Undersea tunnel and construction method thereof

An undersea tunnel and construction method technology, applied in the field of tunnels, can solve the problems of long transportation path, high cost, large energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

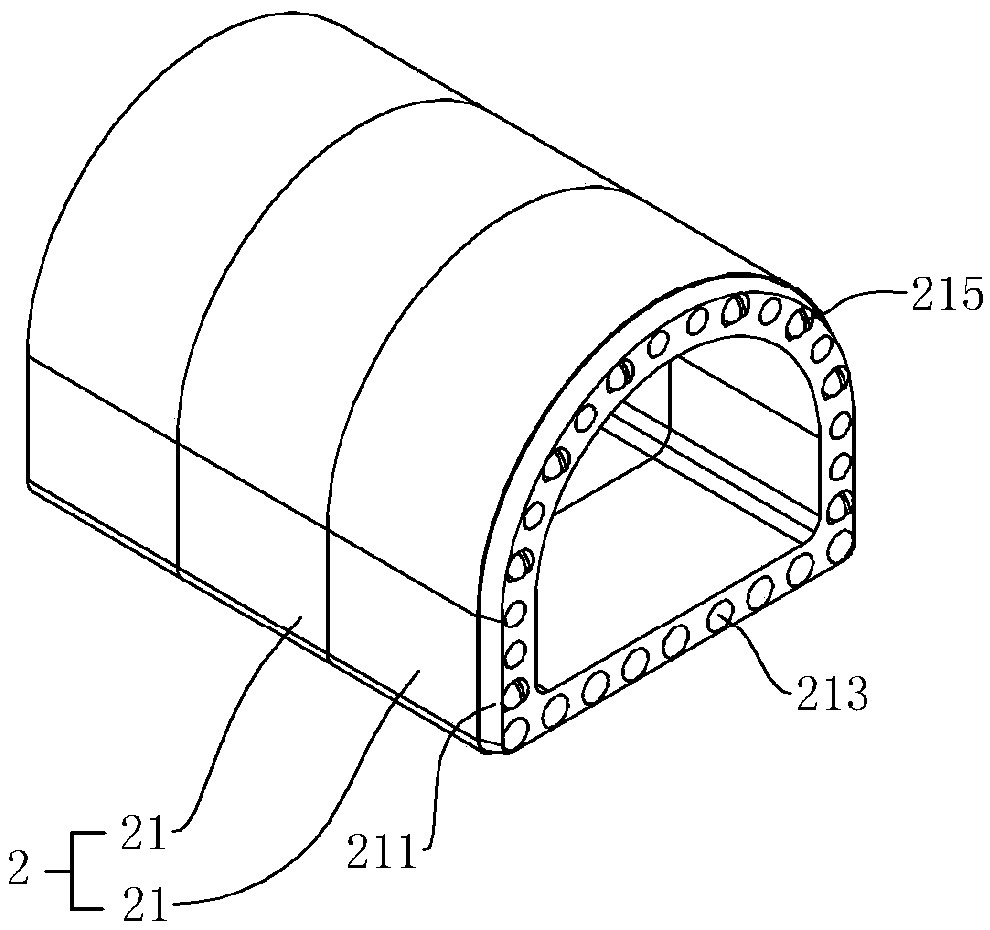

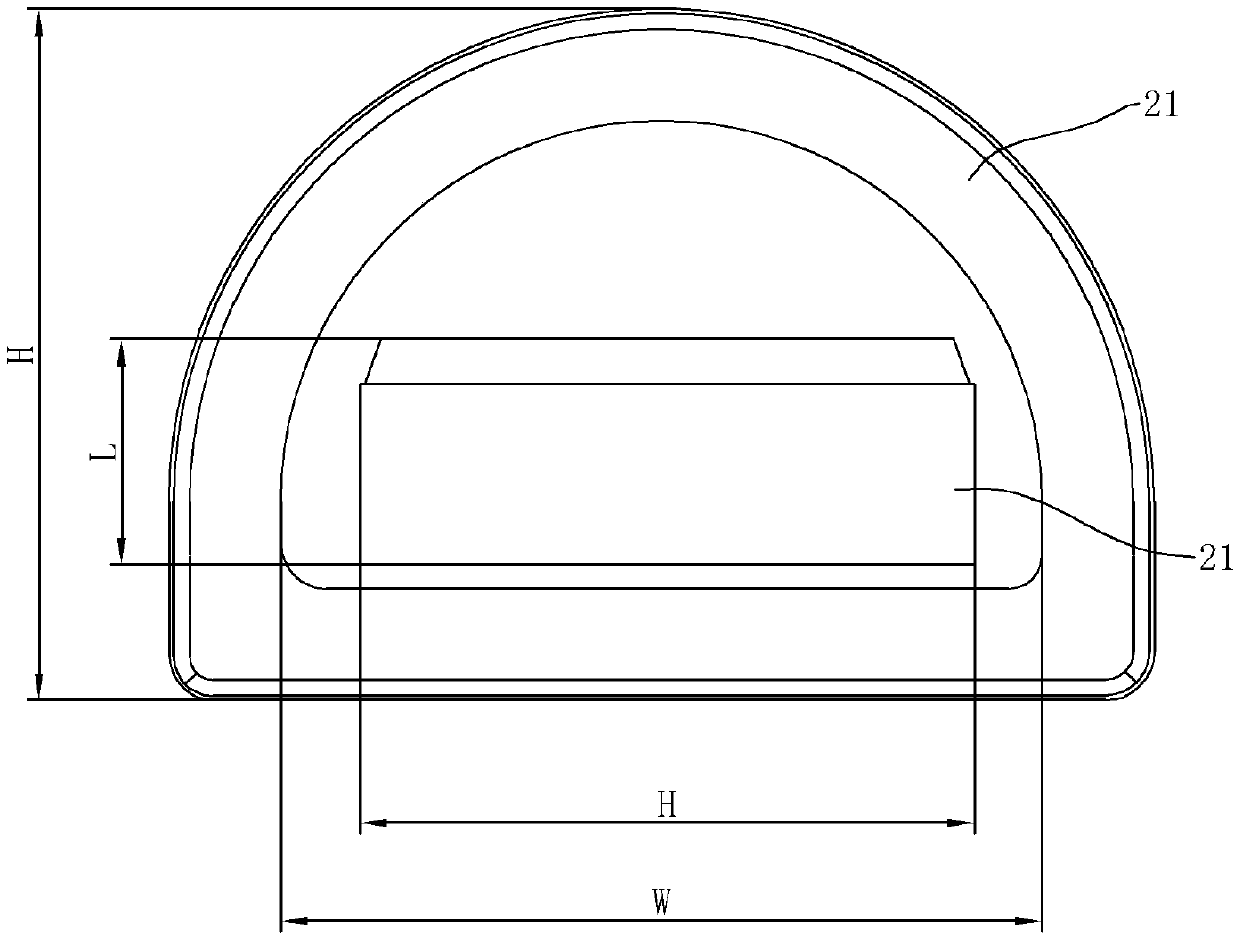

[0054] an undersea tunnel, such as figure 1 As shown, it includes a groove 1 and a lining 2, and the lining 2 is formed by splicing a prefabricated splicing module 21 along the groove 1, and the splicing module 21 is hollow tubular; combined figure 2 The distance between the bottom surface and the top surface on the outside of the splicing module 21 is less than the distance between the two sides on the inside of the splicing module 21. During the splicing process, the splicing module 21 is placed flat and rotated 90 degrees horizontally to the height direction ( figure 2 The size indicated by H in the middle is the height dimension, L refers to the length dimension, and W refers to the width dimension) is parallel to the width direction of the spliced splicing module 21, and then the flat splicing module 21 is spliced from the spliced Module 21 is transported inside.

