Optimal design method of embedded piezoelectric branch damping for general blade disk structure

A technology for optimizing design and disk structure, applied in design optimization/simulation, calculation, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

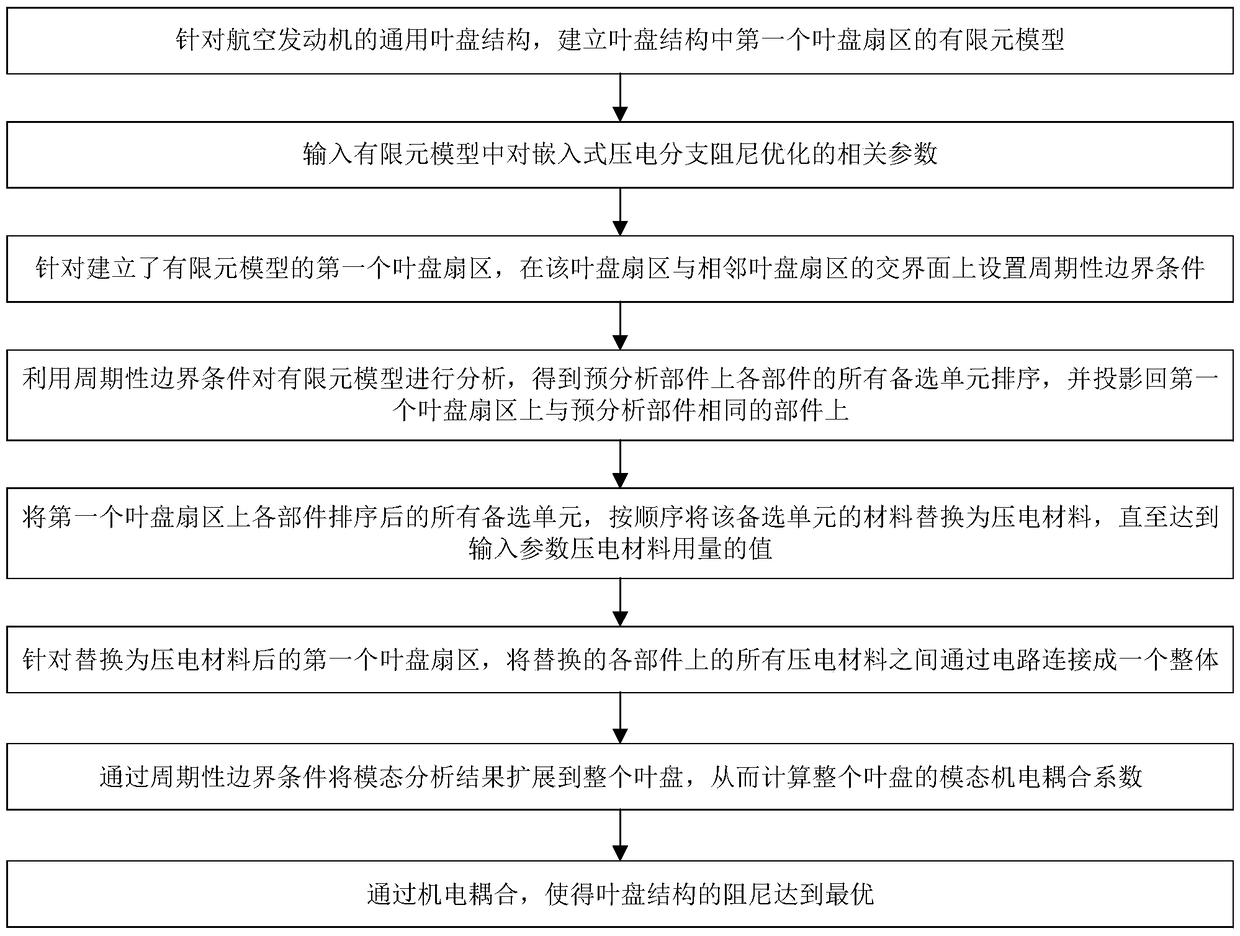

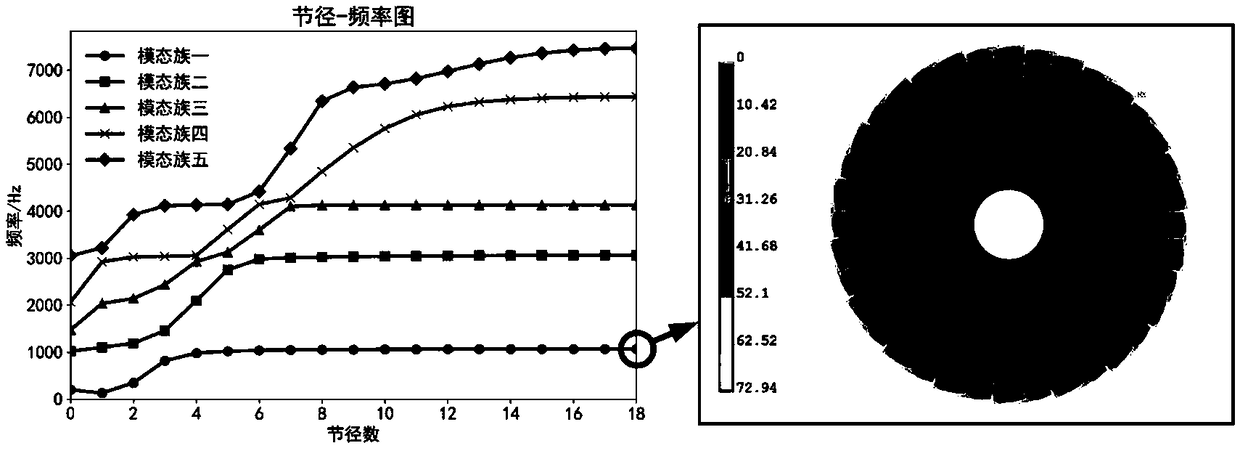

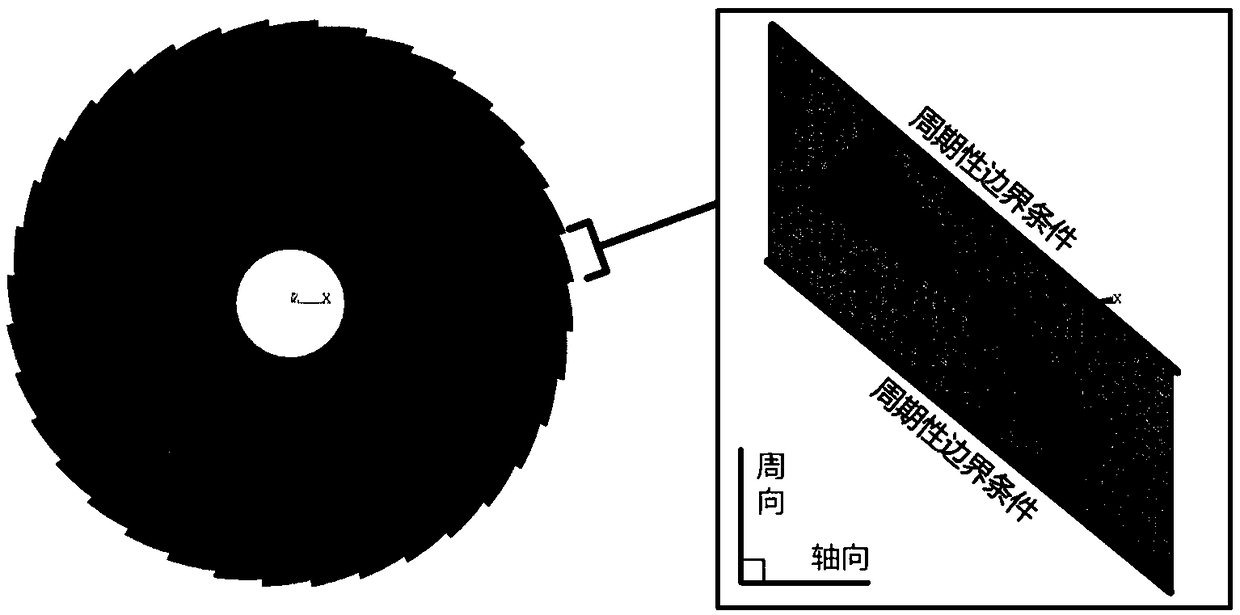

[0070] The invention discloses an embedded piezoelectric branch damping optimization design method for a general blisk structure, based on a finite element model and analysis technology, and can be completed by using any existing commercial / open source finite element platform. The method includes the following steps: first, establish a finite element model of the blisk structure and input relevant parameters; calculate the potential electric field intensity corresponding to the specified mode; then, limit the quality of the piezoelectric material and optimize the embedded position of the piezoelectric material on the specified component; Finally, the circuit connection mode of the piezoelectric material is designed; and the modal electromechanical coupling coefficient is calculated; under the given amount of piezoelectric material, the arrangement posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com