Electric oil pump assembly, steering system and lubricating system

An electric oil pump and assembly technology, which is applied in the field of lubrication systems, can solve the problems of large volume of electric oil pumps, complex structure of damping elements, high noise of motor operation, etc., achieve high level of light weight, improve heat dissipation performance and work stability , the effect of high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

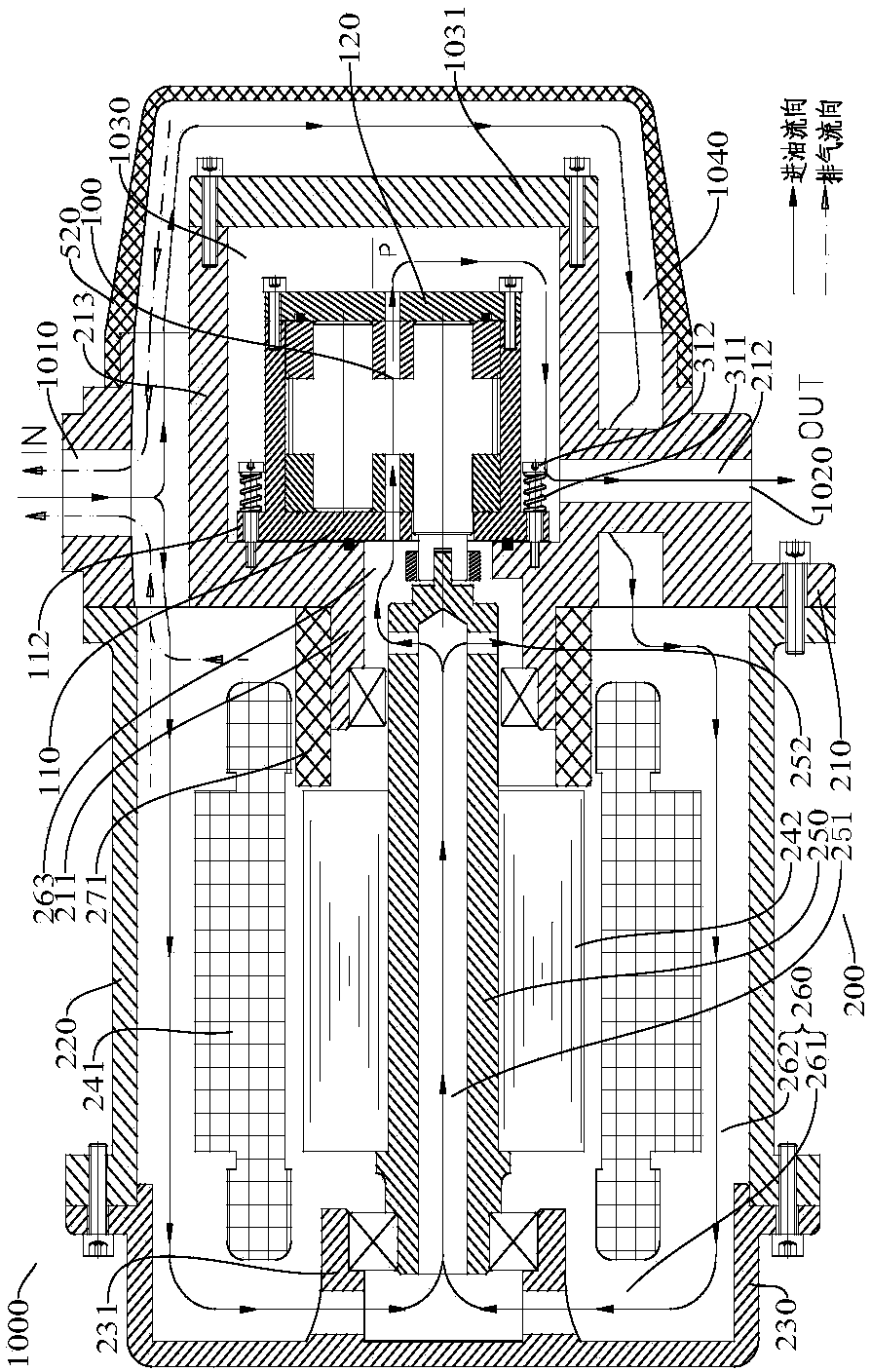

[0061] Such as figure 1 , Figure 4 , Figure 5 , Figure 10 , Figure 13 , Figure 14 , Figure 19 , Figure 21 , Figure 22 , Figure 24 , Figure 26 , Figure 27 , Figure 29 , Figure 31 , Figure 32 , Figure 34 , Figure 36 , Figure 37 , Figure 39 As shown, an electric oil pump assembly 1000 according to an embodiment of the present invention includes: a motor assembly 200 and an oil pump assembly 100 .

[0062] Wherein, the oil pump assembly 100 is dynamically coupled with the motor shaft 250, and the motor assembly 200 is used to provide the driving force for the operation of the oil pump assembly 100. For example, the motor shaft 250 of the motor assembly 200 can be connected with the oil pump shaft 130 of the oil pump assembly 100 through a coupling 410. Of course, the motor assembly 200 is not limited to directly driving the oil pump assembly 100 , and can also be connected to the oil pump assembly 100 through a transmission mechanism such as a g...

