Iron coke preparation method by high titanium type schreyerite sintering return mine and prepared iron coke thereof

A technology for sintering and returning ore and vanadium-titanium ore, which is applied in the field of iron and coke, can solve the problems of re-consumption of fuel and increase of iron-making costs, and achieve the effects of reducing processing costs, improving coking effects, obvious application prospects and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

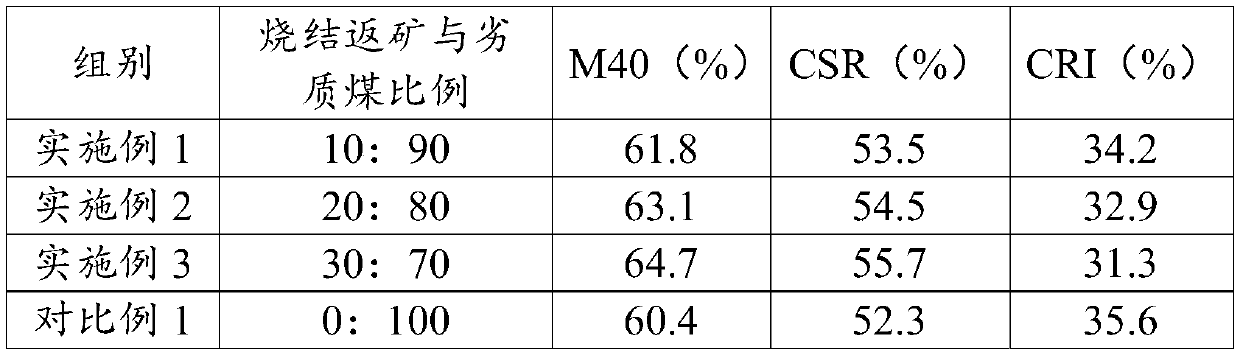

Embodiment 1

[0059] A method for preparing iron coke by sintering and returning high-titanium vanadium-titanium ore, said method comprising the following steps:

[0060] (a), first sieve the high-titanium vanadium-titanium ore sintered and returned ore, collect the returned ore with a particle size of less than 1 mm, and then mix the returned ore with a particle size of less than 1 mm and low-quality coal at a mass ratio of 10:90, The mixing of the returned ore with a particle size of less than 1mm and inferior coal is mechanically mixed in a V-shaped mixer, the mixing speed is 10r / min, and the mixing time is 8min to obtain the mixture A;

[0061] (b), the mixture A is added into a mold whose size is (5mm) × (5mm) × (5mm), and hot-pressed at 300°C and under a pressure of 120kN to obtain the coal-formed material, and then the coal-formed material and The high-quality coal is mixed with a mass ratio of 20:80, and the mixing of the shaped coal material and the high-quality coal is mechanicall...

Embodiment 2

[0064] A method for preparing iron coke by sintering and returning high-titanium vanadium-titanium ore, said method comprising the following steps:

[0065] (a) First, sieve the high-titanium vanadium-titanium ore sintered and returned ore, collect the returned ore with a particle size of less than 1 mm, and then mix the returned ore with a particle size of less than 1 mm and low-quality coal at a mass ratio of 30:70, The mixing of the returned ore with a particle size of less than 1mm and inferior coal is mechanically mixed in a V-shaped mixer, the mixing speed is 30r / min, and the mixing time is 15min to obtain the mixture A;

[0066] (b), adding the mixture A into a mold whose size is (15mm) × (15mm) × (15mm), hot pressing at 400°C and 150kN pressure to obtain the shaped coal material, and then the shaped coal material and The high-quality coal is mixed evenly with a mass ratio of 40:60, and the mixing of the shaped coal material and the high-quality coal is mechanically mix...

Embodiment 3

[0069] A method for preparing iron coke by sintering and returning high-titanium vanadium-titanium ore, said method comprising the following steps:

[0070] (a), first sieve the high-titanium vanadium-titanium ore sintered and returned ore, collect the returned ore with a particle size of less than 1 mm, and then mix the returned ore with a particle size of less than 1 mm and low-quality coal at a mass ratio of 10:90, The mixing of the returned ore with a particle size of less than 1mm and inferior coal is mechanically mixed in a V-shaped mixer, the mixing speed is 20r / min, and the mixing time is 8-15min to obtain the mixture A;

[0071] (b), adding the mixture A into a mold whose size is (10mm) × (10mm) × (10mm), hot pressing at 350°C and a pressure of 140kN to obtain the briquette material, and then the briquette material and The high-quality coal is mixed evenly with a mass ratio of 30:70, and the mixing of the shaped coal material and the high-quality coal is mechanically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com