Overhead line integrated tester

A comprehensive test and overhead line technology, applied in the direction of instruments, measuring devices, measuring electricity, etc., can solve the problems of cumbersome inconvenience, poor accuracy, low efficiency, etc., and achieve the effect of improving work efficiency, simplifying the structure of the instrument, and simplifying the test process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

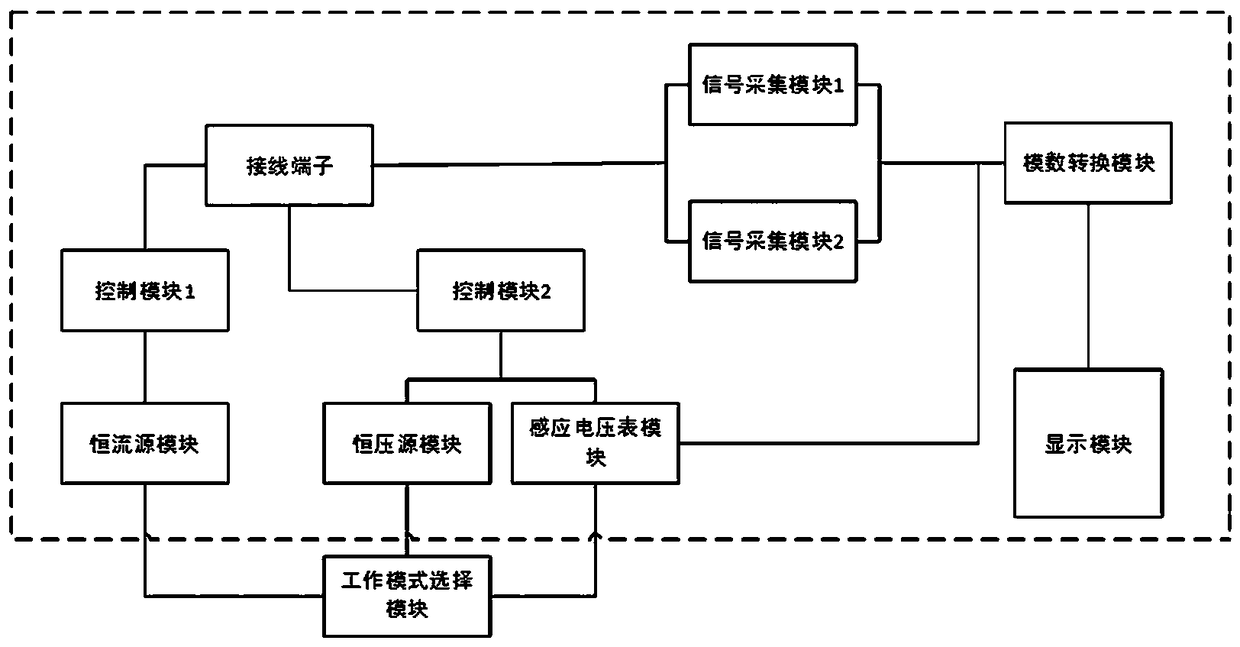

[0023] Such as figure 1 As shown, the overhead line comprehensive tester includes a working mode selection module, a constant current source module, a constant voltage source module, an induction voltmeter module, a control module 1, a control module 2, terminal blocks, a signal acquisition module 1, and a signal acquisition module 2 , an analog-to-digital conversion module and a display module, the working mode selection module is connected to the constant current source module, the constant voltage source module, and the induction voltmeter module; the constant current source module is connected to the control module 1, and the constant voltage source module, the induction voltmeter module is connected to the The control module 2 is connected; the control module 1 and the control module 2 are connected to the terminal, and the terminal is connected to the signal acquisition module 1 and the signal acquisition module 2; the signal acquisition module 1 and the signal acquisitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com