Gasifying station with plunger pump

A plunger pump and gasification station technology, applied in the field of gasification stations with plunger pumps, can solve the problem that natural gas cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

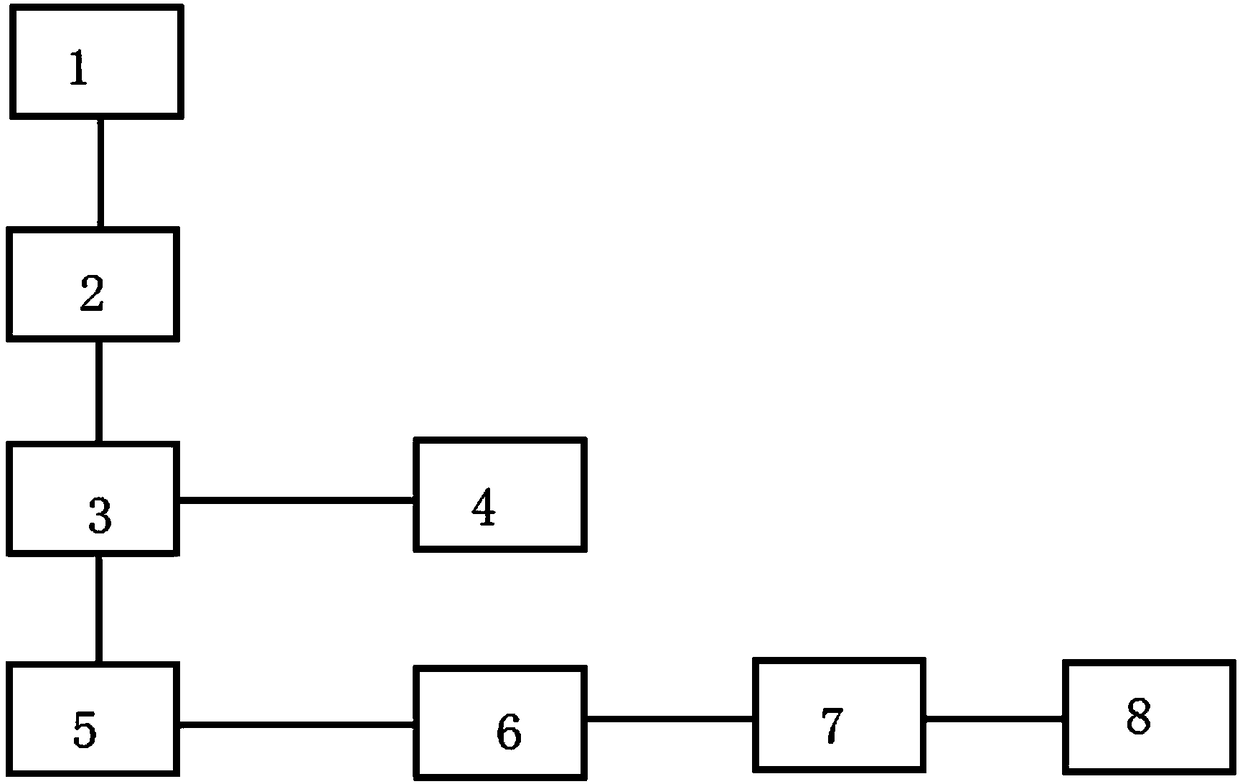

[0017] Such as figure 1 As shown, a gasification station with a plunger pump includes an LNG tanker 1, an LNG storage tank 3, an air-temperature vaporizer 6, a pressure regulating metering and odorizing skid 8, an LNG tanker 1 and an LNG storage tank The pressure of 3 is balanced by the unloading booster skid 2, which increases the pressure in the LNG tanker 1, and the LNG is transported to the LNG storage tank 3 for storage. The LNG storage tank 3 is equipped with a storage tank booster 4. 3 When draining outside, first pressurize the LNG storage tank 3 through the tank booster 4 of the LNG storage tank 3 to increase the pressure of the LNG storage tank 3, and then open the liquid phase outlet valve of the LNG storage tank 3 to push the inside of the LNG storage tank 3 through the pressure difference. After the LNG is sent to the air-heated vaporizer 6, it is sent to the municipal gas pipeline network or gas boiler through the pressure regulating metering and odorizing skid 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com