Packaging method for biological characteristic optical sensor of wearable equipment

A technology of optical sensor and packaging method, which is applied in the field of optoelectronics, can solve problems affecting user experience, module occupancy, large space, etc., and achieve the effects of reducing space occupancy, increasing integration, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

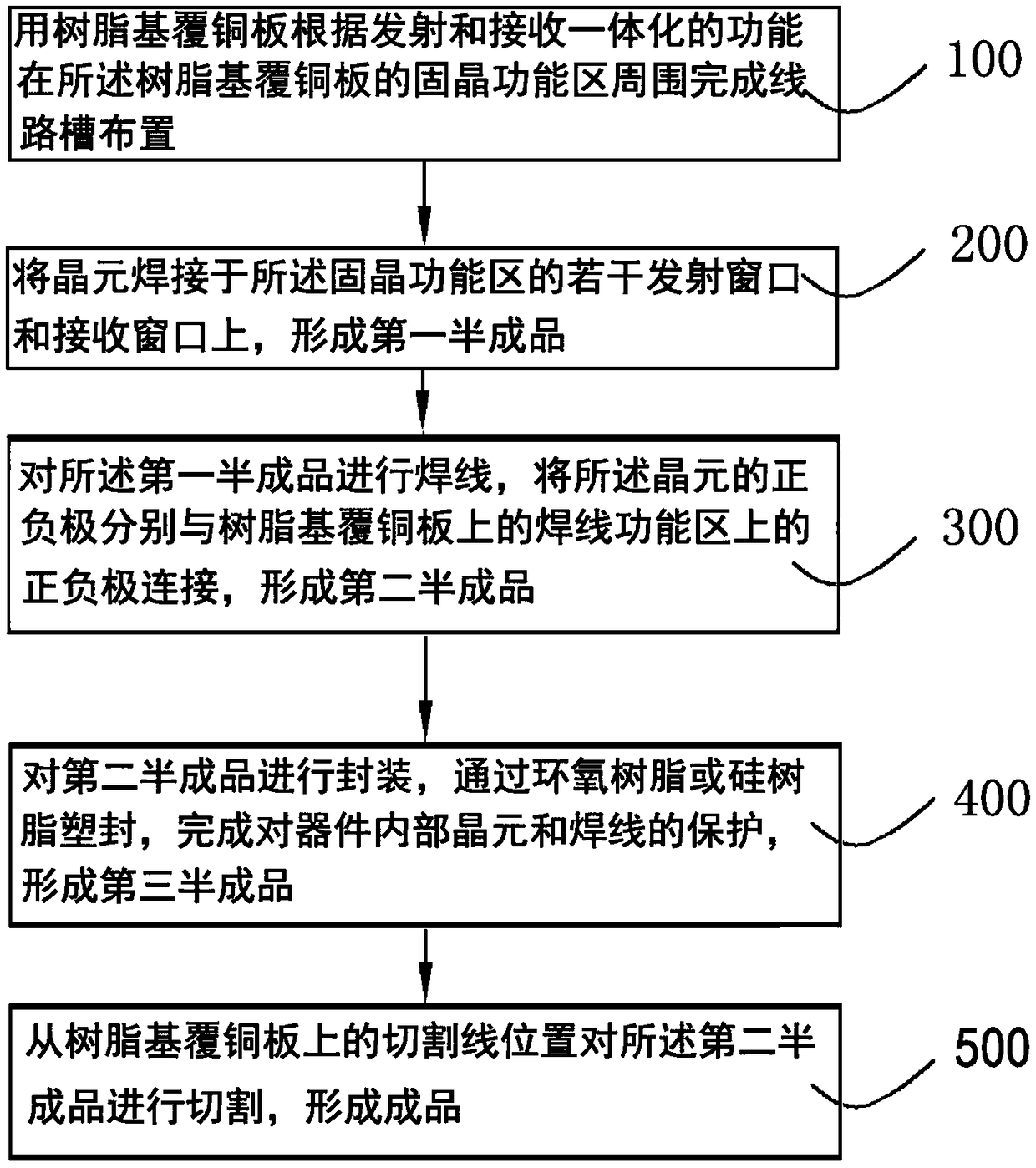

[0036] A method for encapsulating a biometric optical sensor of a wearable device, comprising the following specific steps:

[0037] Circuit arrangement step 100: use the resin-based copper-clad laminate to arrange circuit grooves around the functional area of the resin-based copper-clad laminate according to the integrated function of transmitting and receiving.

[0038] Specifically, a resin-based copper-clad laminate is selected. Since the resin-based copper-clad laminate has a high glass transition temperature, excellent dielectric properties, low thermal expansion rate, and good mechanical properties, the resin-based copper-clad laminate is selected as the package. According to different needs, line grooves are arranged on the resin-based copper-clad laminates. Each resin-based copper-clad laminate has several windows, and the resin-based copper-clad laminates are also preset with cutting lines. Specifically, the size of the resin-based copper-clad laminate is selected ...

Embodiment 2

[0051] A method for encapsulating a biometric optical sensor of a wearable device, comprising the following specific steps:

[0052] Circuit arrangement step 100: use the resin-based copper-clad laminate to arrange circuit grooves around the functional area of the resin-based copper-clad laminate according to the integrated function of transmitting and receiving.

[0053] Specifically, a resin-based copper-clad laminate is selected. Since the resin-based copper-clad laminate has a high glass transition temperature, excellent dielectric properties, low thermal expansion rate, and good mechanical properties, the resin-based copper-clad laminate is selected as the package. According to different needs, line grooves are arranged on the resin-based copper-clad laminates. Each resin-based copper-clad laminate has several windows, and the resin-based copper-clad laminates are also preset with cutting lines. Specifically, the size of the resin-based copper-clad laminate is selected ...

Embodiment 3

[0068] A method for encapsulating a biometric optical sensor of a wearable device, comprising the following specific steps:

[0069] Circuit arrangement step 100: use the resin-based copper-clad laminate to arrange circuit grooves around the functional area of the resin-based copper-clad laminate according to the integrated function of transmitting and receiving.

[0070] Specifically, a resin-based copper-clad laminate is selected. Since the resin-based copper-clad laminate has a high glass transition temperature, excellent dielectric properties, low thermal expansion rate, and good mechanical properties, the resin-based copper-clad laminate is selected as the package. According to different needs, line grooves are arranged on the resin-based copper-clad laminates. Each resin-based copper-clad laminate has several windows, and the resin-based copper-clad laminates are also preset with cutting lines. Specifically, the size of the resin-based copper-clad laminate is selected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com