Intelligent vacuum oil liquid filtering dewatering system

An oil and vacuum technology, applied in the direction of filtration and separation, filtration circuit, lubricating composition, etc., can solve the problems that affect the efficiency of oil removal and water removal, damage lubricating oil, affect the circulation of lubricating oil, etc., and achieve fast oil removal Filtration and water removal operations, saving production costs, and improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

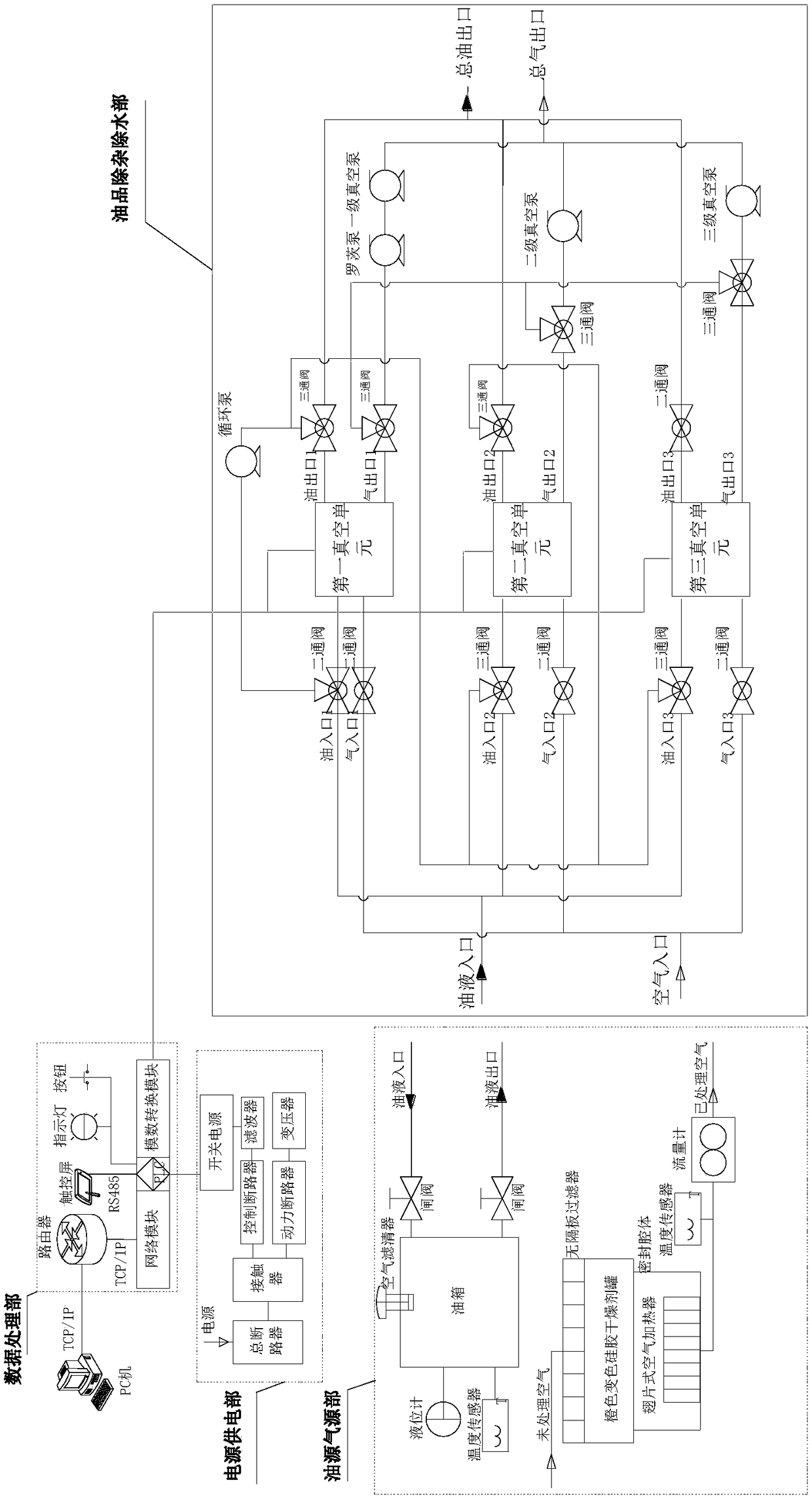

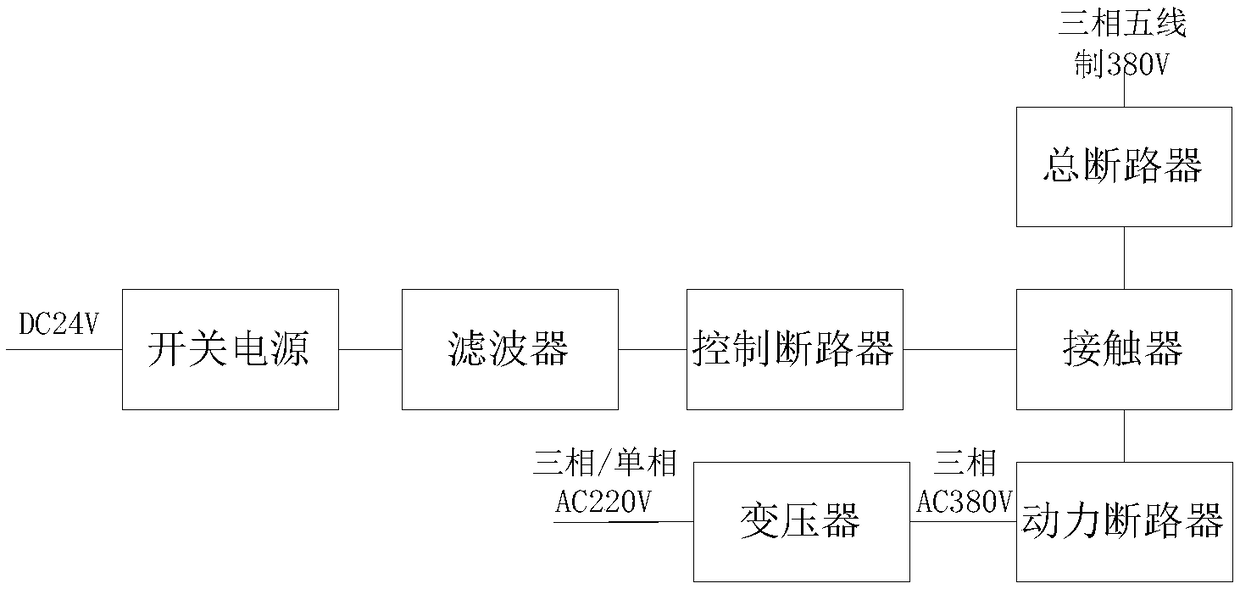

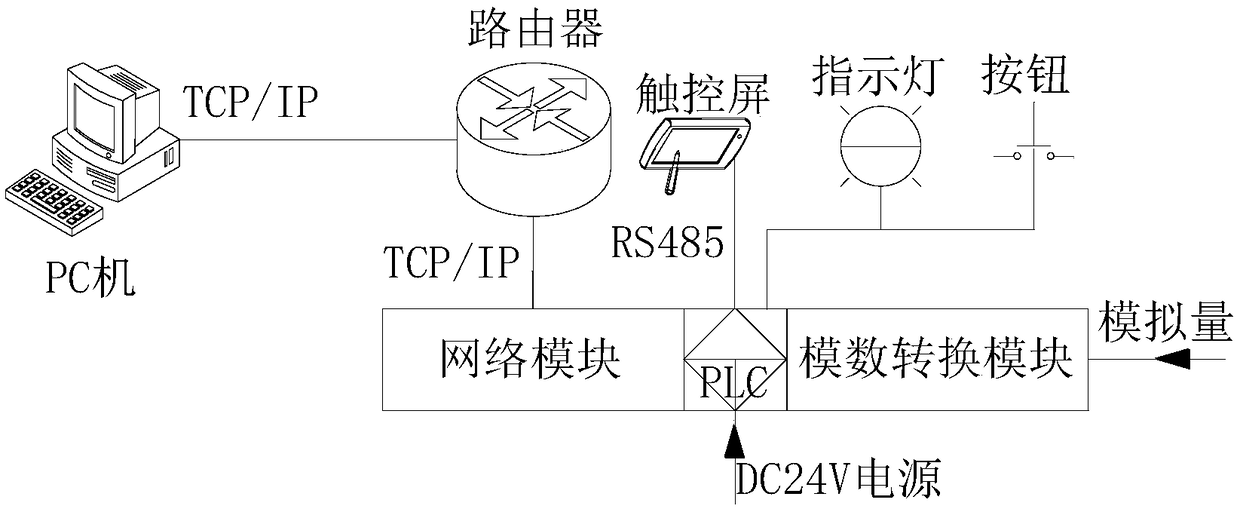

[0035]An oil vacuum intelligent filtration and water removal system, including a power supply unit responsible for the input and output of different types of power supplies required by the platform, and an oil source and air source power unit responsible for the oil source and air source of the platform. and an oil liquid impurity removal and water removal part for filtering impurities and water in the oil liquid, the oil source air source power part includes an oil source part for providing the oil source for the oil liquid impurity removal and water removal part to be treated and for The oil removal and water removal part provides the dry hot air air source part, and the oil source and air source power part communicates with the oil removal and water removal part through the oil passage of the oil source part and the air passage of the air source part respectively, The oil source part forms a circuit with the oil liquid removal and water removal part, and the power supply par...

Embodiment 2

[0047] An oil vacuum intelligent filtration and water removal system, including a power supply unit responsible for the input and output of different types of power supplies required by the platform, and an oil source and air source power unit responsible for the oil source and air source of the platform. and an oil liquid impurity removal and water removal part for filtering impurities and water in the oil liquid, the oil source air source power part includes an oil source part for providing the oil source for the oil liquid impurity removal and water removal part to be treated and for The oil removal and water removal part provides the dry hot air air source part, and the oil source and air source power part communicates with the oil removal and water removal part through the oil passage of the oil source part and the air passage of the air source part respectively, The oil source part forms a circuit with the oil liquid removal and water removal part, and the power supply pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com