adhesive composition

A technology of adhesives and compositions, applied in the direction of adhesive types, ester copolymer adhesives, adhesives, etc., can solve problems affecting adhesive modulus and final strength, etc., to achieve excellent adhesion, high Effect of Adhesive Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0048] Specific examples include: butadiene-based rubbers such as vinyl-terminated butadiene rubber, chlorinated butadiene rubber, chlorosulfonated butadiene rubber, nitrile butadiene rubber (NBR), and styrene butadiene rubber ( SBR); chlorosulfonated polyethylene; silicone rubber; rubber copolymers such as styrene-butadiene-polymethylmethacrylate triblock copolymer, acrylonitrile-butadiene-styrene copolymer (or poly (acrylonitrile-butadiene-styrene)) and styrene-butadiene-styrene copolymer (or poly(styrene-butadiene-styrene)); or rubber derivatives, and they may be used alone Or two or more types thereof may be used in combination.

[0049] Additionally, the toughening agent may comprise a core-shell rubber or may comprise a non-core-shell rubber. Core-shell rubbers can be "core-shell" graft copolymers or "shellless" cross-linked rubber particles such as acrylonitrile-butadiene-styrene (ABS), methacrylate-butadiene-styrene ( MBS) and methacrylate-acrylonitrile-butadiene-sty...

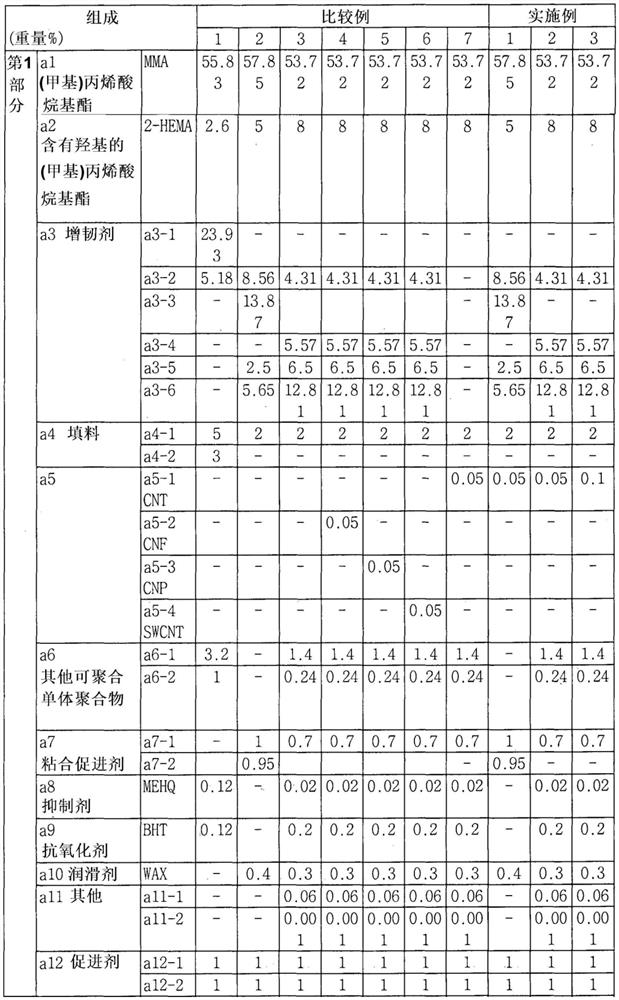

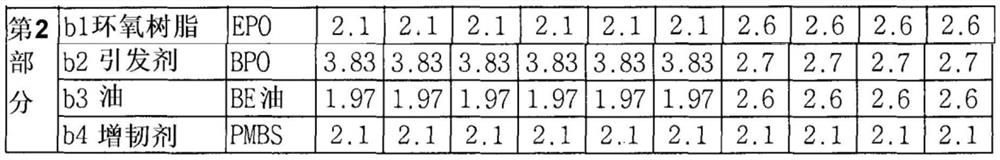

experiment example 1

[0150] The viscosity of the adhesive compositions prepared in Examples 1 to 3 and Comparative Examples 1 to 3 was measured using a Brookfield viscometer (model: DV1M-RV, spindle No. 7, 20 rpm). The results are shown in Table 2 below. In this case, for comparison of effects, the experimental results are also described together with a commercially available adhesive as a reference example.

[0151] Table 2

[0152]

[0153] As a result of the experiments, it was determined that the viscosity of the first part of the adhesive compositions of Examples 2 and 3 increased with an increase in the amount of carbon nanotubes.

experiment example 2

[0155] The adhesive compositions prepared in Examples 1 to 3 and Comparative Examples 1 to 3 were coated on various substrates shown in Table 3 below, and lap shear strength was measured by the method of ASTM D1002.

[0156] Specifically, the adhesive compositions prepared in Examples and Comparative Examples were respectively coated on plates with a size of 101.6 mm×177.8 mm×1.6 mm, and glass beads with a size of 250 μm were sprayed. At this point, application of the adhesive composition was performed by placing the first part of the adhesive composition into 10 parts of a 10:1 dual syringe cartridge dispenser and the second part into the dual syringe barrel In 1 portion of the dispenser, the adhesive composition is then quantitatively discharged through the static mixing tip. The jig and each board bonded with the adhesive composition were fixed at 25° C. for 24 hours, and then the fixed board was cut into a width of 25.4 mm to obtain 5 test pieces per board. Lap shear stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com