Upper box-type dense cooling device

A cooling device, box-type technology, applied in the direction of workpiece cooling device, workpiece surface treatment equipment, metal rolling, etc., can solve the problems of water resource waste, response delay, etc., to achieve reduced impact, fast response speed, and good cooling uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

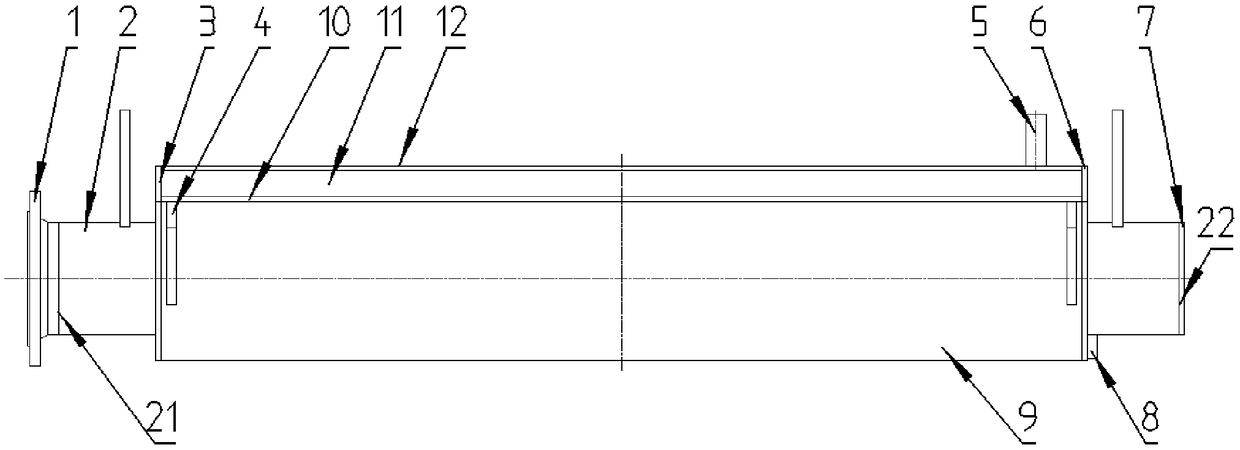

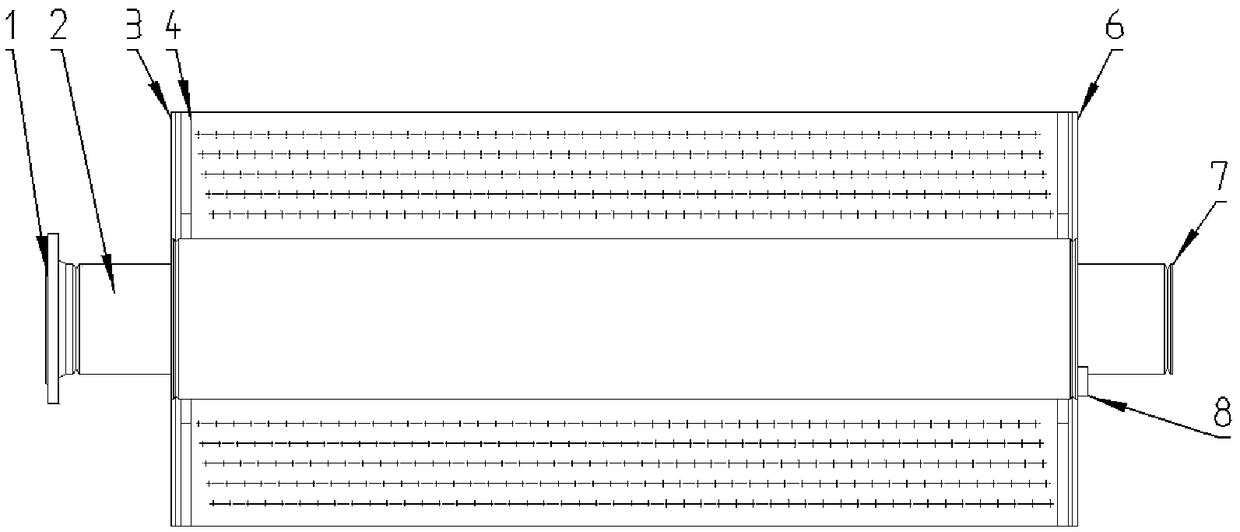

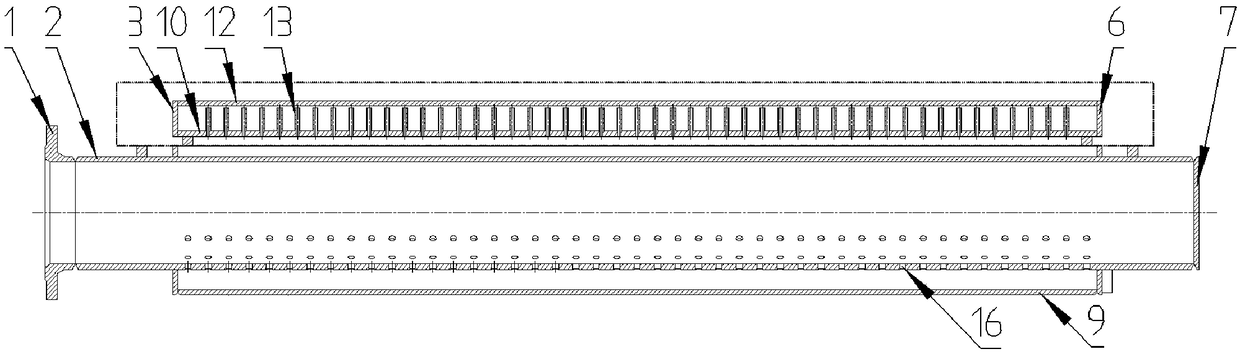

[0028] Such as figure 1 As shown, the top-mounted box-type intensive cooling device for strip steel controlled cooling of the present invention includes a water inlet header 2 and a water spray device main body 9 sleeved on the water inlet header 2 . The second end 21 of the water inlet header 2 is connected with the connecting flange 1 coaxially, and the first end 22 of the water inlet header 2 is fixedly connected with the header end plate 7 to form a part of the water inlet header together; The lower part of the pipe 2 is provided with damping holes 16 uniformly distributed in the circumferential direction to ensure the uniformity of water flow in the length direction of the cooling device; They are respectively fixedly connected with the side plate 3 on the water inlet side and the side plate 6 on the drain side to form the main part of the cooling device; The nozzle installation hole 17 is used to install the dense nozzle 13; the height of the top of the nozzle 13 is hig...

Embodiment 2

[0036] Such as Figure 6 Shown is another embodiment of the specific embodiment.

[0037]The difference between the second embodiment of the present invention and the first embodiment is that the spray pipe mounting plate 10 connected to both sides on the sprinkler main body 9 is a whole, and the spray pipe mounting plate has a square hole 18, so that The cooling water passes through, and two buffer fixing plates 15 are connected between the nozzle mounting plate 10 and the top plate. The two buffer fixing plates 15, the nozzle mounting plate 10, and the top plate 12 form a cavity to reduce cooling when the cooling device starts and stops. The changing volume of water; the buffer plate 15 is fixedly connected to the buffer plate 14, so that when the cooling water enters the upper intensive cooling part from the main part of the cooling device, the direction of the water flow is changed from vertical upward to horizontal, so as to avoid the impact of the cooling water on the no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com