Simple and rapid flue gas cooling and dust removal pretreatment device and method

A pretreatment device and rapid cooling technology, applied in the field of advanced devices, can solve the problems of complex structure, inconvenient transportation, bulky and other problems, and achieve good pre-dust removal effect, fast installation and connection, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

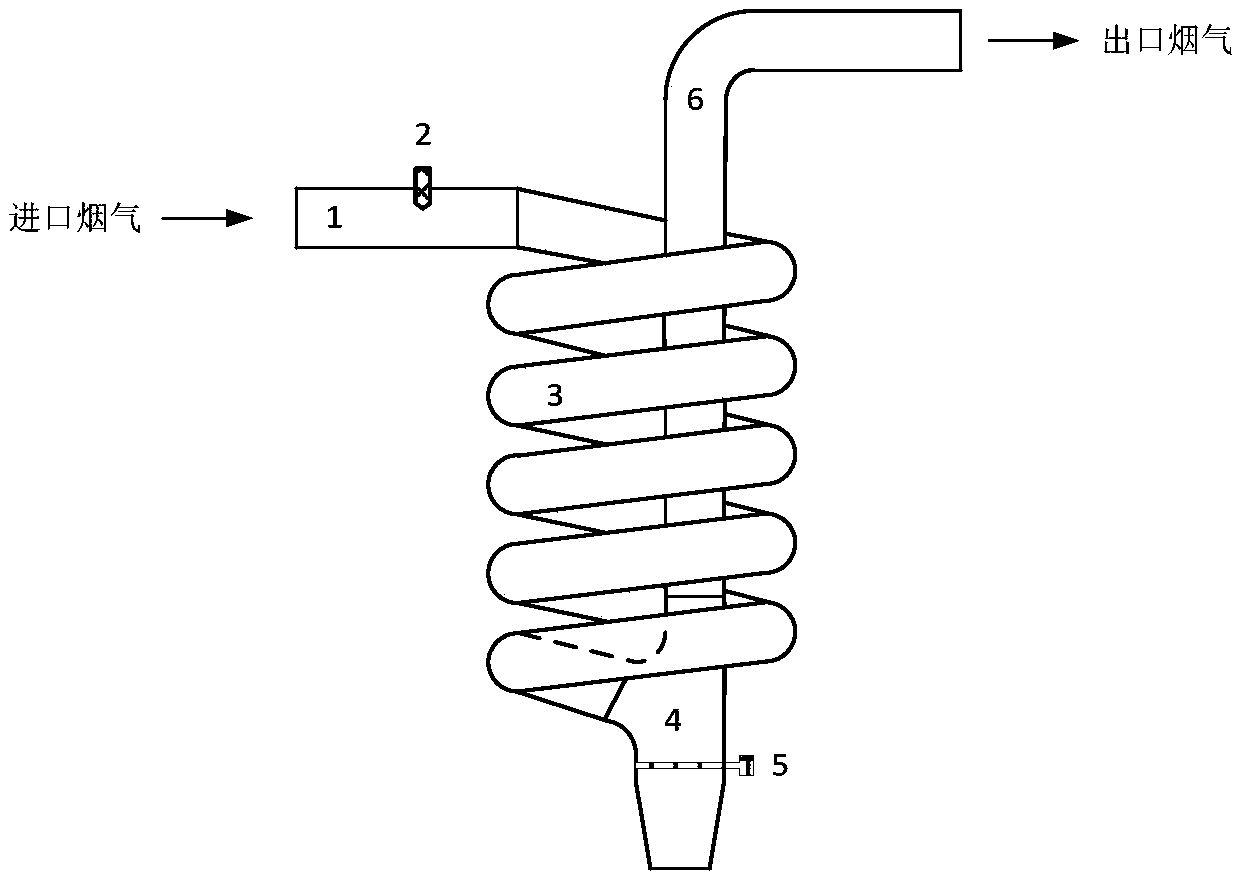

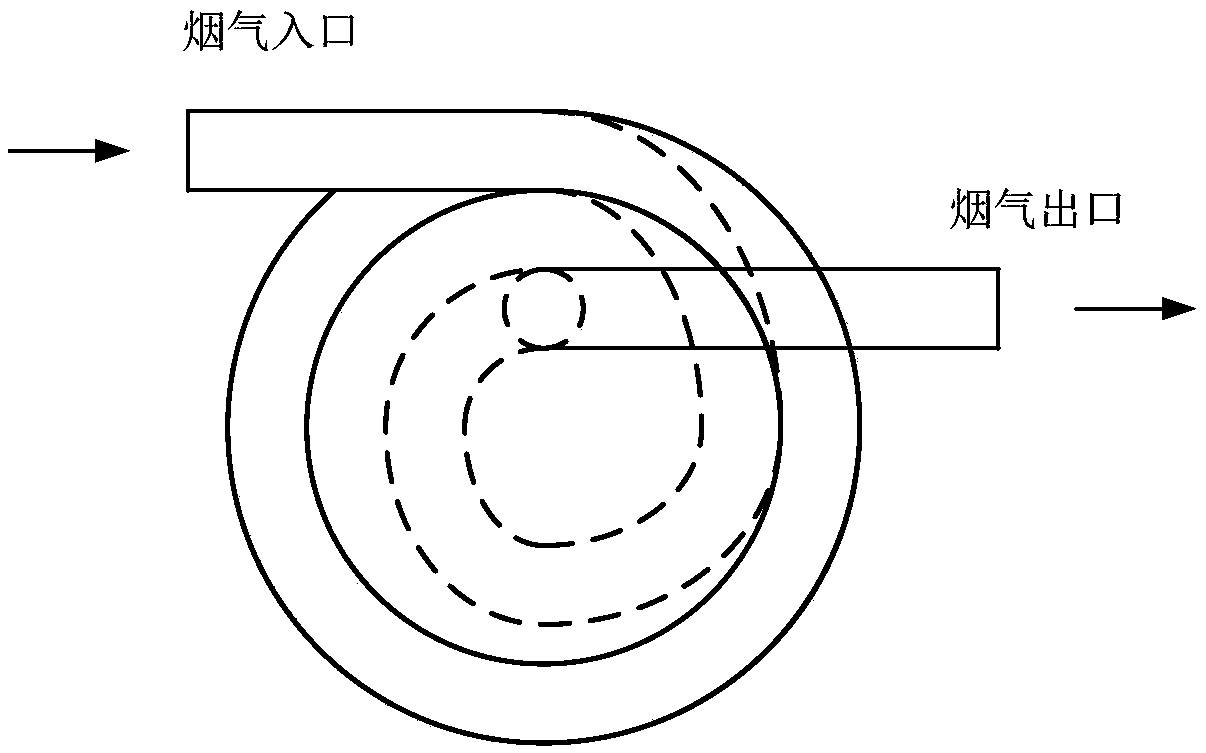

[0028] Such as Figure 1~2 As shown, a simple flue gas rapid cooling and dust removal pretreatment device includes a flue gas inlet pipe 1, a nozzle 2, a spiral flue 3, ash discharge pipe fittings 4, ash removal valve 5 and a flue gas discharge pipe 6, the described The flue gas inlet pipe 1 is connected to the spiral flue 3, and a nozzle 2 is arranged on the flue gas inlet pipe 1. The outlet of the spiral flue 3 is connected to the ash discharge pipe 4 and the flue gas discharge pipe 6 respectively. The ash removal valve 5 is arranged on the ash discharge pipe fitting 4.

[0029] The present invention utilizes a pilot-scale flue gas purification device in a laboratory for experimental research. There is a rotary kiln to roast domestic garbage to provide waste incineration flue gas, and the flue gas volume is 300Nm 3 / h. A flue gas inlet pipe 1 with a diameter of 100mm is connected to the outlet of the rotary kiln, and the flue gas velocity is about 10.6m / s. A stainless st...

Embodiment 2

