Ultraviolet sterilization device and washing machine

A technology for sterilizing devices and washing machines, which is applied to other washing machines, washing devices, cleaning hollow objects, etc., and can solve the problems of weakening sterilizing effect, affecting the penetration effect of ultraviolet light, and interlayers that cannot be cleaned directly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

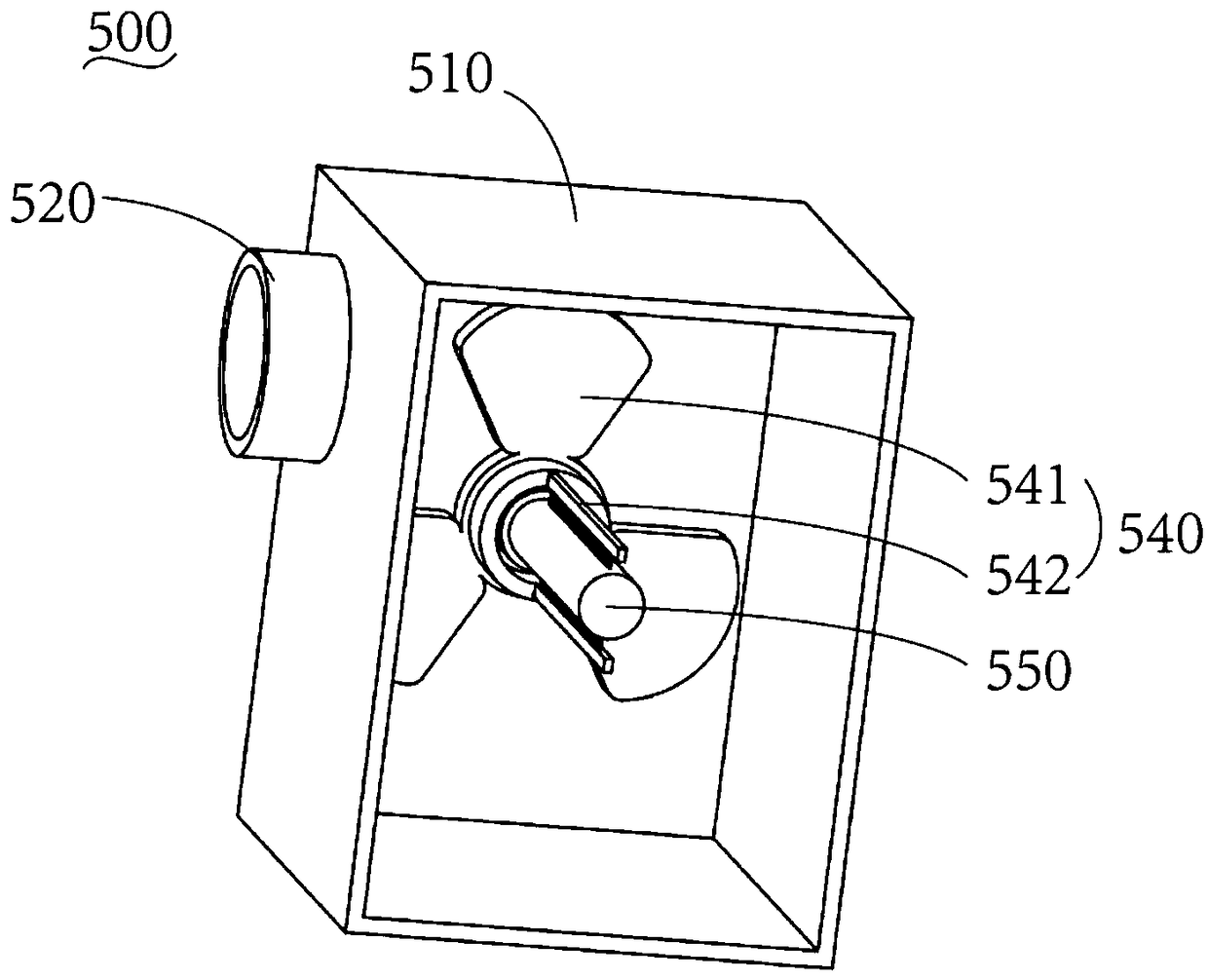

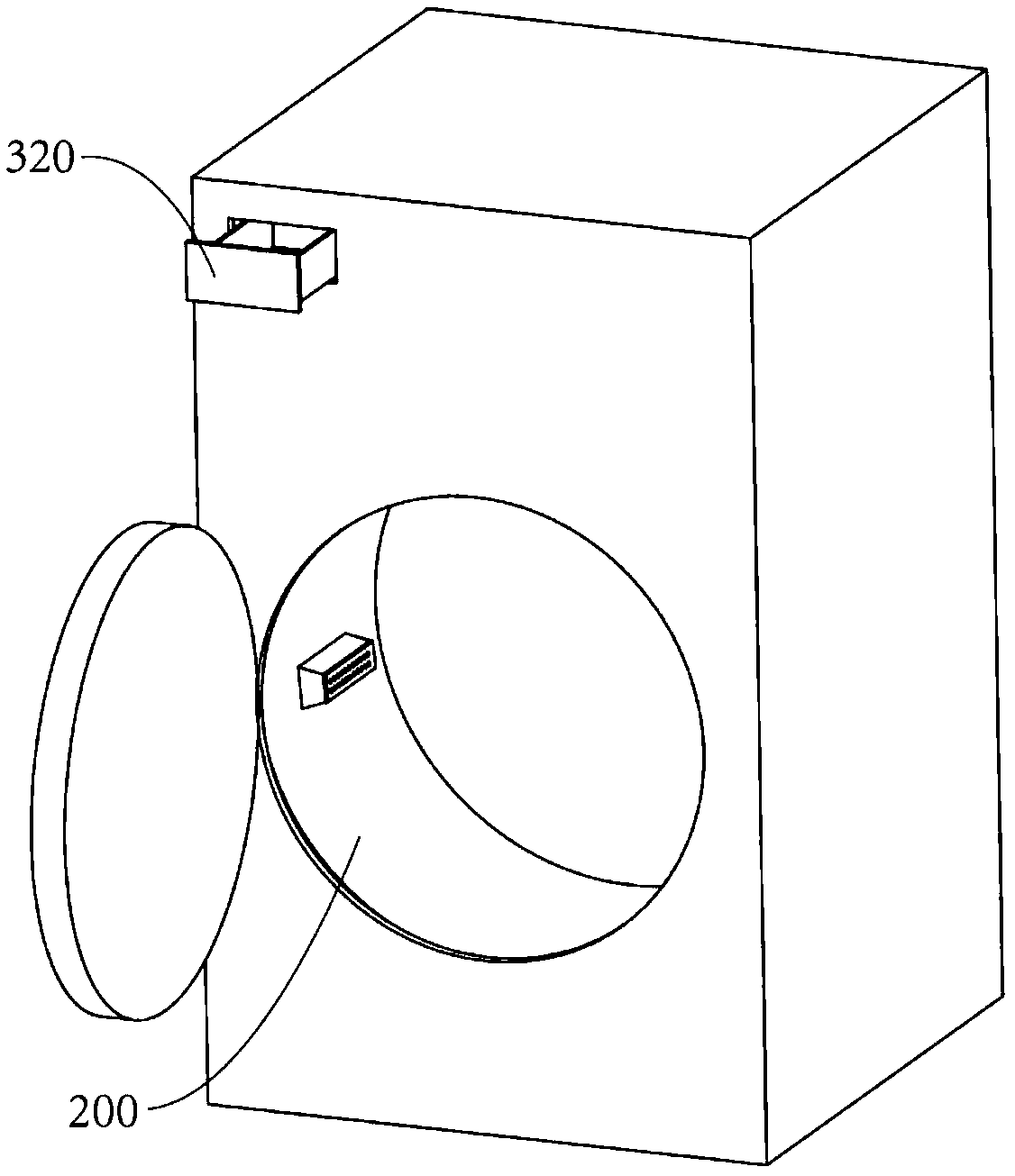

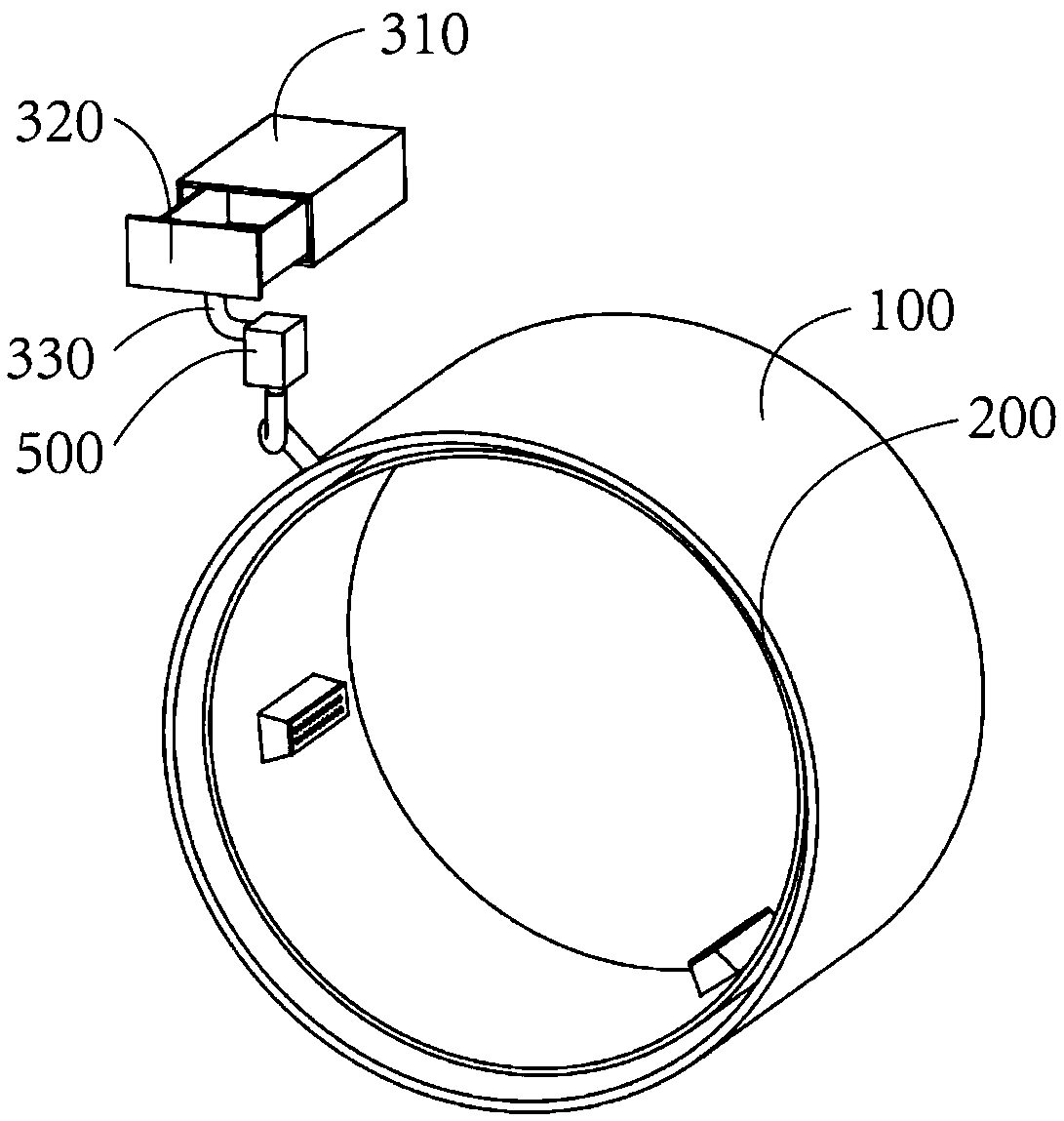

[0034] like image 3 and Figure 4 As shown, the washing machine includes a detergent box 320 communicating with a water injection tank 310 , and the washing box communicates with the outer tub 100 of the washing machine through a water injection pipeline 330 . The ultraviolet sterilizing device 500 is arranged on the water injection pipeline 330 .

