Part drilling equipment for electric sanitation truck production

A technology of drilling equipment and sanitation vehicles, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., which can solve the problem of affecting the normal breathing of the staff, polluting the working environment of the staff, and not collecting debris and other problems, to achieve the effect of good drilling effect, good dust removal effect and high drilling precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

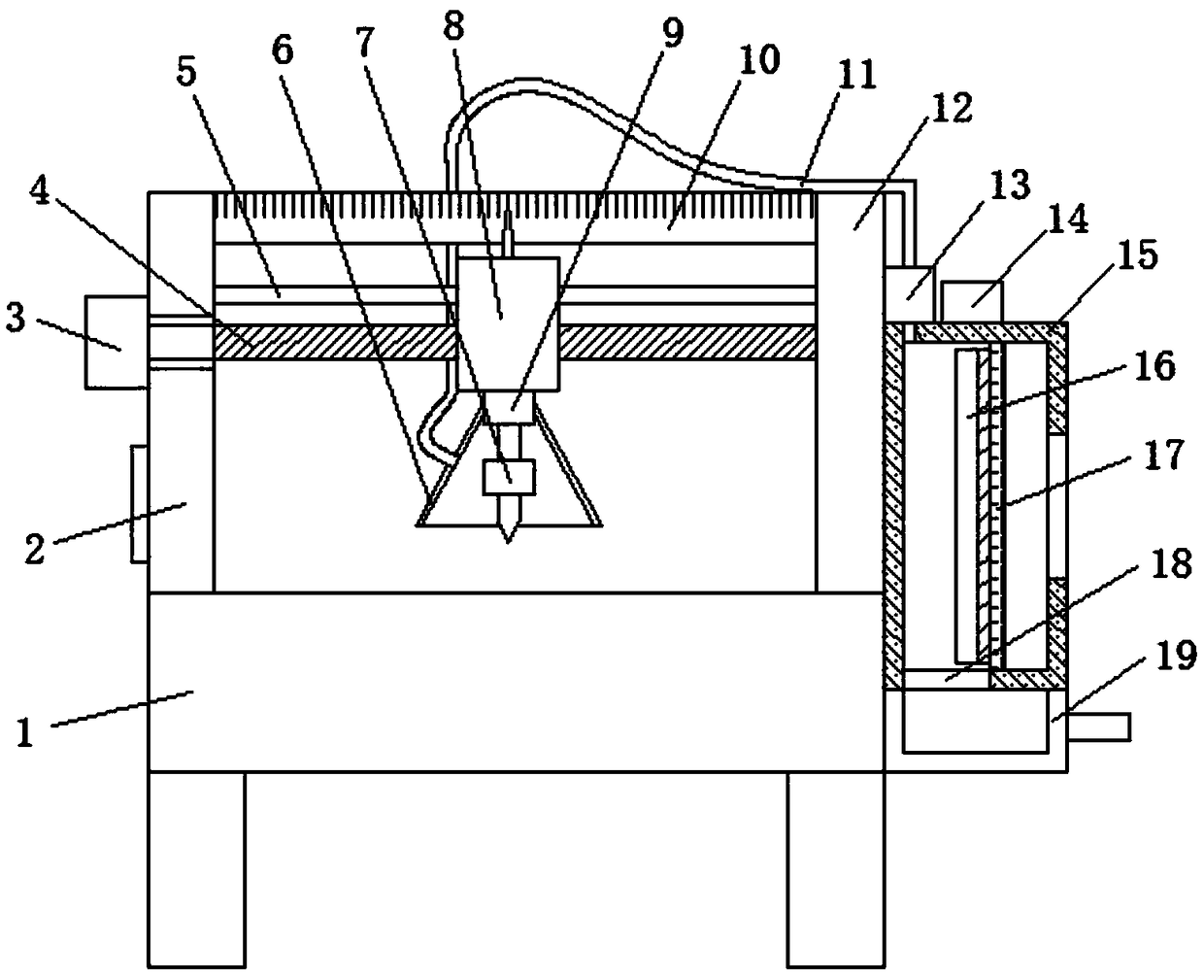

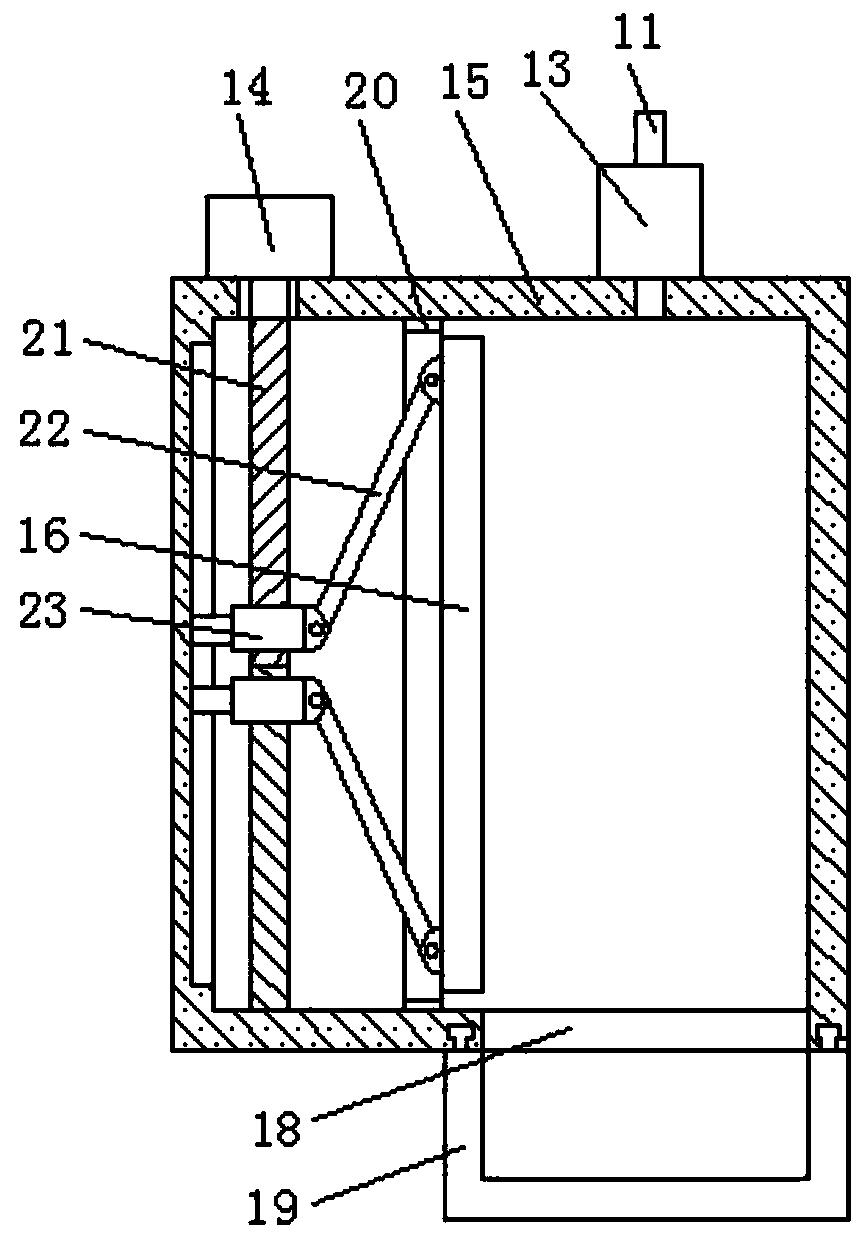

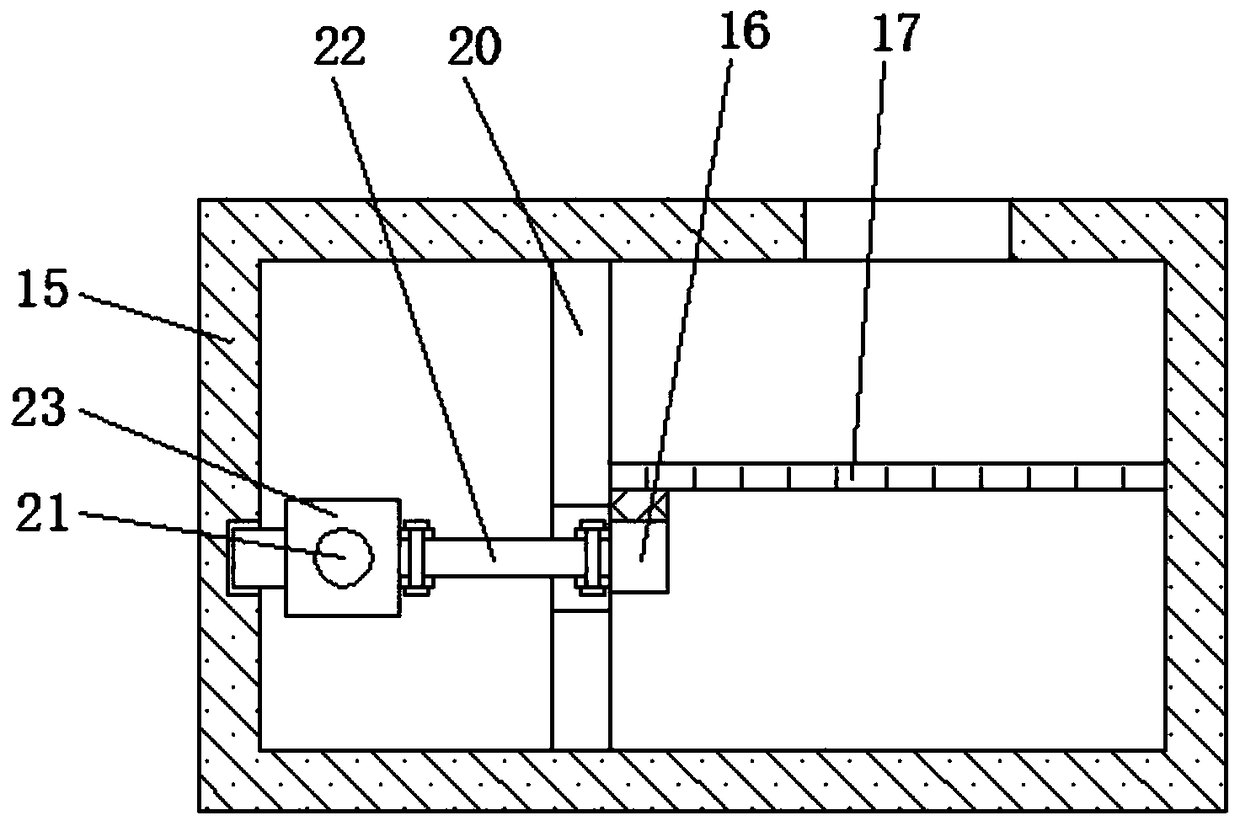

[0024] refer to Figure 1-3 , a kind of parts drilling equipment for the production of electric sanitation vehicles, including a workbench 1, a first side plate 2 and a second side plate 12 are respectively fixed on both sides of the top surface of the workbench 1, and the upper end of the first side plate 2 The first motor 3 is fixed on the side wall of the first motor 3, the output shaft of the first motor 3 is connected with the first lead screw 4, and one end of the first lead screw 4 passes through the first side plate 2 and is connected to the side of the second side plate 12 in rotation. On the wall, the first leading screw 4 is provided with a movable seat 8, the first leading screw 4 is connected with the movable seat 8 by threads, the bottom surface of the movable seat 8 is fixed with a cylinder 9, and the output end of the cylinder 9 is fixed with a second motor 7, The output shaft of the second motor 7 is connected with a drill bit, and a trumpet-shaped dust collec...

Embodiment 2

[0026] Such as Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a slide bar 5 is provided above the first lead screw 4, and the two ends of the slide bar 5 are respectively fixed on the ends of the first side plate 2 and the second side plate 12. On the side wall, the movable seat 8 is slidably connected to the slide bar 5 .

Embodiment 3

[0028] Such as Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a scale 10 is provided above the slide bar 5, and the two ends of the scale 10 are respectively fixed on the side walls of the first side plate 2 and the second side plate 12. On, the top of the movable seat 8 is provided with a pointer, and the pointer and the scale 10 cooperate with each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com