Degumming-proof PE protective film glue and preparation method thereof

A protective film and glue technology, applied in the direction of adhesives, pressure-sensitive films/sheets, film/sheet-shaped adhesives, etc., can solve problems such as insufficient viscosity of pressure-sensitive adhesives, weak adhesion, shrinkage of protective molds, etc., to achieve Effects of less warping, increased rigidity and elasticity, and increased cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

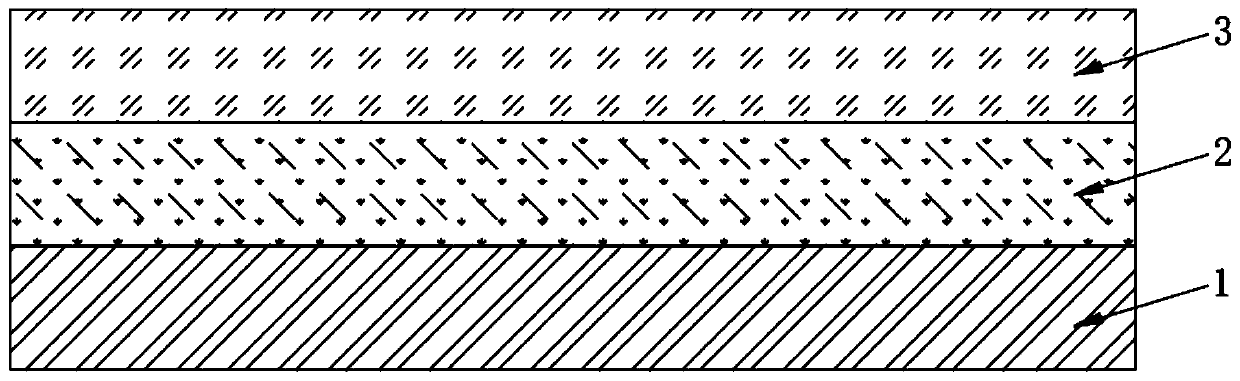

[0022] see figure 1 , the present invention provides the following technical solutions: a kind of anti-degumming PE protective film glue, comprising the following components in units of weight components: 60 parts of propyl acrylate, 15 parts of butyl acrylate, 10 parts of ethyl methacrylate, methacrylic acid 10 parts of butyl ester, 1 part of nonylphenol polyoxyethylene ether, 0.5 part of octylphenol polyoxyethylene ether, 0.3 part of di- and tribenzylphenol polyoxyethylene ether, 180 parts of deionized water, 3 parts of glass fiber, initiator 1.5 parts of agent, 20 parts of tackifier.

[0023] A preparation method of anti-degumming PE protective film glue, comprising the following steps:

[0024] S1. Add 60% of propyl acrylate, butyl acrylate, ethyl methacrylate, butyl methacrylate, initiator and deionized water into the reaction kettle, raise the temperature to 80°C, keep it warm for 30min, and obtain liquid A ;

[0025] S2, all the nonylphenol polyoxyethylene ether, oct...

Embodiment 2

[0034] see figure 1 , the present invention provides the following technical solutions: a kind of anti-degumming PE protective film glue, including the following components in units of weight components: 63 parts of propyl acrylate, 20 parts of butyl acrylate, 14 parts of ethyl methacrylate, methacrylic acid 14 parts of butyl ester, 2 parts of nonylphenol polyoxyethylene ether, 0.75 parts of octylphenol polyoxyethylene ether, 0.5 part of di- and tribenzylphenol polyoxyethylene ether, 195 parts of deionized water, 4 parts of glass fiber, initiator 2 parts of agent, 25 parts of tackifier.

[0035] A preparation method of anti-degumming PE protective film glue, comprising the following steps:

[0036] S1. Add 70% of propyl acrylate, butyl acrylate, ethyl methacrylate, butyl methacrylate, initiator and deionized water into the reaction kettle, raise the temperature to 80°C, keep it warm for 30min, and obtain liquid A ;

[0037] S2, all the nonylphenol polyoxyethylene ethers, oc...

Embodiment 3

[0046] see figure 1 , the present invention provides the following technical solutions: a kind of anti-degumming PE protective film glue, including the following components in units of weight components: 66 parts of propyl acrylate, 25 parts of butyl acrylate, 17 parts of ethyl methacrylate, methacrylic acid 17 parts of butyl ester, 2 parts of nonylphenol polyoxyethylene ether, 0.75 parts of octylphenol polyoxyethylene ether, 0.5 part of di- and tribenzylphenol polyoxyethylene ether, 210 parts of deionized water, 4 parts of glass fiber, initiator 3 parts of agent, 25 parts of tackifier.

[0047] A preparation method of anti-degumming PE protective film glue, comprising the following steps:

[0048] S1. Add 80% of propyl acrylate, butyl acrylate, ethyl methacrylate, butyl methacrylate, initiator and deionized water into the reaction kettle, raise the temperature to 80°C, keep it warm for 30min, and obtain liquid A ;

[0049] S2, all the nonylphenol ethoxylates, octylphenol e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com