Testing structure and method for engine timing system dynamic performance

A technology of dynamic performance and timing system, which is applied in the field of timing belt or chain device, which can solve problems such as easy cracking and short service life, and achieve the effects of reducing wear elongation, reducing noise and improving fuel consumption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

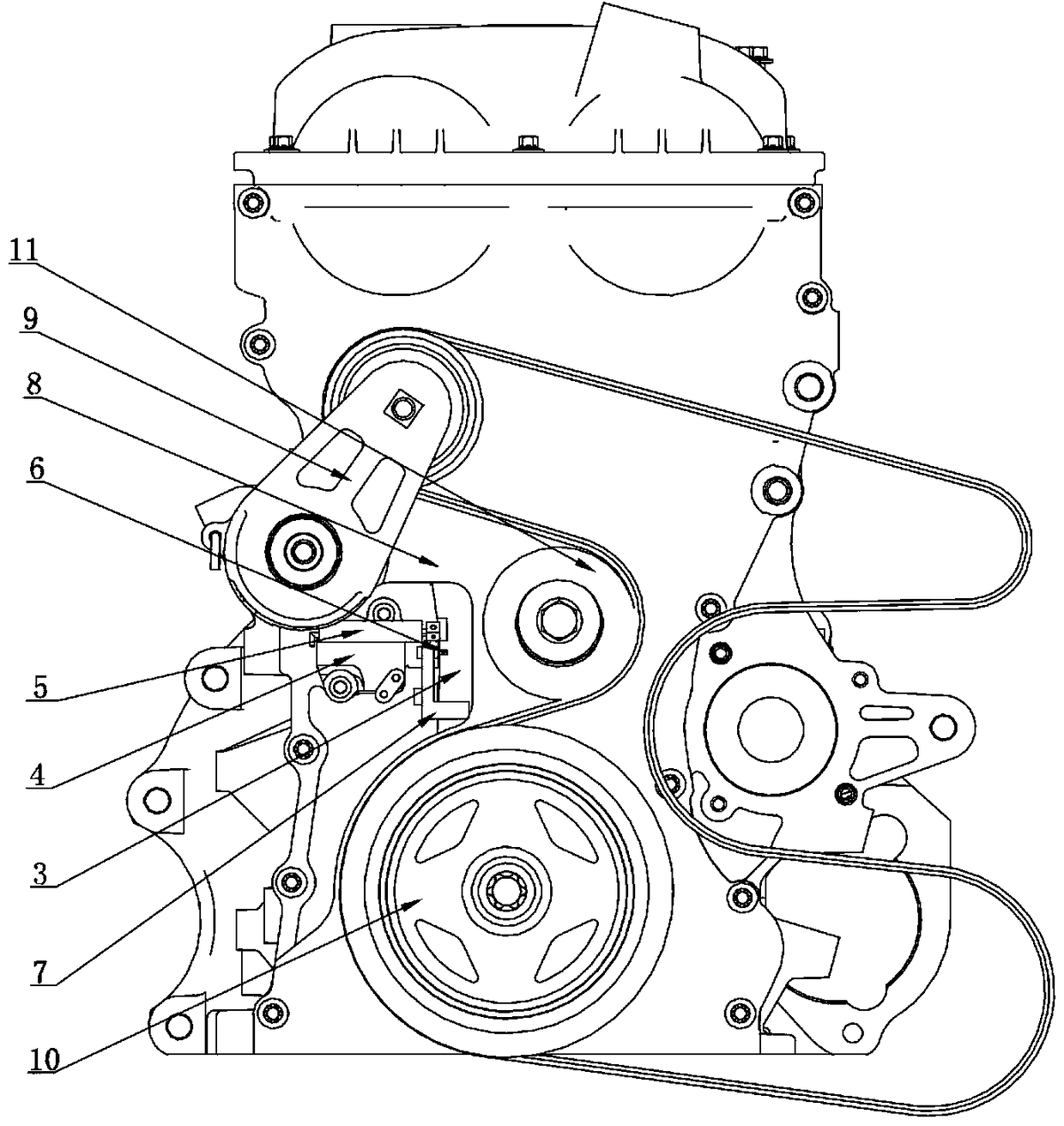

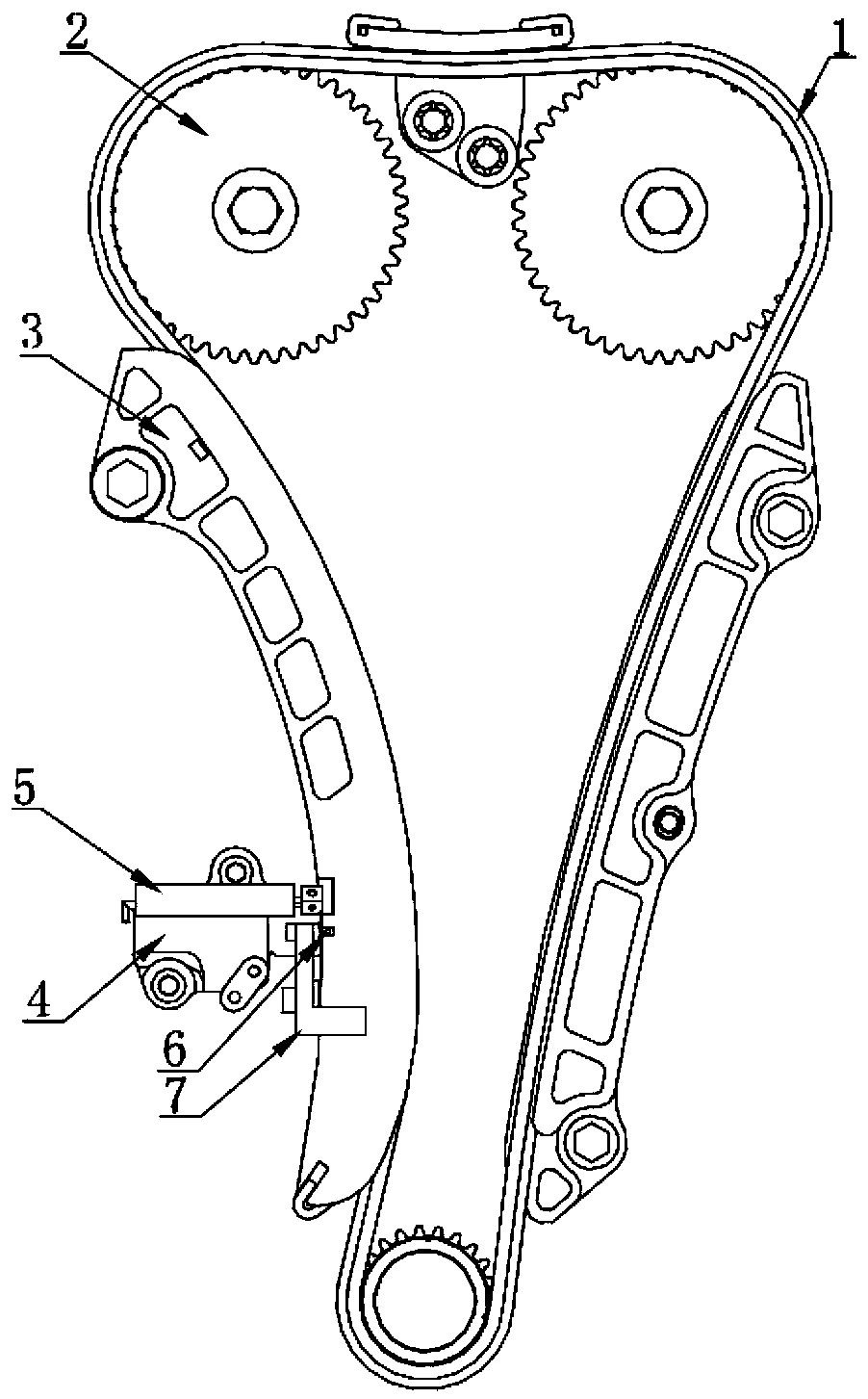

[0011] Such as Figure 1-3 As shown, the chain 1 includes two states, the first is the original factory state chain, and the second is the elongation rate of 0.7% state chain. Its purpose is to measure the stability of the timing system at the initial state and the timing system at the design life state.

[0012] The sprocket 2 is an important part of the timing system, and the test sprocket does not need to be subjected to any tooth profile heat treatment, which reduces the test cost.