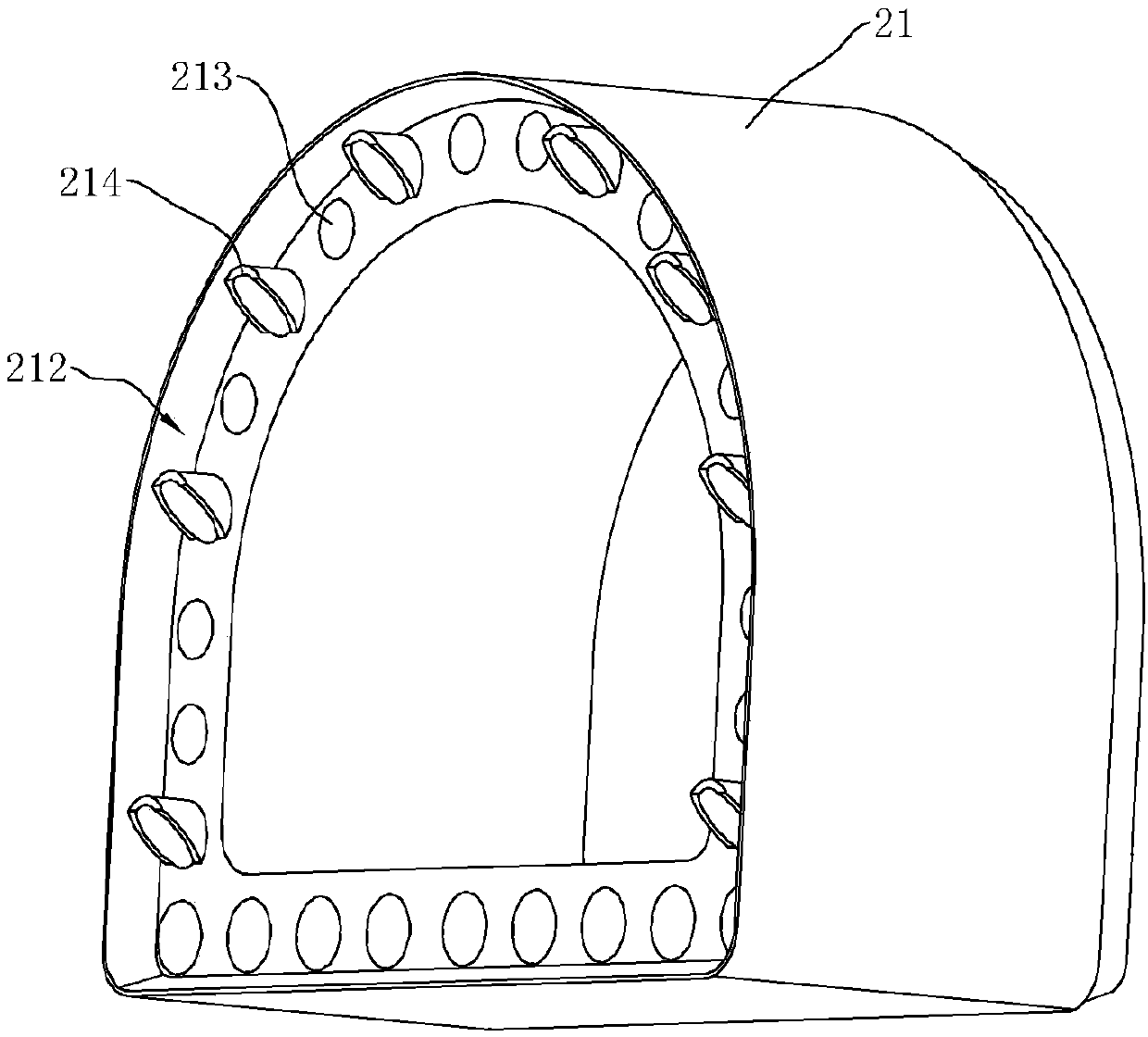

[0055] comprehensive image 3 and Figure 4 One end surface of the splicing module 21 is fixedly co...

Embodiment 2

[0059] A kind of subsea tunnel, the difference from embodiment 1 is, such as Figure 7 As shown, the inner side of the splicing module 21 is horizontally fixedly connected with a horizontal partition 216. The horizontal partition 216 can divide the tunnel into upper and lower spaces, and can be spliced at one time to form two passages, which improves construction efficiency and reduces construction costs. A vertical partition 217 is fixedly connected between the upper surface of the horizontal partition 216 and the inner wall of the splicing module 21. The vertical partition 217 can divide the upper space of the horizontal partition 216 into two parallel spaces. , the air pressure in the space at the front of the train increases, and the space behind the rear of the train forms a sub-vacuum. The high pressure at the front and the low pressure at the rear hinder the advancement of the train. By connecting the two passages above the horizontal partition 216, the two passages W...

Embodiment 3

[0062] A construction method for an undersea tunnel, Figure 8 and Figure 9 (Because the length direction of the drawing is too large, in order to show the structure of the drawing more clearly, the drawing is rotated 90 degrees counterclockwise) It is a schematic diagram of the splicing process of the groove 1 and the splicing module 21, and the construction process The guide machine 3, the dredger (not shown in the figure), the berthing platform 4 and the turning machine 5 need to be used in the middle; The upper surface is provided with an inclined surface, and the inclined surface is inclined towards the bottom surface of the trench 1 along the excavation direction. When the guide machine 3 advances along the trench 1, the residual soil in the trench 1 can be pushed out of the trench 1, and it can also be enlarged. The buoyancy difference of the water that the leading machine 3 top and the bottom are subjected to prevents the leading machine 3 from floating. The tail of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com