H-type vertical axis wind turbine with coaxial jet flow blades

A coaxial jet, vertical axis technology, used in wind turbines, wind turbines at right angles to the wind direction, motors, etc., can solve the problems of large energy input and low application prospects, reduce input, inhibit flow separation, The effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

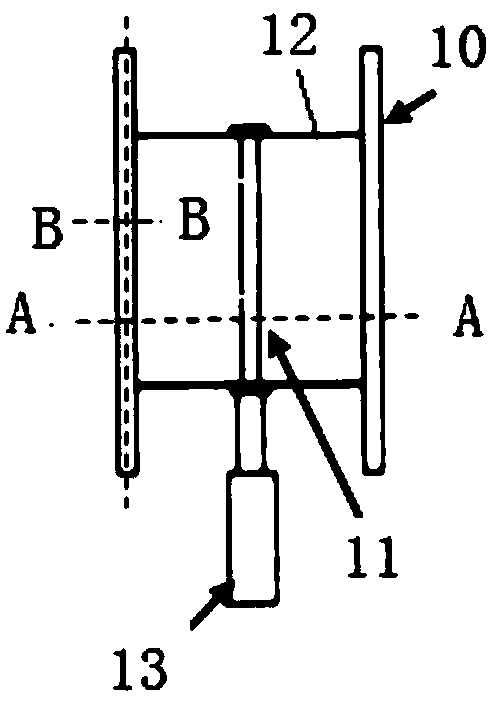

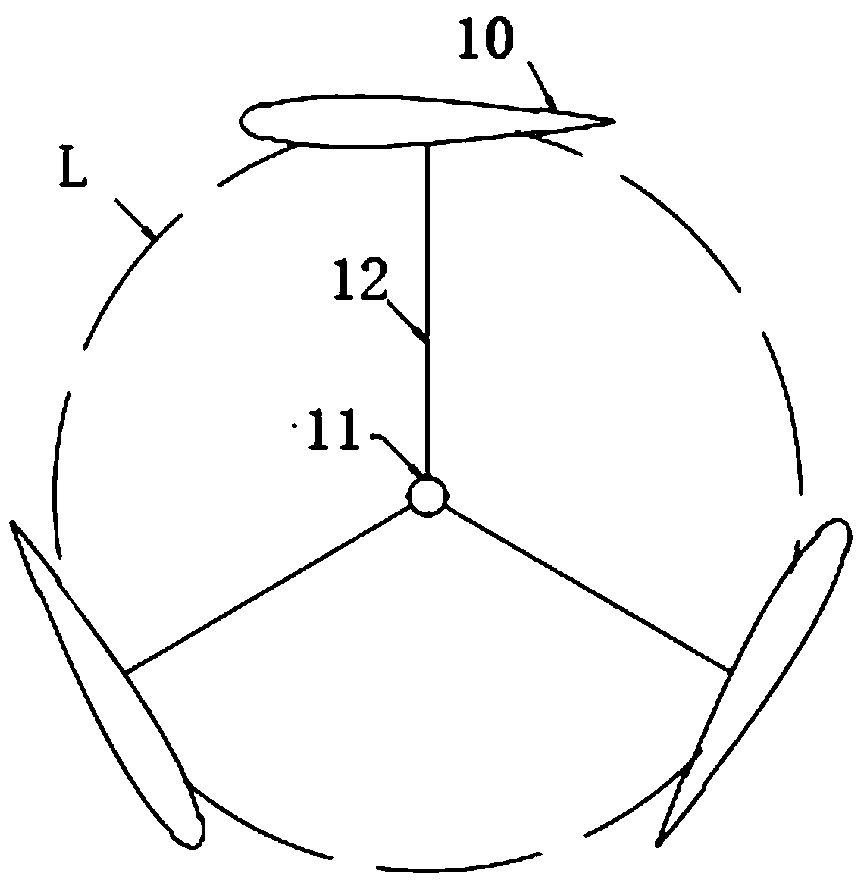

[0020] Such as figure 2 , 3, a H-type vertical axis wind turbine with coaxial jet blades, including jet blades 10, shaft 11, connecting rod 12. A plurality of coaxial jet blades 10 are respectively connected to a rotating shaft 11 through a connecting rod 12 , and the rotating shaft 11 is connected to a generator 13 . A plurality of coaxial jet blades 10 move along the rotation track L, and drive the generator 13 to rotate and generate electricity through the rotating shaft 11 .

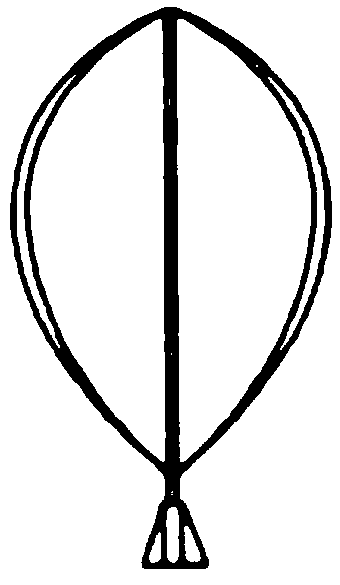

[0021] Such as Figure 4 to Figure 6 As shown, a high-pressure air cavity 1 is set up near the leading edge inside the coaxial jet blade 10, and a low-pressure air cavity 2 is set up near the trailing edge, and the airfoil surface of the coaxial jet blade 10 is located on both sides of the airfoil surface at a distance of 3% of the chord length from the leading edge. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com