tool for cutting

A cutting and tooling technology, which is applied in the field of reaming tools or milling tools, can solve the problems of cooling medium channel drilling and infeasibility, and achieve the effect of small structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

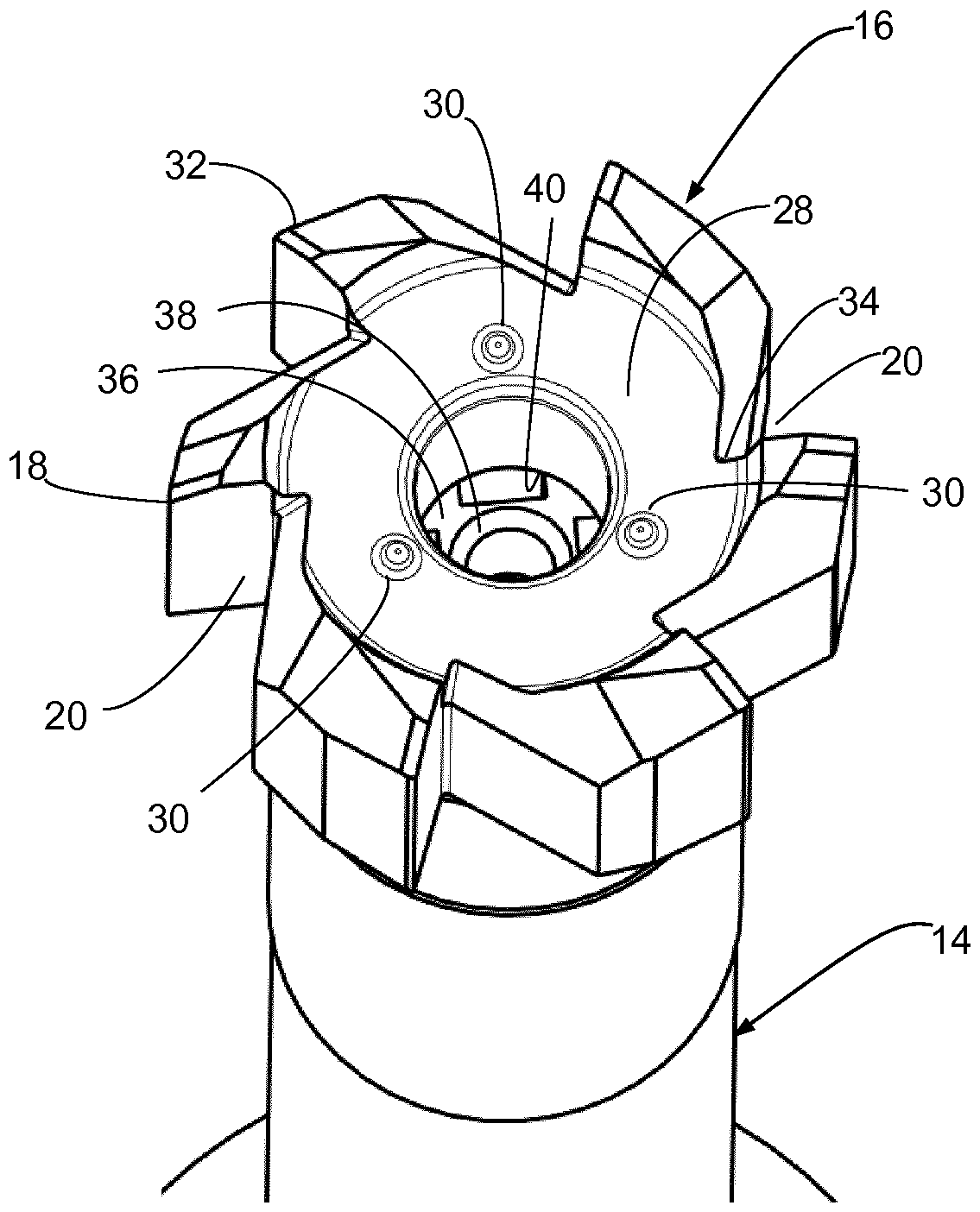

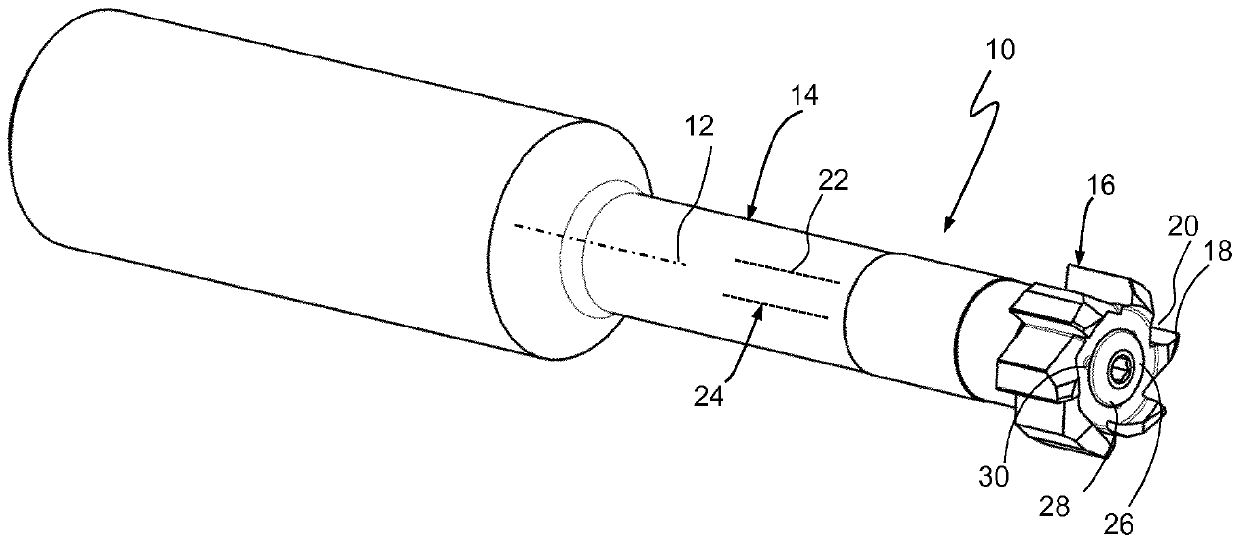

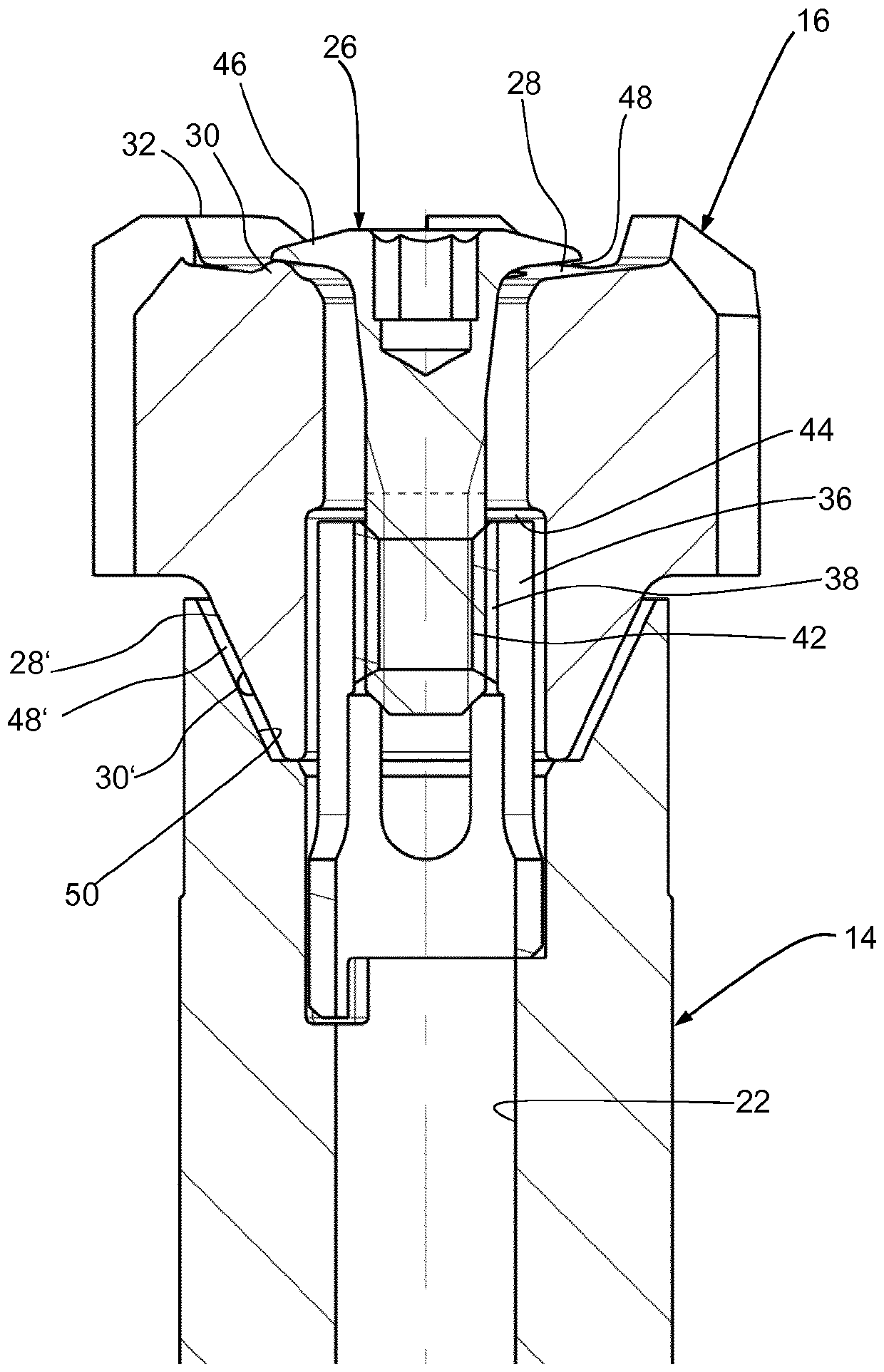

[0024] The reaming tool 10 shown in the drawing can be driven in rotation about its tool axis or longitudinal center axis 12 by means of a machine tool for finishing a prefabricated hole in a workpiece and moved axially forward therewith , in order to remove the reaming allowance by machining and thus produce a dimensionally accurate (passgenau) hole with a high surface quality. However, the tool axis can also be an axis of rotation for a workpiece about which the workpiece is moved in rotation for machining with a stationary machine tool.

[0025] as in figure 1 As shown in , the reaming tool 10 has a stepped cylindrical base body 14 which at its rear end can be clipped into the tool holder of the machine and at its front end carries a cutting head 16 . The cutting head 16 is formed as a sintered stamped part made of hard metal or cermet and is provided in a manner distributed over its circumference with a plurality of ground cutting edges 18 , each of which is associated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com