Rogowski coil and current measuring device

A Rogowski coil and coil technology, which is applied in the direction of measuring devices, only measuring current, measuring electrical variables, etc., can solve the problems of Rogowski coils with complex structures and susceptibility to environmental interference, so as to reduce interference, uniform winding, and increase induced voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

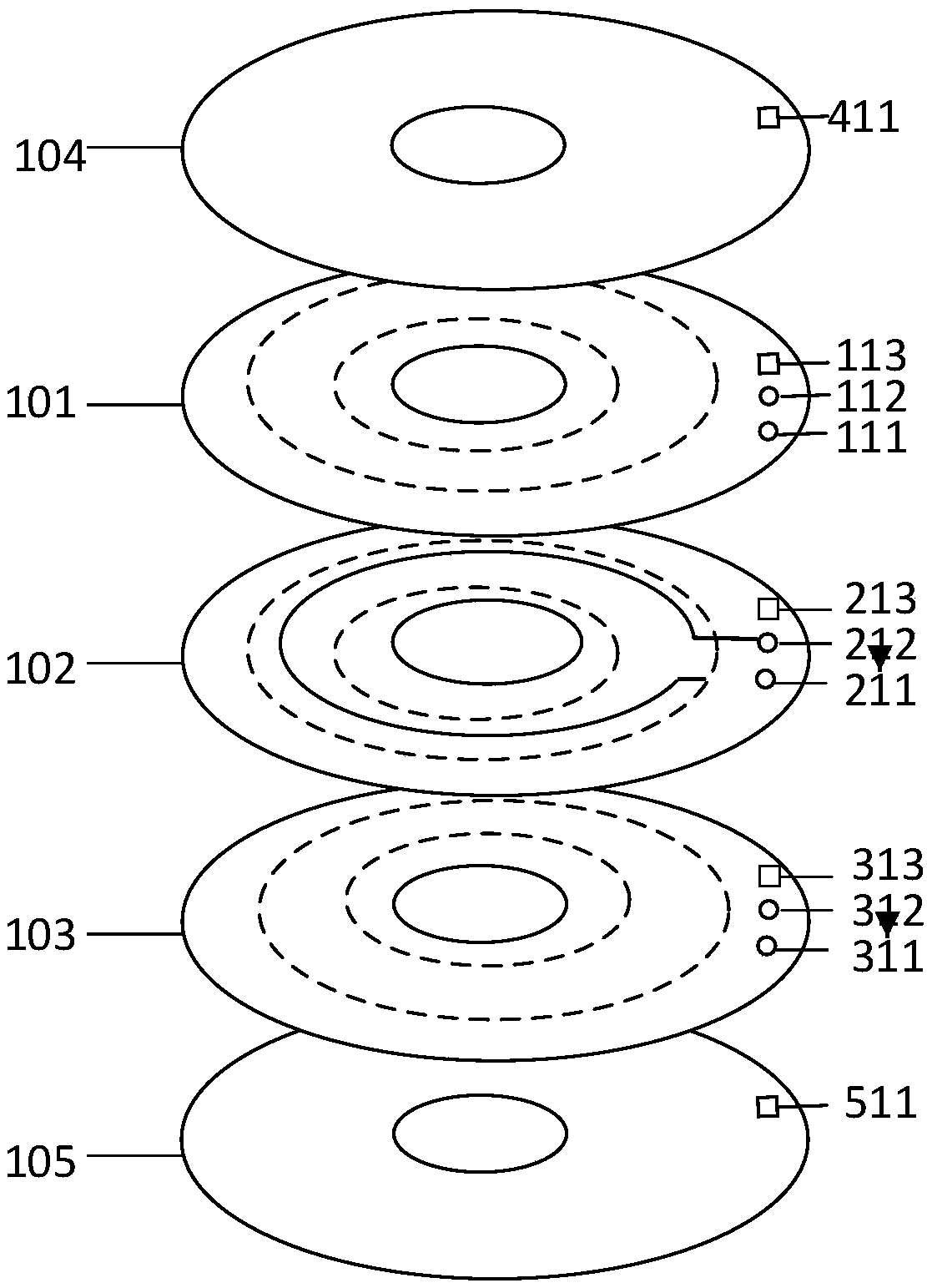

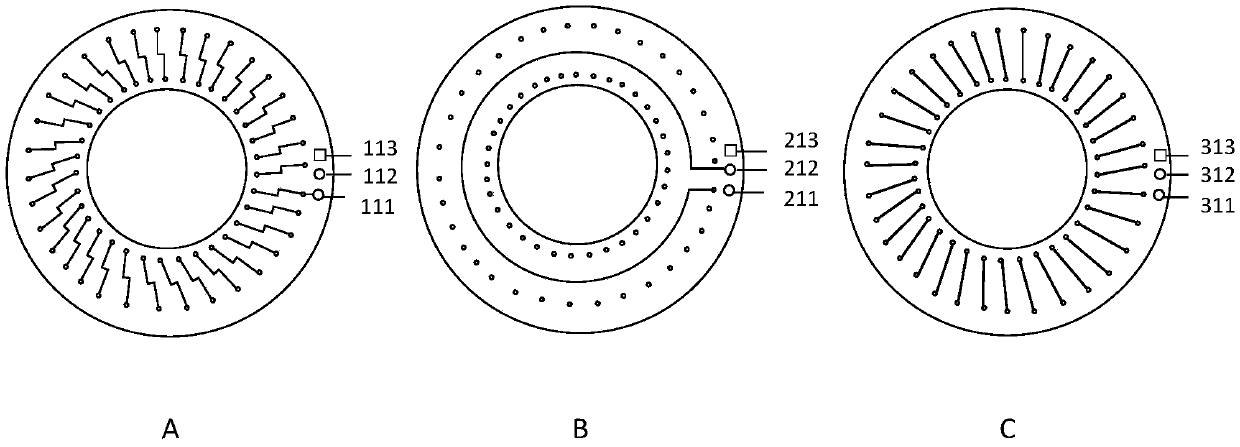

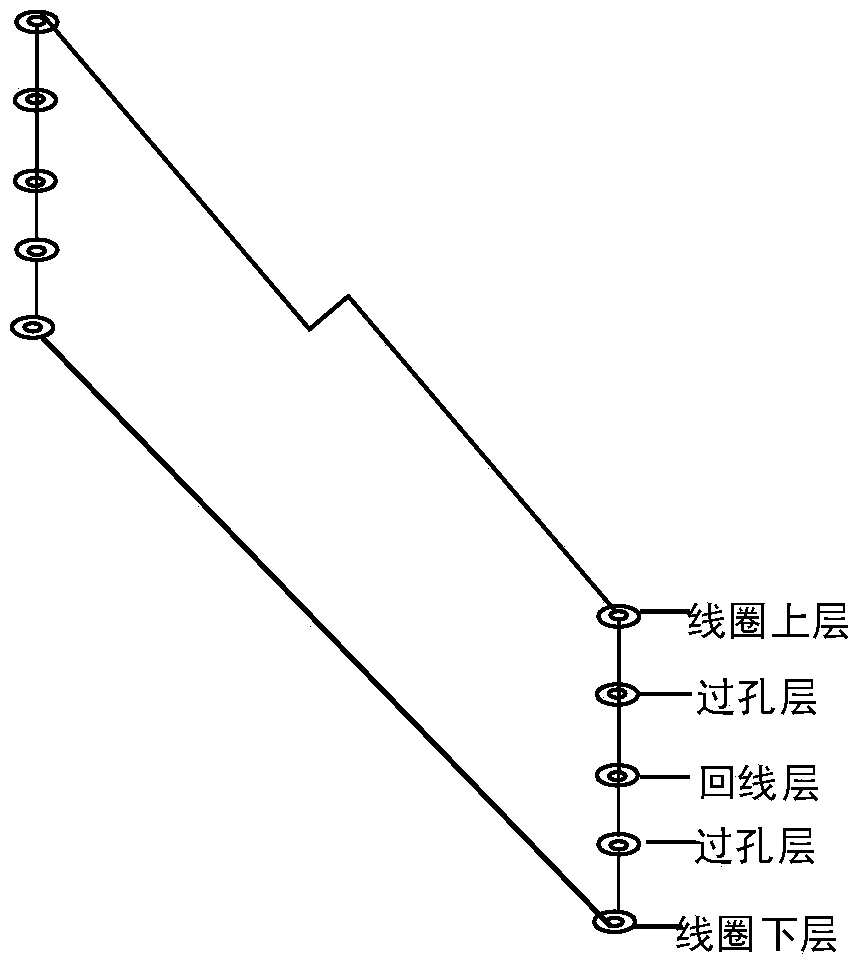

[0032] Such as figure 1As shown, a Rogowski coil in the embodiment of the present invention includes: a coil upper layer 101, including a first PCB board and metal plating, the first PCB board is provided with a plurality of conductive through holes, and the plurality of conductive through holes are uniform Arranged and aligned along the radial direction to form a ring, the conductive through holes of the annular inner ring are obliquely connected to the conductive through holes of the annular outer ring through the metal plating; the loop layer 102 includes the second PCB board and Metal electroplating, the second PCB board is provided with a plurality of conductive through holes, the plurality of conductive through holes are evenly arranged, aligned along the radial direction to form a ring, and the metal electroplating is plated on the second PCB in a circle. On the middle board surface of the annular conductive through hole of the PCB board; the lower layer 103 of the coil...

Embodiment 2

[0045] Based on Example 1, such as Figure 4 As shown, the embodiment of the present invention is a current measuring device, including the Rogowski coil 001 described in the first embodiment. Wherein, it also includes: a signal processing module 002, which is connected with the Rogowski coil 001 through a coaxial measurement cable, and is used for collecting measurement data and calculating waveform parameters of the measurement data.

