Vehicle frame and spraying rod double-leveling high-ground-gap electric plant protection machine based on vertical lifting

A vertical lift, plant protection machine technology, applied in vehicle parts, devices for capturing or killing insects, substructures, etc., can solve the problem of double-leveling high ground clearance plant protection machines without a good solution, difficult field transfer, large height difference, etc. problem, to achieve the effect of increasing battery life, good automatic leveling performance, and good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

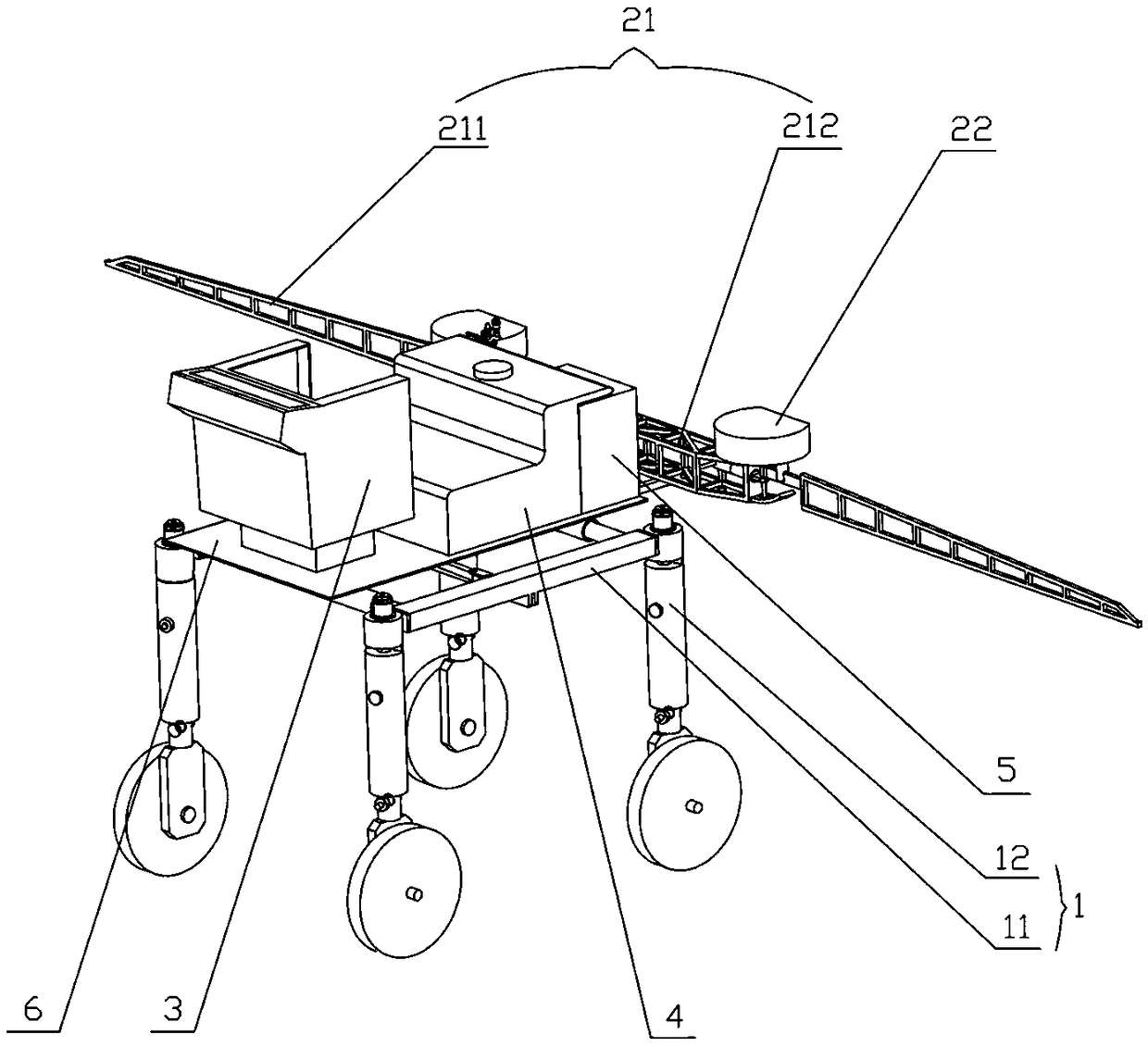

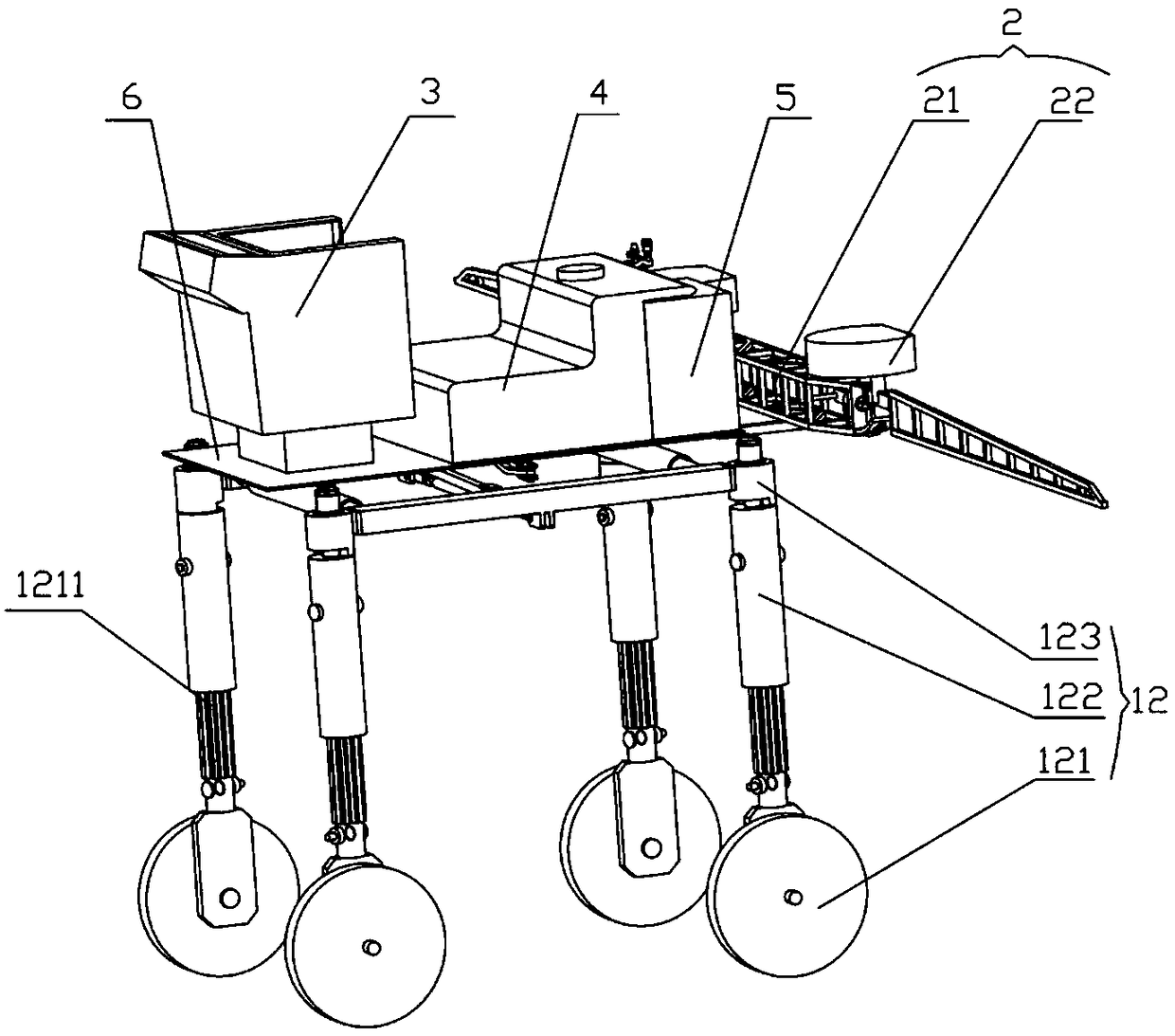

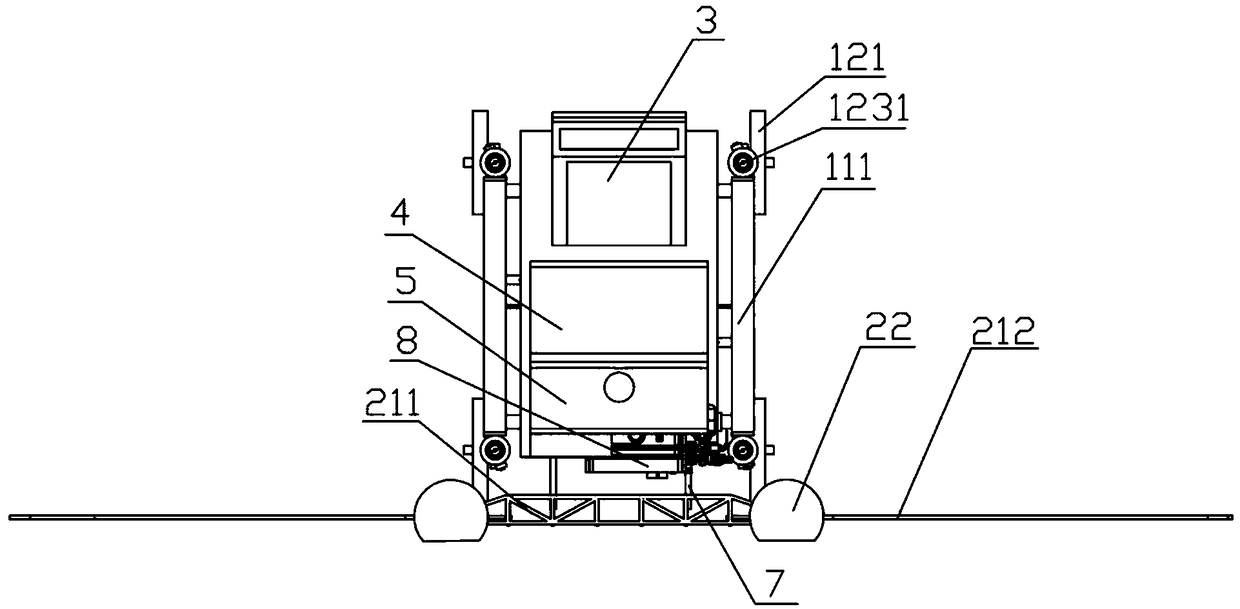

[0031] like Figure 1 to Figure 9As shown, a double-leveling high-ground-gap electric plant protection machine based on a vertical lifting frame spray boom includes a levelable vehicle frame 1, an automatic leveling spray boom system 2, an operation console 3, a profiling medicine box 4 and The battery 5 used to provide electric energy to the entire plant protection machine, the frame 1 is provided with a frame plate 6, the operation console 3, the profiling medicine box 4 and the battery 5 are installed on the frame plate 6 in sequence, and the spray boom is automatically leveled The system 2 is fixed on one end of the vehicle frame 1 through the boom mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com