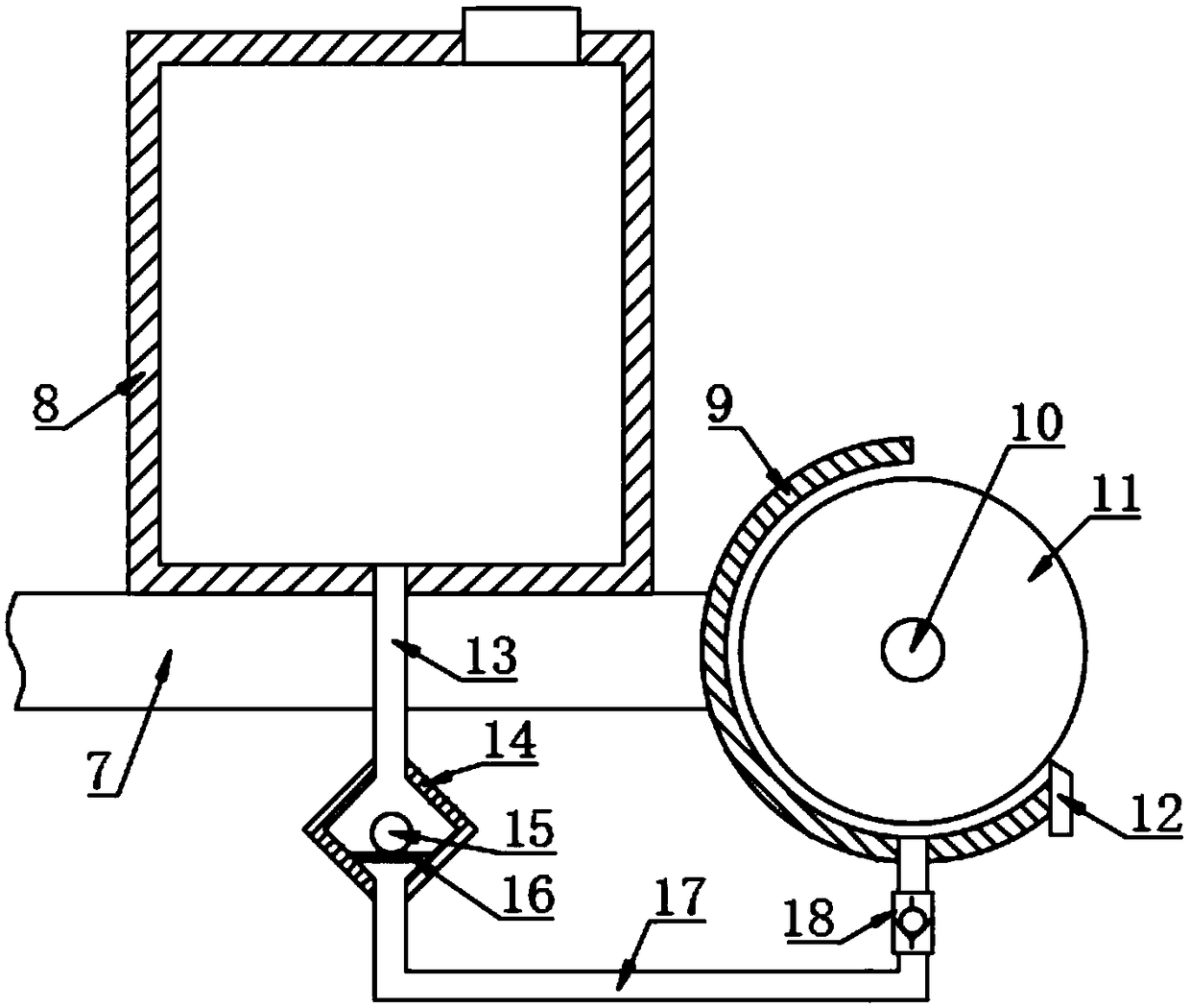

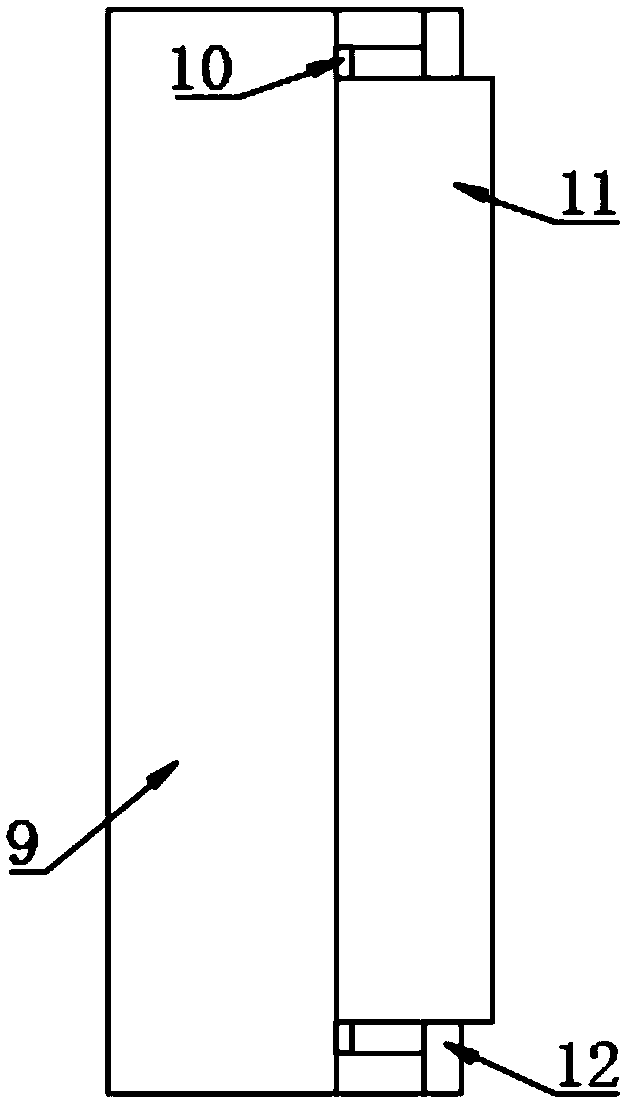

[0026] see Figure 1~3 , in an embodiment of the present invention, a wall painting device with automatic feeding function, including a base 1, a universal wheel 1 is installed on the bottom of the base 1, and a push rod 22 is fixedly connected to the upper right corner of the universal wheel 1 , to facilitate the mobile device; the right side of the top of the base 2 is fixedly connected with a vertical support plate 3, the support plate 3 is in the shape of “Г”, the right side wall of the support plate 3 is fixedly provided with a slide rail 5, and the slide rail 5 The right side is slidingly connected with a lifting plate 7, and the bottom of the right side wall of the support plate 3 is also fixedly provided with a first reduction motor 4, and the motor shaft at the top of the first reduction motor 4 is connected with a screw 6, and the screw rod 6 passes through the lifting plate 7 And it is threadedly connected with the lifting plate 7; the top of the screw rod 6 is rota...

Embodiment 2

[0030] see Figure 2-5, on the basis of embodiment 1, the top of the base 2 is also provided with a stirring box 24, the top of the stirring box 24 is provided with a feeding port, the center of the top of the stirring box 24 is fixedly provided with a second reduction motor 25, and the second reduction The motor shaft at the bottom end of the motor 25 passes through the top wall of the stirring box 24 and is fixedly connected with a rotating rod 26, and the rotating rod 26 is fixedly equipped with a stirring blade 27, and the paint is stirred by the stirring blade 27, so that different paints can be mixed and allocated; Stirring blades 27 are arranged in a staggered manner, the stirring range is wide, and the stirring effect is good; the second reduction motor 25 is connected with the control circuit board 21 through wires, and the control button 23 also includes a start-stop switch of the second reduction motor 25, which is convenient for controlling the second reduction moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com