[0035] When it is necessary to wash clothes, the washing water enters the cavity through the water injection tank 310, the detergent box 320, the water injection pipeline 330, and the water inlet 520 of the ultraviolet sterilizing device 500; the water flow entering from the water inlet 520 pushes the impeller 541 rotates 360°, so that the cleaning brush 542 rotates 360° with the washing water flow, and the water sterilized by ultraviolet rays flows into the outer tub 100 and the inner tub 200 of the drum washing machine through the water outlet 530 and the water injection pipeline 330 to wash the clothes.

Embodiment 2

[0037] like Figure 5 As shown, the washing machine includes a spraying device. The spraying device includes a spraying port 410, a water circulation pipeline 420 and a water pump 430 arranged on the water circulation pipeline 420. One end of the water circulation pipeline 420 communicates with the bottom of the outer tub 100 of the washing machine, and the other end is set Spray outlet 410 . The spray outlet 410 is disposed above the outer tub 100 of the washing machine. The ultraviolet sterilizing device 500 is arranged on the water circulation pipeline 420 .

[0038] When washing clothes, the water pump 430 below the outer tub 100 pumps up the washing water in the outer tub 100, and enters the ultraviolet sterilizing device 500 for ultraviolet light sterilization. Perform a wash.

[0039] The above-mentioned ultraviolet sterilizing device 500 can be installed on the water injection pipeline 330 and the water circulation pipeline 420 at the same time, so as to improve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com