Embodiment 2

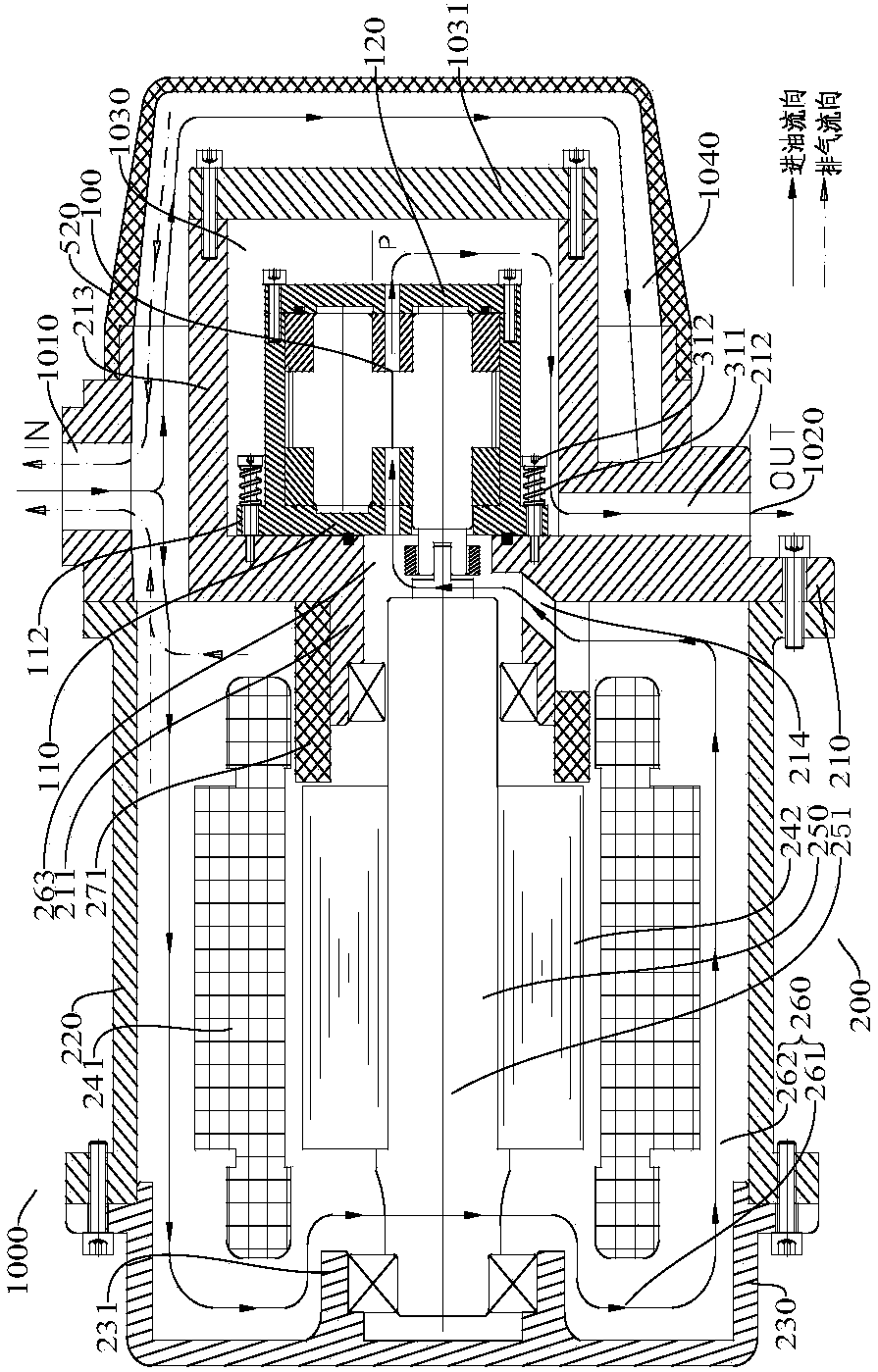

[0084] Such as figure 2 , Figure 6 , Figure 7 , Figure 11 , Figure 15 , Figure 16 , Figure 20 , Figure 23 , Figure 25 , Figure 28 , Figure 30 , Figure 33 , Figure 35 , Figure 38 , Figure 40 As shown, an electric oil pump assembly 1000 according to an embodiment of the present invention includes: a motor assembly 200 and an oil pump assembly 100 .

[0085] Wherein, the oil pump assembly 100 is dynamically coupled with the motor shaft 250, and the motor assembly 200 is used to provide the driving force for the operation of the oil pump assembly 100. For example, the motor shaft 250 of the motor assembly 200 can be connected with the oil pump shaft 130 of the oil pump assembly 100 through a coupling 410. Of course, the motor assembly 200 is not limited to directly driving the oil pump assembly 100 , and can also be connected to the oil pump assembly 100 through a transmission mechanism such as a gearbox or a reducer.

