A kind of pine-based biomass activated carbon and its preparation method and application in electrochemical energy storage

A biomass and activated carbon technology, applied in the direction of inorganic chemistry, chemical instruments and methods, carbon compounds, etc., can solve problems such as narrow layer spacing, difficulty in meeting the application requirements of sodium-ion battery anode materials, and slow mass transfer rate of biomass activated carbon. Achieve the effect of wide layer spacing, high economic value and benefit, and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Activated carbon preparation:

[0034] (1) Carbon source preparation: select pine trees in Yuelu Mountain in Changsha, Hunan Province as the carbon source of the precursor, peel off the bark, take the main woody part, wash it with distilled water three times, dry it in an oven at 120°C for 24 hours, and then crush it. Sieve out 40-80 mesh pine powder.

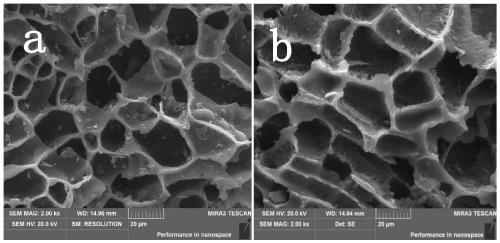

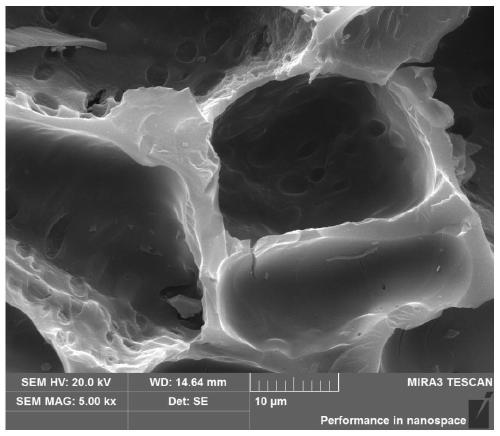

[0035] (2) Hydrothermal treatment: Weigh 1g of NaOH in 80mL of water, transfer it to a 100mL reactor, take 1g of the carbon source in (1) in the reactor, seal it, and place it in a blast drying oven at 200°C for water Heat 6h. Hydrothermal finish, cooling, drying in blast drying box, obtains solid mixture, the scanning electron microscope of the pine tree powder before and after hydrothermal treatment is as follows: figure 1 As shown, it can be observed that the pore structure on the surface of pine powder after hydrothermal treatment is more and more uniform, indicating that the hydrothermal process has an important i...

Embodiment 2

[0052] Activated carbon preparation:

[0053] (1) Carbon source preparation: select pine trees in Yuelu Mountain in Changsha, Hunan Province as the carbon source of the precursor, peel off the bark, take the main woody part, wash it with distilled water three times, dry it in an oven at 120°C for 24 hours, and then crush it. Sieve out 40-80 mesh pine powder.

[0054] (2) Hydrothermal treatment: weigh 4g ZnCl 2 Transfer 80mL of water to a 100mL reaction kettle, take 1g of the carbon source in (1) in the reaction kettle, seal it, and place it in a forced air drying oven at 240°C for 10h. After hydrothermal completion, cool and dry in a blast drying box to obtain a solid mixture.

[0055] (3) Carbonization: take the mixed solid obtained in (2), and in an argon atmosphere, raise the temperature to 1000°C at 10°C / min, keep it warm for 1.5h, and after cooling to room temperature, the product is washed successively with concentrated hydrochloric acid and secondary water to Neutra...

Embodiment 3

[0062] Activated carbon preparation:

[0063] (1) Carbon source preparation: select pine trees in Yuelu Mountain in Changsha, Hunan Province as the carbon source of the precursor, peel off the bark, take the main woody part, wash it with distilled water three times, dry it in an oven at 120°C for 24 hours, and then crush it. Sieve out 40-80 mesh pine powder.

[0064] (2) Hydrothermal treatment: weigh 2g K 2 CO 3 Transfer 80mL of water to a 100mL reaction kettle, take 1g of the carbon source in (1) in the reaction kettle, seal it, and place it in a forced air drying oven at 180°C for 6 hours. After hydrothermal completion, cool and dry in a blast drying box to obtain a solid mixture.

[0065] (3) Carbonization: take the mixed solid obtained in (2), and in an argon atmosphere, heat up to 1200°C at 10°C / min, keep it warm for 1.5h, and after cooling to room temperature, the product is washed with concentrated hydrochloric acid and secondary water to Neutral, then filtered and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com