Heating cable with temperature and breaking point sensing functions

A technology of sensing function and heating cable, applied in the application of thermometer, shape of thermometer, heating element, etc., can solve the problems of low accuracy of optical fiber acquisition temperature, high cost of additional construction, high cost of temperature sensing, etc., and achieve low maintenance cost. , The effect of low construction cost and accurate temperature data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

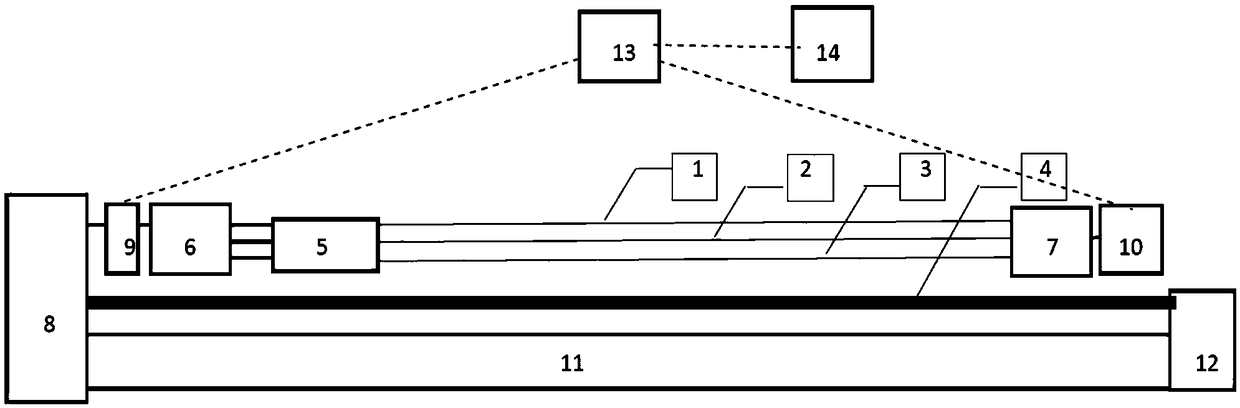

[0041] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0042] When producing cables, sensor modules 5 are arranged equidistantly on the main cable 4 in advance. The sensor modules 5 are driven by the positive power line 1 and the negative power line 3 and communicate with the communication master controller through the data bus 2 . The main communication controller 6 is connected with the wireless transceiver 9 of the main controller, and communicates with the cloud server 13 through the wireless transceiver 9; Communicate with cloud server 13. The cloud server 13 collects and stores the data collected by the sensor modules 5 distributed on the cables, and combines the data of the heat tracing control system 8 for calculation and analysis. Through the user browser 14, the user can view the operating status, fault prompt and breakpoint position display of the cable system. Among them, the positive pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com