A low-temperature methanol washing energy-saving device and process

A technology of low-temperature methanol washing and energy-saving device, applied in the chemical industry, can solve the problems of uneven distribution of cooling capacity of low-temperature methanol washing, increase production and operation costs of enterprises, and difficulty in increasing system load, so as to facilitate process absorption and save renewable energy. Consume and ensure the effect of operating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

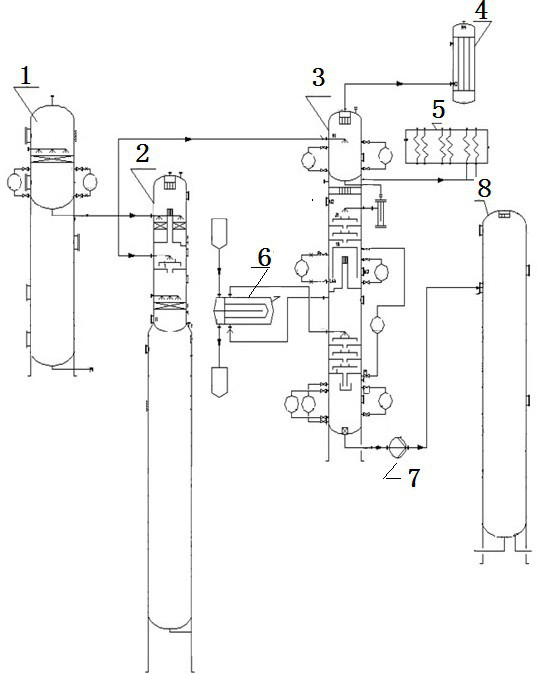

[0024] Such as figure 1 As shown, a low-temperature methanol washing energy-saving device includes a medium-pressure flash tower 1 connected to a reabsorption tower 2, and is characterized in that it also includes a semi-lean liquid stripping tower 3, which includes an upper tower, a middle tower and a lower tower , the medium pressure flash tower 1 is also connected to the upper tower of the semi-lean liquid stripping tower 3; the top of the upper tower is connected to the first heat exchanger 4, the bottom is connected to the middle tower, and the top of the middle tower is connected to the second heat exchanger 5, The bottom of the middle tower is connected to the lower tower through the third heat exchanger 6, and the bottom of the lower tower is connected to the carbon dioxide absorption tower 8.

[0025] The reabsorption tower is divided into four sections from bottom to top, one section is the air stripping section, which is stripped with nitrogen gas. The rich H that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com