Digital detection method of large-size skin based on laser tracker

A laser tracker and detection method technology, applied in the direction of electrical digital data processing, instruments, measuring devices, etc., can solve the problems of unstable measurement results, low detection accuracy, and difficulty in mass production of aircraft, so as to improve reliability and detection efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

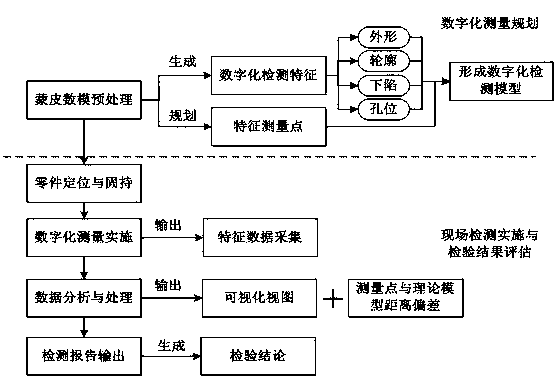

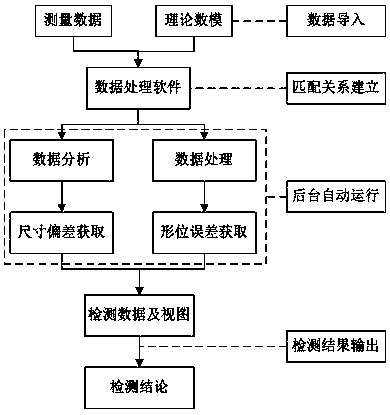

[0042] see figure 1 The large-scale skin digital detection method based on laser tracker, the specific steps are as follows:

[0043] 1) Skin digital-analog preprocessing

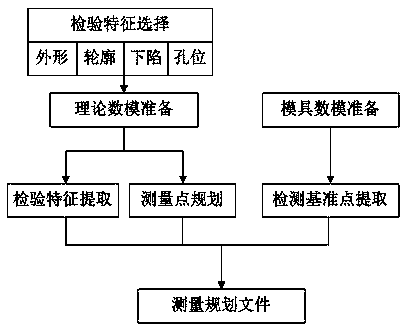

[0044] The process of skin digital model pretreatment is as follows: figure 2 As shown, its main function is to extract detection features and plan measurement paths:

[0045] a. Extract detection features

[0046] The physical features in the skin digital model cannot be recognized by the analysis software SA of the detection system, so it is necessary to convert the skin digital model into point, line and surface features that can be recognized by the analysis software SA in CATIA, and the extracted detection features will be used as Theoretical data for data analysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com