[0046] In this example, if Figure 5 and Figure 6 As shown, the signal processing module 002 includes: a data acquisition unit 023, which is used to convert the analog signal of the measurement data into a digital signal for easy analysis and calculation; a calculation and analysis unit 024, which is used to calculate the peak value of the waveform of the measurement data and the calculated Describes the time parameter of the waveform of the measurement data.

[0047] As a preferred embodiment, such as Figure 5 As shown, the signal proce...

Embodiment 3

[0053] Such as Figure 7 As shown, in a specific embodiment of the present invention, a current i(t) flows through the measured metal electroplating object, and an induced voltage is generated in the Rogowski coil 11. After the induced voltage is integrated by the integrating circuit, the second circuit through the second PCB board The output hole is output to the coaxial cable, and then the integrated induced voltage is transmitted to the data acquisition unit 41 through the coaxial cable (31, 32, 33). In order to reduce the influence of the external electric field or magnetic field on the induced voltage, a shielding layer 12 is used outside the Rogowski coil 11, and two shielding layers are arranged outside the coaxial cable core wire 31: the outer shielding layer 33 of the cable, the inner shielding layer 32 of the cable, and the outer shielding layer 32 of the cable. The outer shielding layer 33 is connected to the shielding layer 12, and the data acquisition unit shieldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com