Quantitative research method for inner wall abrasion of thick-wall cylinder

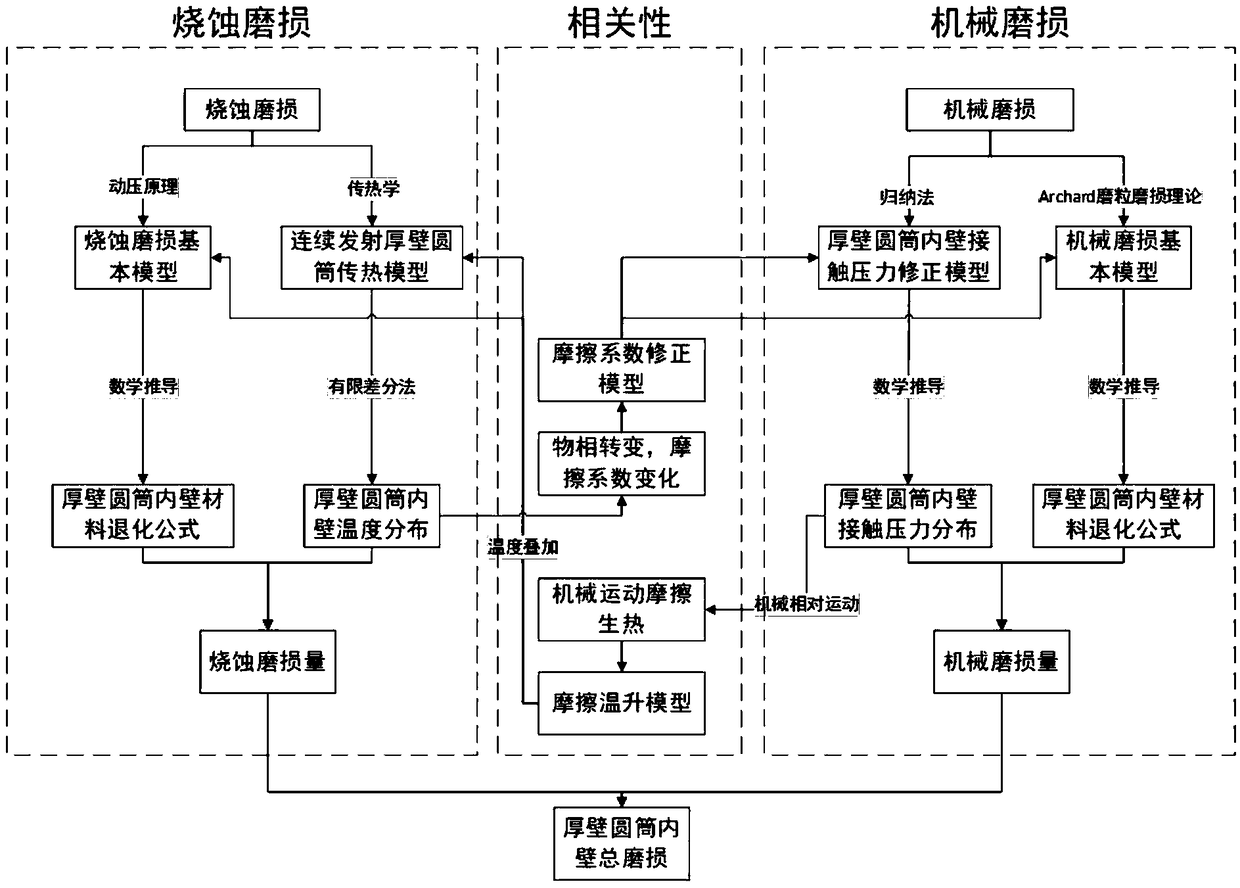

A wear amount and cylinder technology, applied in the field of friction and wear, can solve the problems of difficult measurement of dynamic wear of thick-walled cylinder materials, missing sources of material degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

