Preparation method of mulberry and rose fruit wine

A technology of mulberry and fruit wine, which is applied in the field of preparation of mulberry and rose fruit wine, can solve the problem of high equipment requirements, and achieve the effects of improved comprehensive utilization rate, significant increase in farmers' income, and excellent nutrition and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

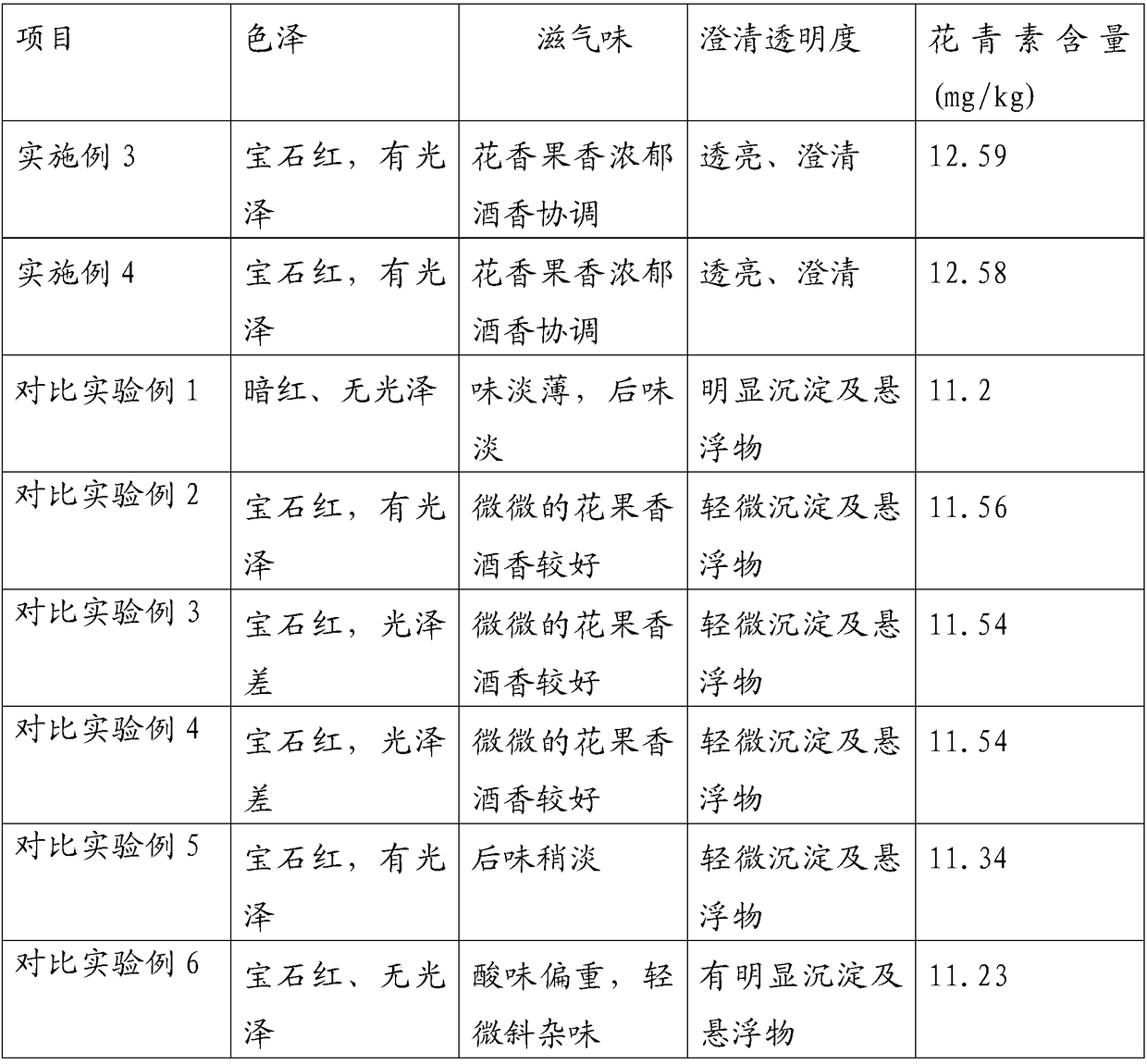

Examples

Embodiment 1

[0030] (1) Proportion of raw materials: according to parts by weight, take 9 parts of mulberry powder, 1 part of rose pollen, add 100 parts of water, stir and mix until completely uniform, add active yeast, the addition amount is 0.8wt% of the fermentation liquid, and stir again .

[0031] (2) Fermentation: put the mixed raw materials into the fermenter, the loading volume is 85%, add lemon powder to adjust the acidity to be pH3.8, the amount of sugar added on the first day of fermentation is 16wt% of the sugar content of the fermentation mixture, and the second day Add sugar to 23wt%, and start fermentation at a temperature of 22-24°C; on the fourth day of fermentation, after pomace floats and bubbles appear, stir at least once a day, stop stirring when there are no bubbles, and the total fermentation time is not less than 21 days.

[0032] (3) Post-fermentation: filter the fermented fermentation broth, continue post-fermentation at 18-21°C for no less than one month, and fil...

Embodiment 2

[0035] (1) Proportion of raw materials: according to parts by weight, take 8 parts of mulberry powder, 2 parts of rose pollen, add 100 parts of water, stir and mix until completely uniform, add active yeast, the addition amount is 1.2wt% of the fermentation liquid, and stir again .

[0036] (2) Fermentation: put the mixed raw materials into a fermenter, with a volume of 82%, add lemon powder to adjust the acidity to be pH3.5, the amount of sugar added on the first day of fermentation is 18wt% of the sugar content of the fermentation mixture, and the second day Add sugar to 25wt%, and start fermentation at a temperature of 22-24°C; on the fourth day of fermentation, after pomace floats and bubbles appear, stir at least once a day, stop stirring when there are no bubbles, and the total fermentation time is not less than 21 days.

[0037] (3) Post-fermentation: filter the fermented fermentation broth, continue post-fermentation at 18-21°C for no less than one month, and filter to...

Embodiment 3

[0040] 1. Preparation of dried mulberries:

[0041] (1) Take fresh mulberries and wash them with flowing water, centrifugally shake off the water, spread them flat on filter cloth or filter net with a thickness of 1.5cm, send them into a hot air circulation drying oven, and dry them at 68°C for 1 hour; Dehumidification.

[0042] (2) Lower the temperature of the drying oven to 65° C. and dry for 3 hours.

[0043] (3) Reduce the temperature of the drying oven to 60° C. and dry for 4 hours.

[0044] (4) Reduce the temperature of the drying oven to 55° C. and dry for 3 hours.

[0045] (5) Finally, the temperature of the drying oven was raised to 65° C. and dried for 1 hour to obtain the dried mulberries. The criterion for judging the drying end point is that the dried mulberries have a water content below 10 wt%, and they are crushed by hand.

[0046] 2. Preparation of dried roses:

[0047] Rinse the fresh roses with running water, centrifugally shake off the water, spread th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com