[0033] This example utilizes the device installed in example 1 to carry out the experiment. Incinerate domestic garbage and coal-fired mixed samples in a rotary furnace, the temperature of the flue gas at the outlet of the rotary kiln is 900 ° C, the flow velocity of the flue gas in the flue gas inlet pipe 1 is 10 m / s; the dust concentration is 3.0 g / Nm 3 Spray cooling water at a temperature of 20°C into the spiral flue through the nozzle at a rate of 1.5L / min. The number of spiral turns of the spiral flue is within 5, and the angle between the inclination angle of the spiral flue and the horizontal plane is 30 degrees; The flue gas temperature measured at the detection port of the spiral flue riser is 350°C, and the dust concentration is 1.0g / Nm 3 . The results show that after the cooling water cooling and spiral tube dust removal, the flue gas temperature is reduced by 550°C, and the dust removal efficiency is about 66.7%.

Embodiment 3

[0035] This example utilizes the device installed in example 1 to carry out the experiment. Incinerate domestic waste and coal-fired mixed samples in a rotary furnace, the temperature of the flue gas at the outlet of the rotary kiln is 900°C, the flow velocity of the flue gas in the flue gas inlet pipe (1) is 15m / s; the dust concentration is 3.0g / Nm 3 Spray cooling water at a temperature of 20°C into the spiral flue through the nozzle at a rate of 2.0L / min. The number of spiral turns of the spiral flue is within 20, and the angle between the inclination angle of the spiral flue and the horizontal plane is 5 degrees; The flue gas temperature measured at the detection port of the spiral flue riser is 180°C, and the dust concentration is 0.8g / Nm 3 . The results show that after the cooling water cooling and spiral tube dust removal, the flue gas temperature is reduced by 720°C, and the dust removal efficiency is about 73.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com