[0086] The oil pump assembly 100...

Embodiment 3

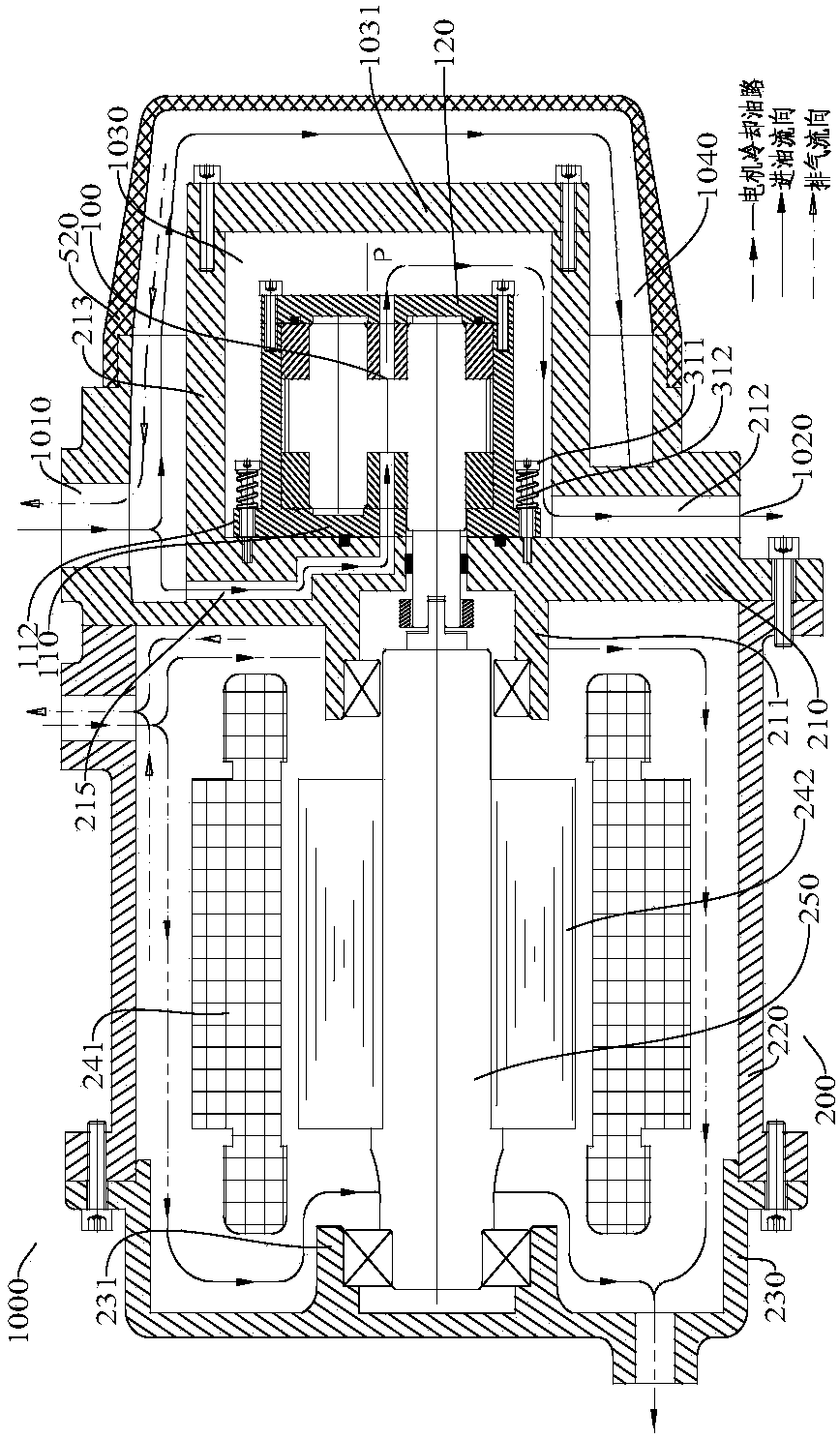

[0105] Such as image 3 , Figure 8 , Figure 9 , Figure 12 , Figure 17 , Figure 18 As shown, an electric oil pump assembly 1000 according to an embodiment of the present invention includes: a motor assembly 200 and an oil pump assembly 100 .

[0106] Wherein, the oil pump assembly 100 is dynamically coupled with the motor shaft 250, and the motor assembly 200 is used to provide the driving force for the operation of the oil pump assembly 100. For example, the motor shaft 250 of the motor assembly 200 can be connected with the oil pump shaft 130 of the oil pump assembly 100 through a coupling 410. Of course, the motor assembly 200 is not limited to directly driving the oil pump assembly 100 , and can also be connected to the oil pump assembly 100 through a transmission mechanism such as a gearbox or a reducer.

[0107] The oil pump assembly 100 works under the drive of the motor assembly 200 to convert the low-pressure oil into high-pressure oil output. The oil pump as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com