Mask plate and net extension method and device thereof

A mask and mask technology, applied in the field of masks, can solve the problems of FMM expansion deformation, material inaccurate evaporation, screen color mixing, etc., so as to reduce the difference in deformation, improve accuracy, and reduce screen color mixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

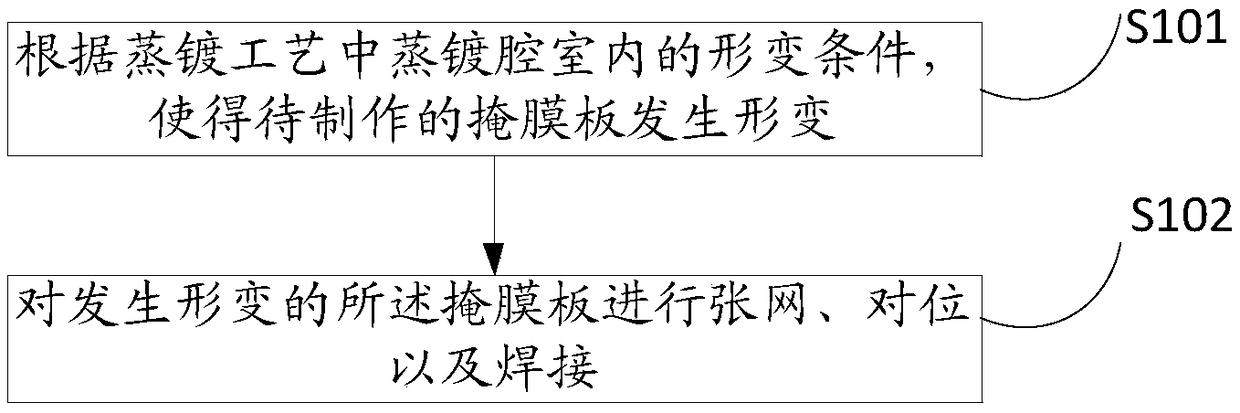

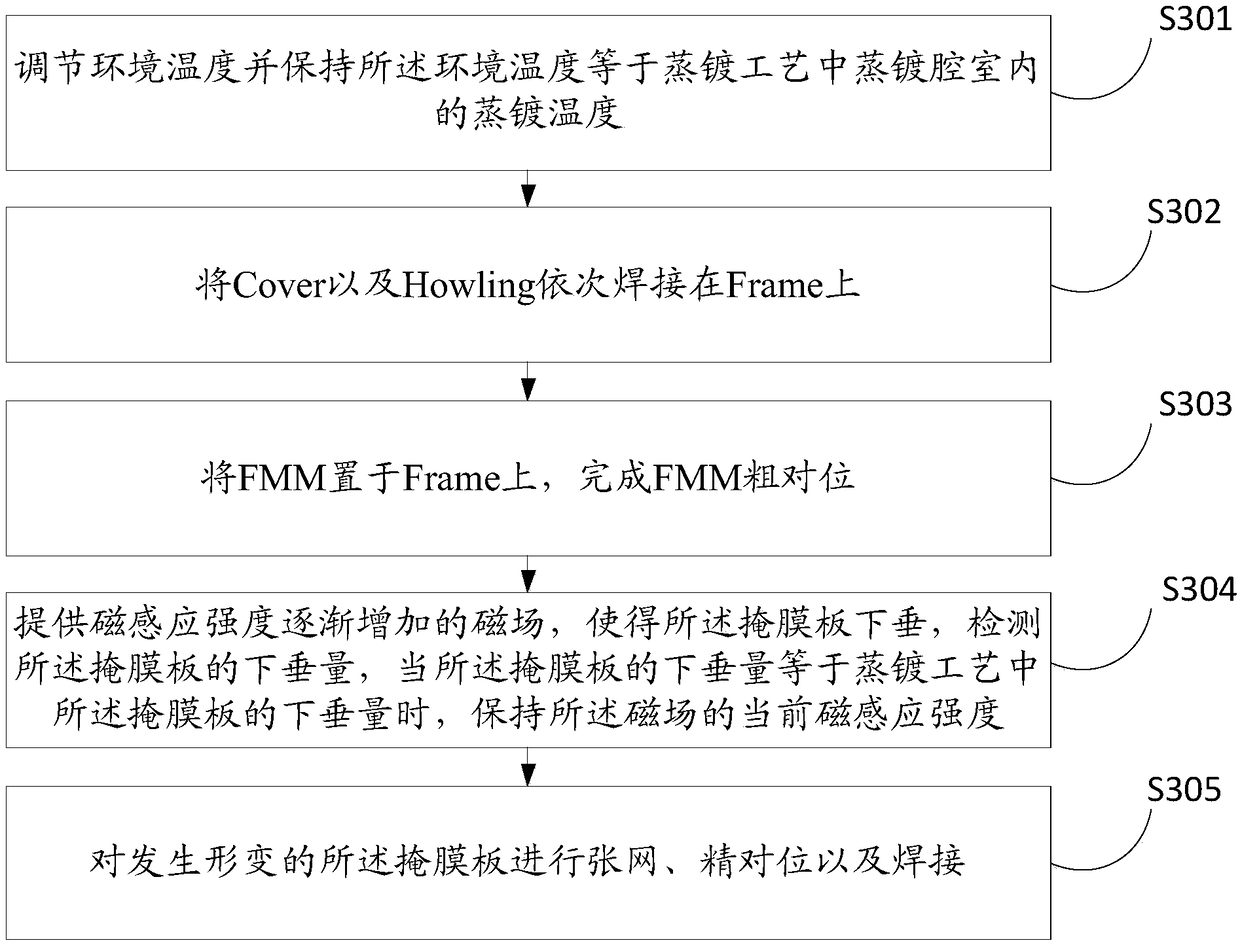

[0031] An embodiment of the application provides a method for spreading a mask, such as figure 1 As shown, the method includes:

[0032] S101: According to the deformation conditions in the vapor deposition chamber in the vapor deposition process, deform the mask to be manufactured;

[0033] S102: Stretching, aligning and welding the deformed mask.

[0034] According to the method for spreading the mask plate provided by the embodiment of the present application, the mask plate to be produced is deformed according to the deformation conditions in the evaporation chamber in the evaporation process, and the mask plate is deformed. Netting, alignment, and welding, mask netting, positioning and welding, consider the factors in the evaporation chamber, so as to reduce the masking board during the welding process and subsequent evaporation process. The difference in the deformation of the film, thereby reducing the difference between the PPA of the mask plate obtained by the screen, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com