A method for scheduling production plan in a tire manufacture enterprise

A technology for production planning and tires, applied in the direction of manufacturing computing systems, calculations, instruments, etc., can solve problems such as the inability to comprehensively balance process parameters, and achieve the effect of convenient upgrade and maintenance, many processes, and many varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

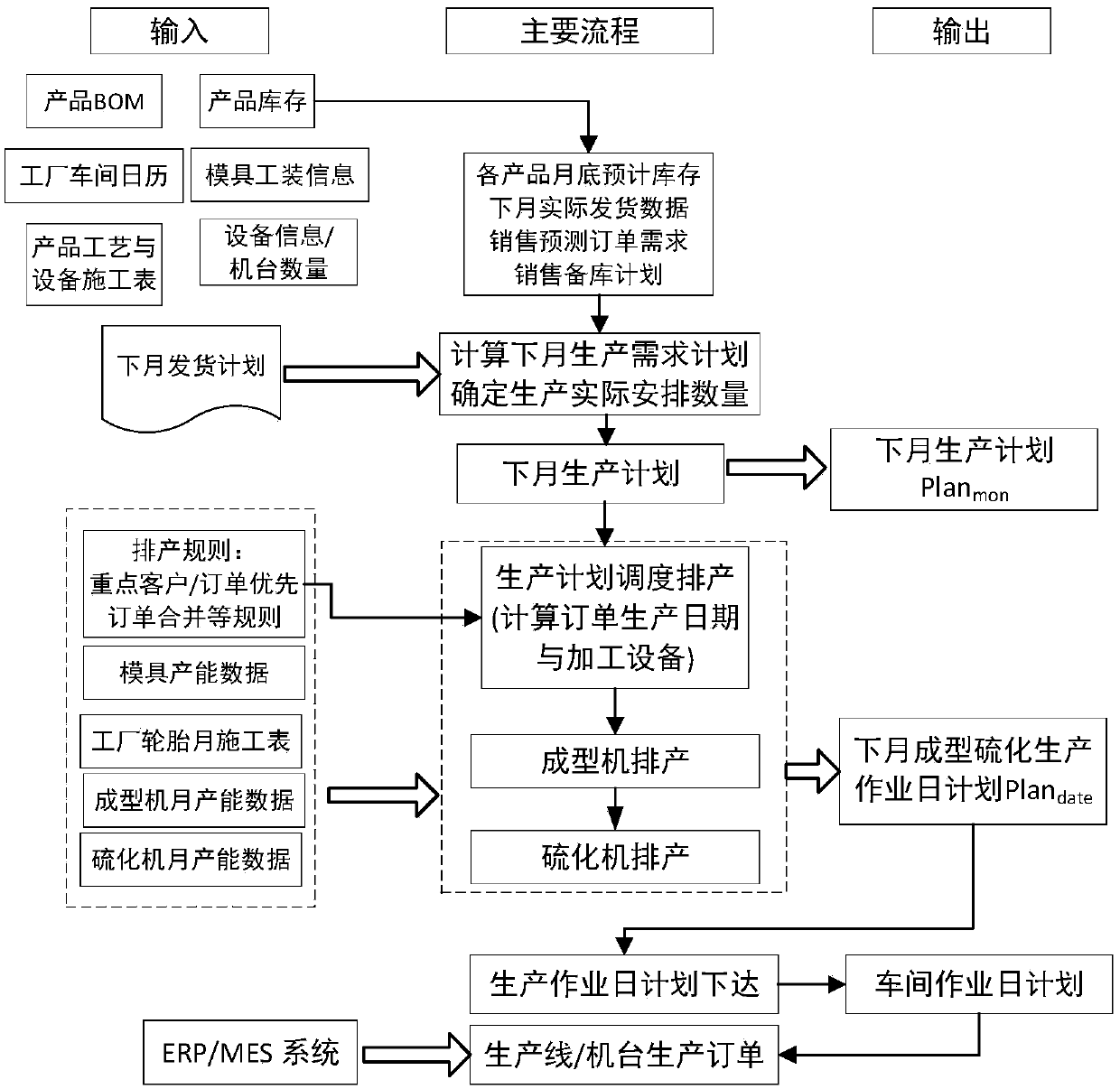

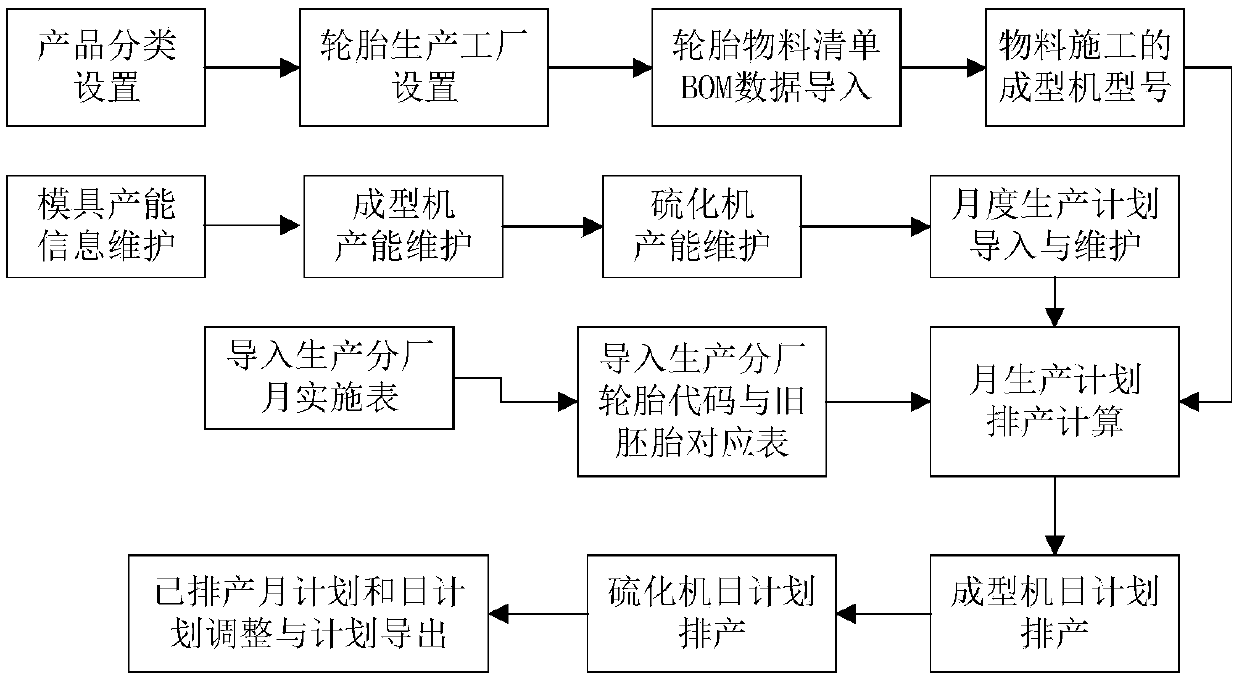

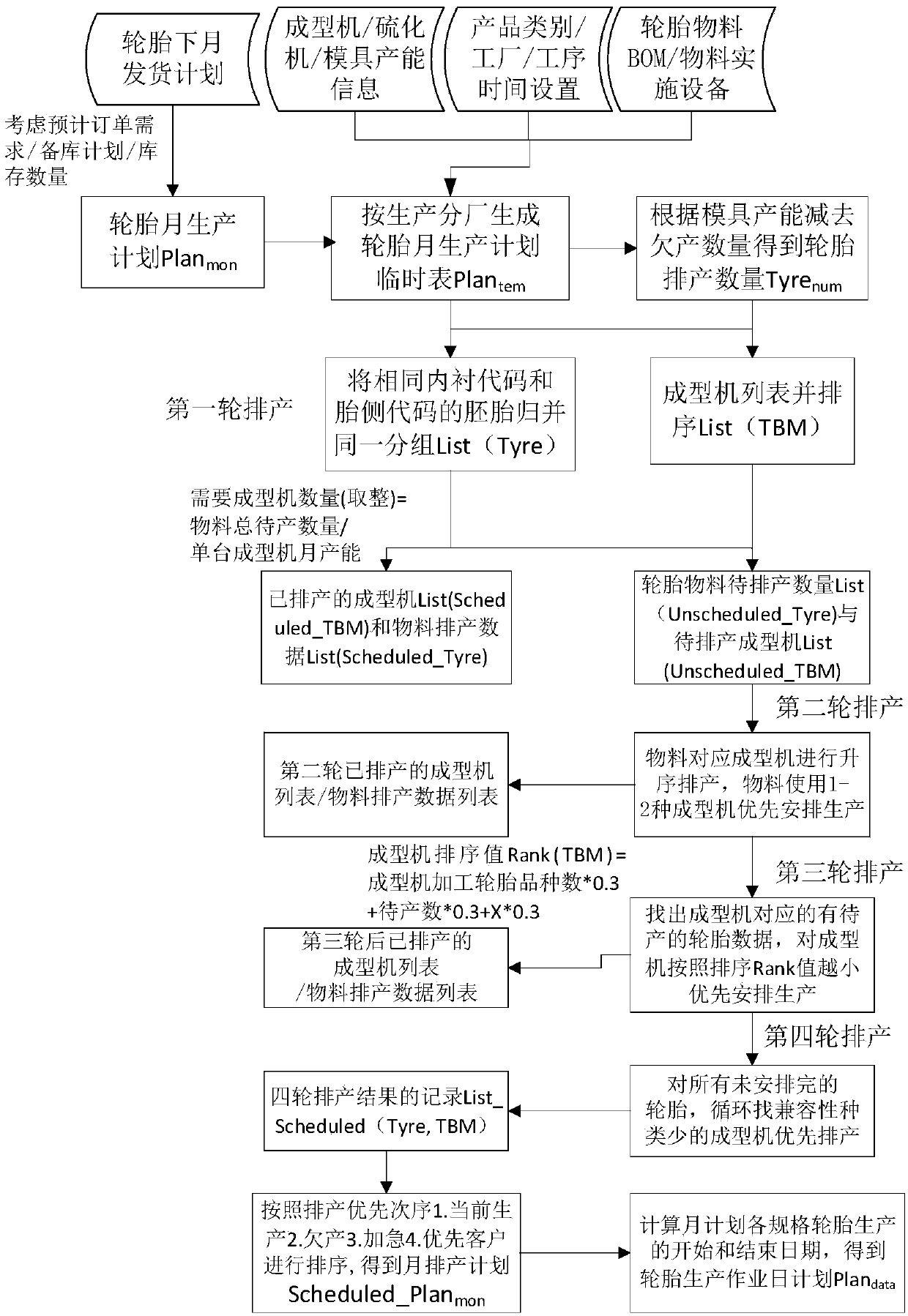

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the examples.

[0049] (1) Set basic data.

[0050] The basic data of the system comes from the enterprise MES system and ERP system data, set the factory calendar and shift information maintenance, and set the tire product category (serial number, tire category, description). Set the production branch information (serial number, production branch name, production tire category description). Import tire material information from MES system, including tire material code, tire name, specification and size. Import the construction equipment information of tire materials, including tire material codes, inch sizes, and building machine models. Import mold capacity balance table information from MES system or Excel file, including mold number, mold quantity, daily production capacity of one mold, and total daily production capacity field data. Import molding machine and vulcanizing machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com