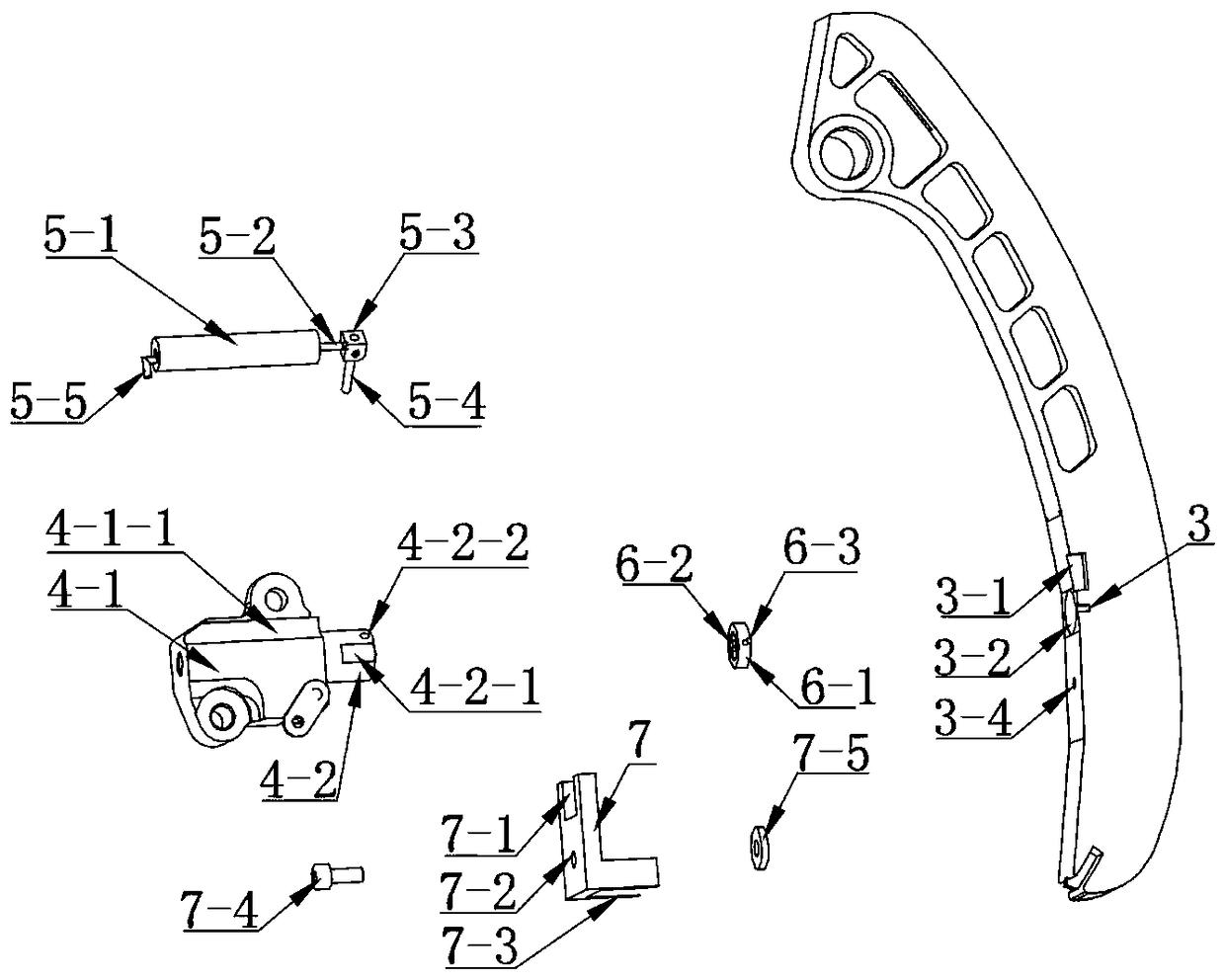

[0013] The restructured moving guide rail 3 is mainly fixed by a displacement sensor magnetic bar to avoid a pit 3-1 for an adapter block, a pressure sensor installation pit 3-2, a pressure sensor wire avoidance hole 3-3, and a tensioner plunger radial limit The block mounting bolt hole is composed of 3-4 structures.

[0014] The restructured tensioner 4 is mainly composed of a restructured tensioner housing 4-1, a restructured tensioner plunger 4-2, a tensioner plunger radial limit plane 4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com