Ultra-stable silver-tantalum composite material surface-enhanced Raman scattering substrate and preparation method

A surface-enhanced Raman, composite material technology, applied in metal material coating process, sputtering coating, vacuum evaporation coating and other directions, can solve the limitation of adsorption, separation, catalysis, sensing, inconvenient mass preparation, preparation process complex problems, to achieve the effects of good chemical stability, good surface plasma performance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

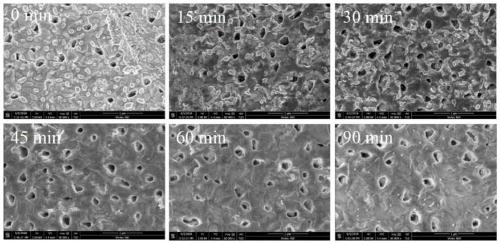

[0039] The invention provides a method for preparing a silver-tantalum composite SERS substrate material, comprising the following steps:

[0040] 1) Single crystal silicon wafer is selected as the substrate, and the single crystal silicon wafer substrate is selected from Si(100), Si(111), SiO 2 sheet or quartz glass. And perform pretreatment before coating; specifically, use deionized water, absolute ethanol, and acetone to ultrasonically clean the surface of the single crystal silicon wafer for 10-20 minutes.

[0041] 2) Put the cleaned single crystal silicon substrate into the magnetron sputtering coating equipment to prepare the chromium primer layer, specifically using Ar gas or nitrogen as the sputtering atmosphere, under the condition of applying a voltage of 60V to the substrate, using Magnetron sputtering is performed on the chromium target by radio frequency, and the radio frequency frequency is controlled at 250kHz; a layer of chromium film with a thickness of 100-...

Embodiment 1

[0047] 1) Cleaning: immerse the Si(100) substrate in ethanol and acetone solution for 10 minutes, take it out and soak it in deionized water for 10 minutes, then take it out, dry it with high-purity nitrogen, and then quickly put it into the magnetron sputtering coating equipment .

[0048] 2) Chromium primer preparation: prepare a chromium primer on the surface of the cleaned Si(100) substrate, use Ar gas as the sputtering atmosphere, apply a voltage of 60V, and use radio frequency to perform magnetron sputtering on the chromium target with a radio frequency of 250kHz; The thickness of the chromium film is 100nm.

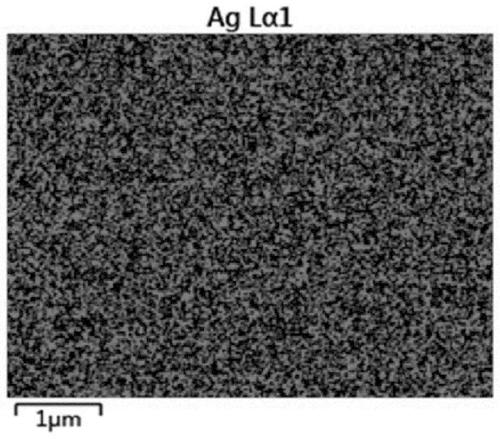

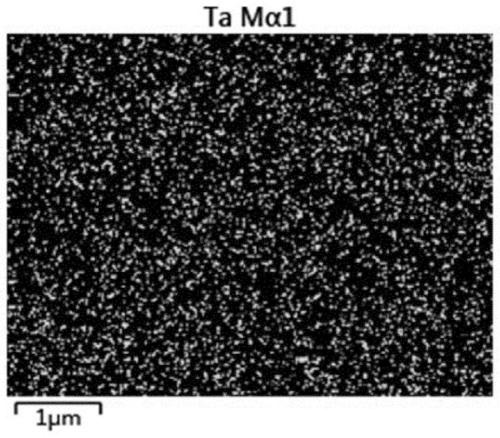

[0049] 3) Silver and tantalum deposition: After the preparation of the chromium base layer, co-sputtering of silver and tantalum elements is carried out, in which the applied voltage is 60V, the current of the silver target is 5A, the current of the tantalum target is 2A, and the deposition time is 30min. The thickness of silver and tantalum composite film deposit...

Embodiment 2

[0061] 1) Cleaning: immerse the Si(111) substrate in ethanol and acetone solution for 10 minutes, take it out and soak it in deionized water for 15 minutes, then take it out, dry it with high-purity nitrogen, and then quickly put it into the magnetron sputtering coating equipment .

[0062] 2) Chromium primer preparation: prepare chromium primer on the clean single crystal silicon surface, use nitrogen as the sputtering atmosphere, apply 60V voltage, and use radio frequency to perform magnetron sputtering on the chromium target with a radio frequency frequency of 250kHz; the thickness of the chromium film 500nm.

[0063] 3) Silver and tantalum deposition: After the preparation of the chromium base layer, co-sputtering of silver and tantalum elements is carried out, in which the applied voltage is 60V, the current of the silver target is 5A, the current of the tantalum target is 5A, and the deposition time is 15min. The thickness of silver and tantalum composite film deposited...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com