Partition-based method for shadow defect extraction from single-sided light guide plate

An extraction method and technology for light guide plates, which are applied in the fields of optical testing flaws/defects, material analysis, image analysis, etc., can solve the problems of shadow defects of light guide plates, detection accuracy, efficiency and stability of artificial shadows, which are difficult to adapt to enterprises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Embodiment 1. A partition-based method for extracting shadow defects of a single-side incident light guide plate, such as Figure 1-18 shown, including the following steps:

[0089] Step 1. Considering that the shadow image needs to be observed from an overall perspective, it is necessary to collect the image F of the light guide plate through the surface frame camera; perform step 2;

[0090] The image of the light guide plate collected by the surface frame camera is dense and dense, with different sizes and uniform light emission, which is suitable for the detection and identification of image defects.

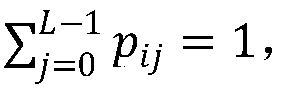

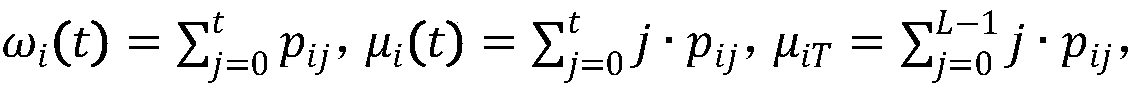

[0091] Step 2, use the region growing method to partition the image; obtain the image of i regions, and perform step 3;

[0092] Since the image F of the light guide plate may be warped, and the brightness of each part of the image is uneven, if the global detection is performed directly, it is very likely to cause false detection. Carry out partition detection; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com