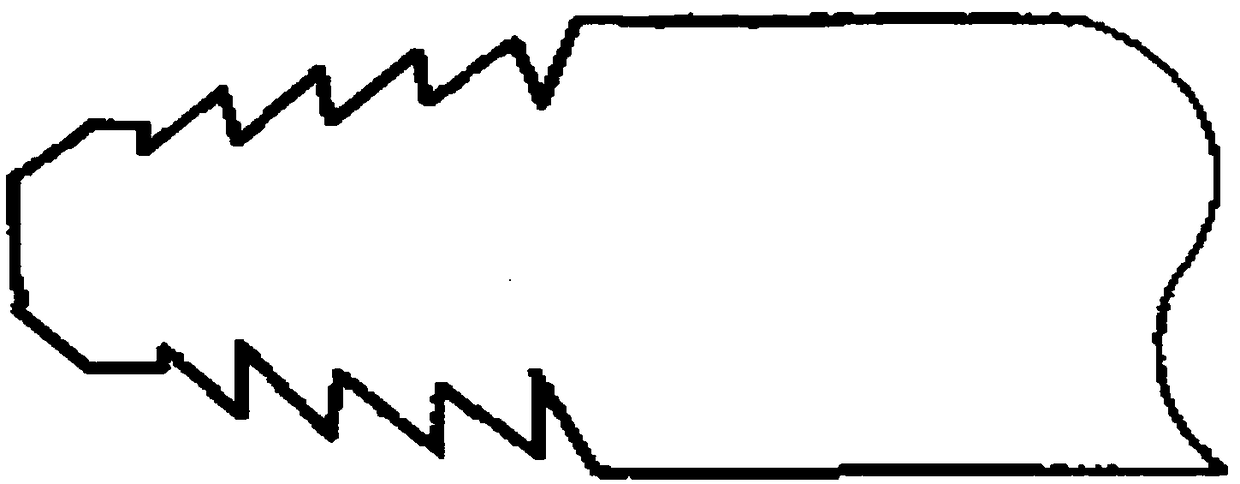

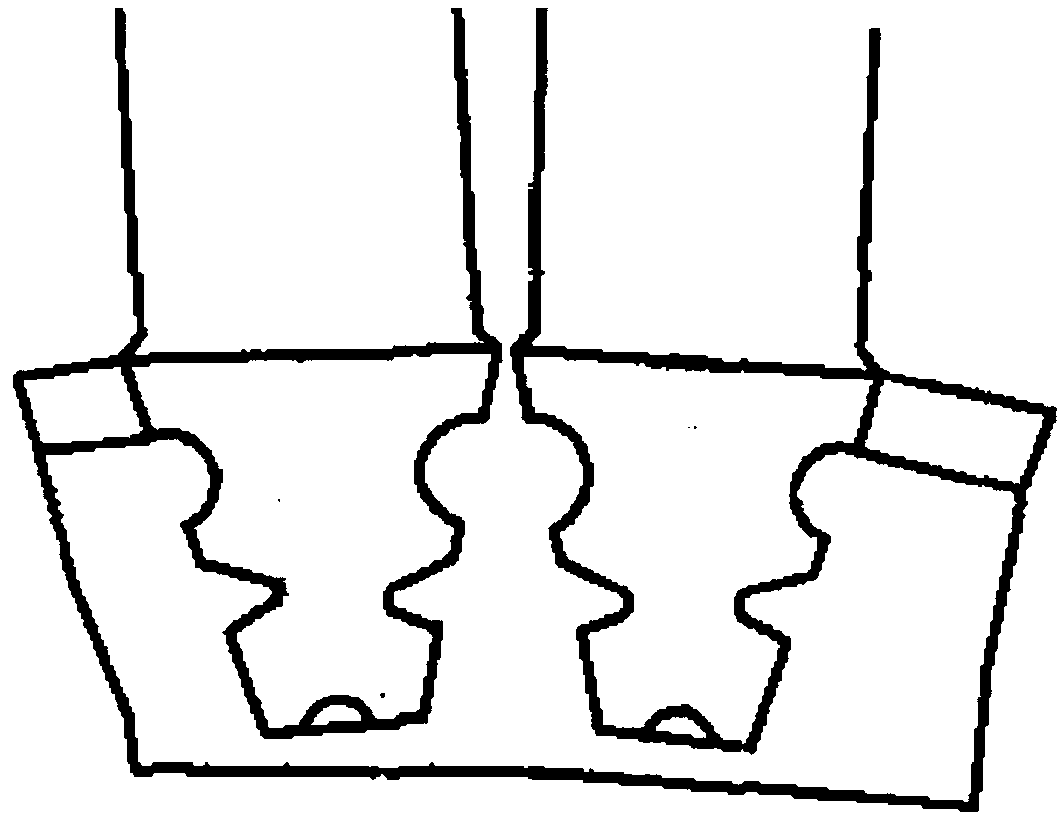

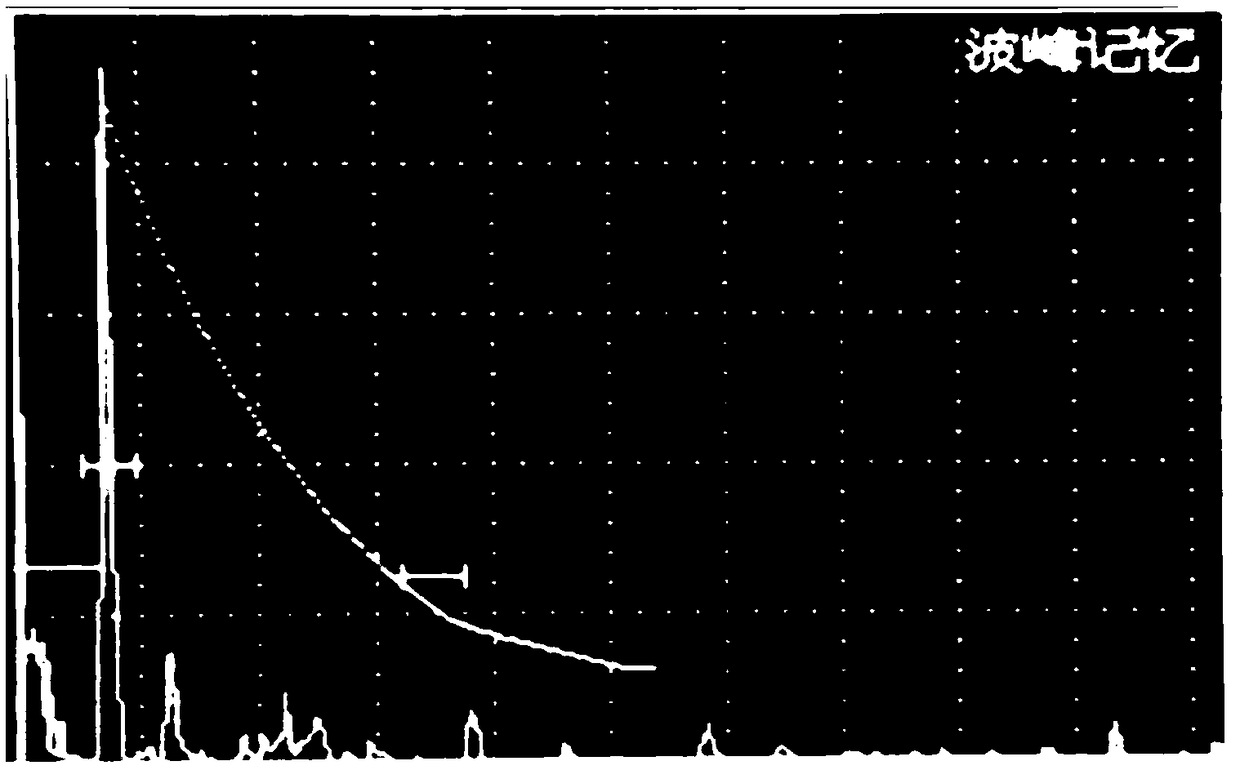

Longitudinal wave ultrasonic detection method for axial assembly fir-tree root of steam turbine

A detection method and steam turbine technology, which are applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc. , to achieve the effect of small moving distance, improving labor efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with examples and specific implementation methods. However, it should not be understood that the scope of the protection subject matter of the present invention is limited to the following embodiments, and all technologies implemented based on the contents of the present invention belong to the scope of the present invention. In order to avoid obscuring the essence of the present invention, well-known methods, procedures, procedures and components have not been described in detail.

[0034] In ultrasonic testing technology, the method of comparing with known artificial reflectors is usually used to determine the defect position and size of the inspected workpiece. The development of ultrasonic testing technology is always inseparable from the design and manufacture of reference test blocks. Therefore, it is necessary to develop and manufacture corresponding reference test blocks for the axial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com