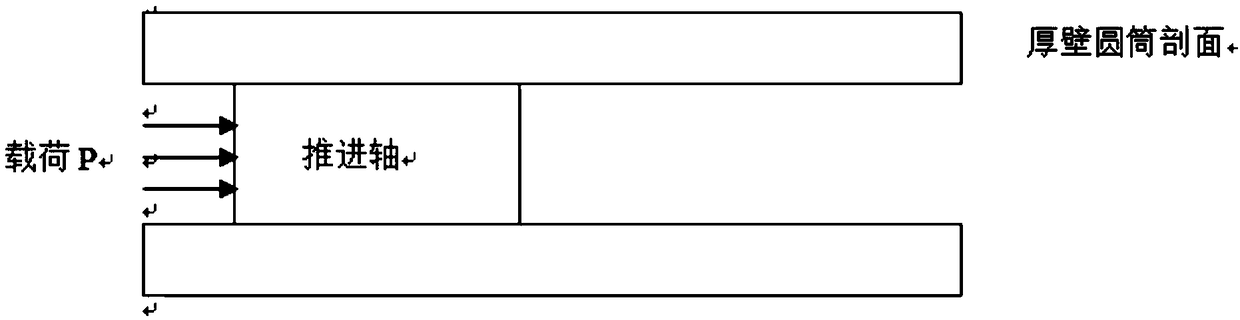

[0042] Taking a shaft-drum device as the research object, its structure is as follows: figure 1 As shown, the hexahedron reduced-integration element is used to carry out discretization modeling of the thick-walled cylinder and the propulsion shaft.

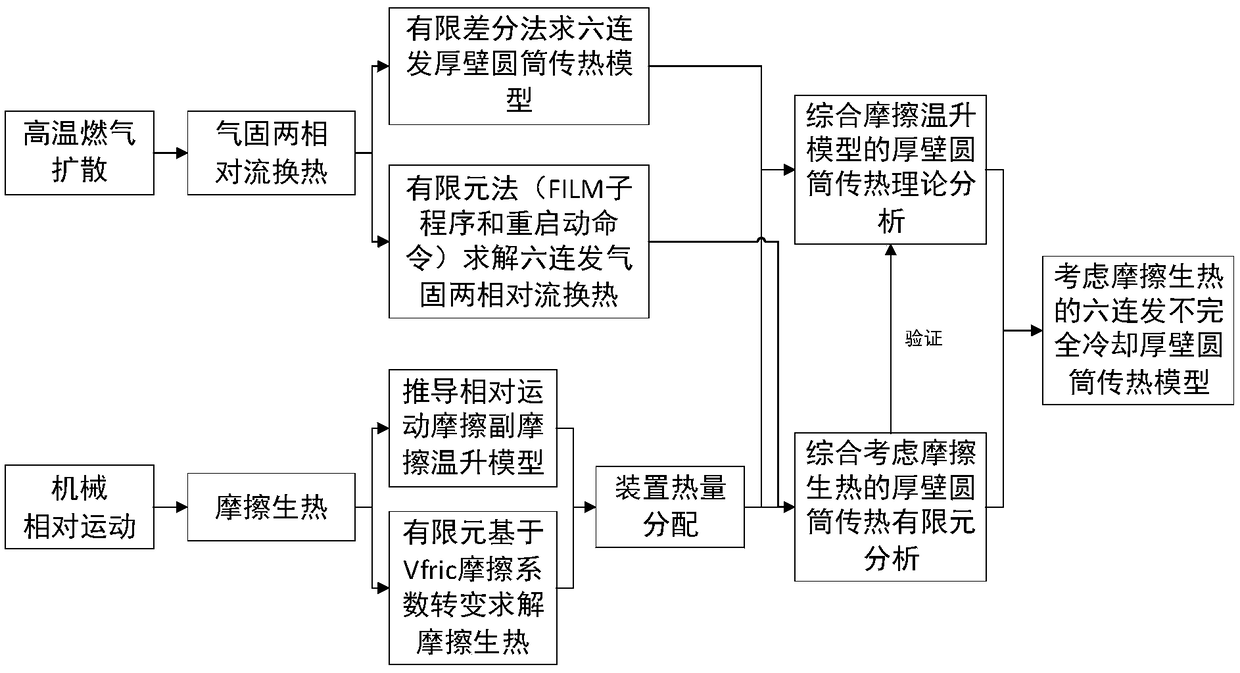

[0043] Using the implicit integral algorithm provided by the ABAQUS secondary development module, based on the thermal displacement coupling analysis step, the ABAQUS secondary development FILM subroutine is introduced to simulate the convective heat transfer process between the thick-walled cylinder and the high-temperature gas, and the inner wall of the thick-walled cylinder is obtained. Preliminary temperature distribution, and then by establishing a friction temperature rise model to approximate the frictional heat distribution process of the thrust shaft friction pair of the thick-walled cylinder to correct the temperature distribution on the inner wall of the thick-walled cylinder, as shown in image 3 As shown, and based on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com