Device for processing workpiece surfaces by means of a laser beam and method for operating the device

A technology for processing workpieces and laser beams, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve problems such as unrealized safe implementation and display difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

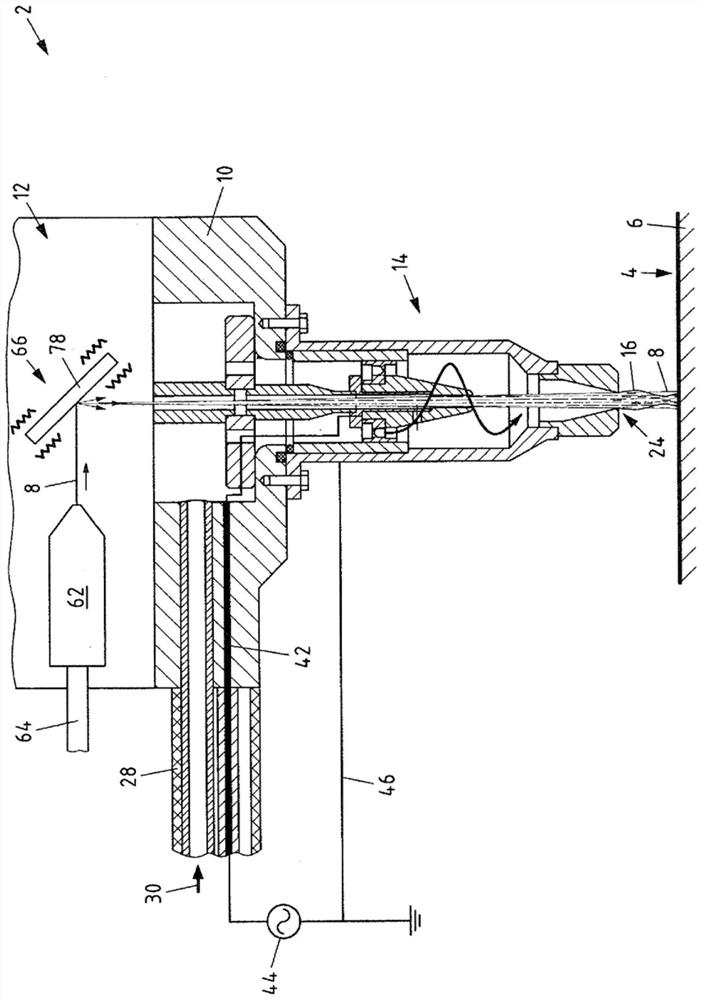

[0050] figure 1 Embodiments of the device according to the invention and the method according to the invention are shown schematically.

[0051] The device 2 for processing the surface 4 of a workpiece 6 with the aid of a laser beam 8 has a housing 10 in which a laser system 12 for supplying the laser beam 8 is integrated and to which is connected a device for generating an atmospheric pressure plasma The plasma nozzle 14 of the beam 16 .

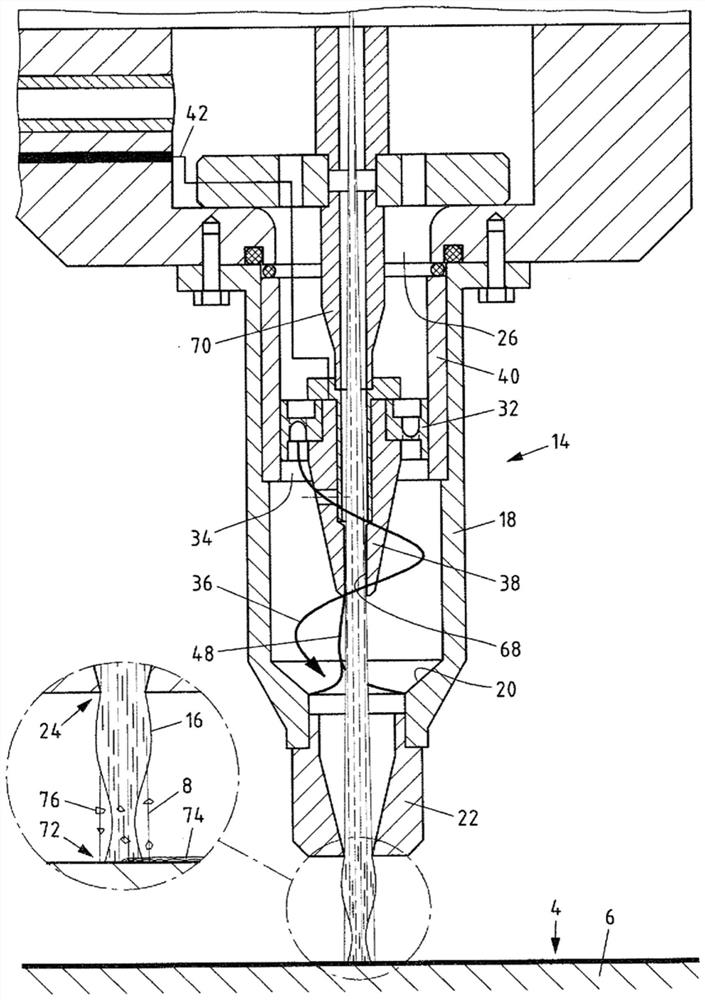

[0052] In the following, first according to figure 2 The structure and mode of operation of the plasma nozzle 14 are described, figure 2 shown in enlarged view figure 1 In the area of the plasma nozzle 14 of the device 2 .

[0053] The plasma nozzle 14 has a tubular housing 18 in the form of a nozzle tube made of metal, which is screwed onto the housing 10 of the device 2 . The nozzle tube 18 has at its one end a conical constriction 20 on which an exchangeable spray head 22 is mounted, the discharge opening of which forms a nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com