Tail-filling injection medicine-adding plastic ampoule and manufacturing method thereof

A technology for plastic ampoules and tail irrigation, applied in the field of pharmaceutical packaging, can solve the problems of needle stick injuries, increased pollution risks, cuts of medical staff, etc., and achieves the effects of reducing usage, reducing workload, and facilitating transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

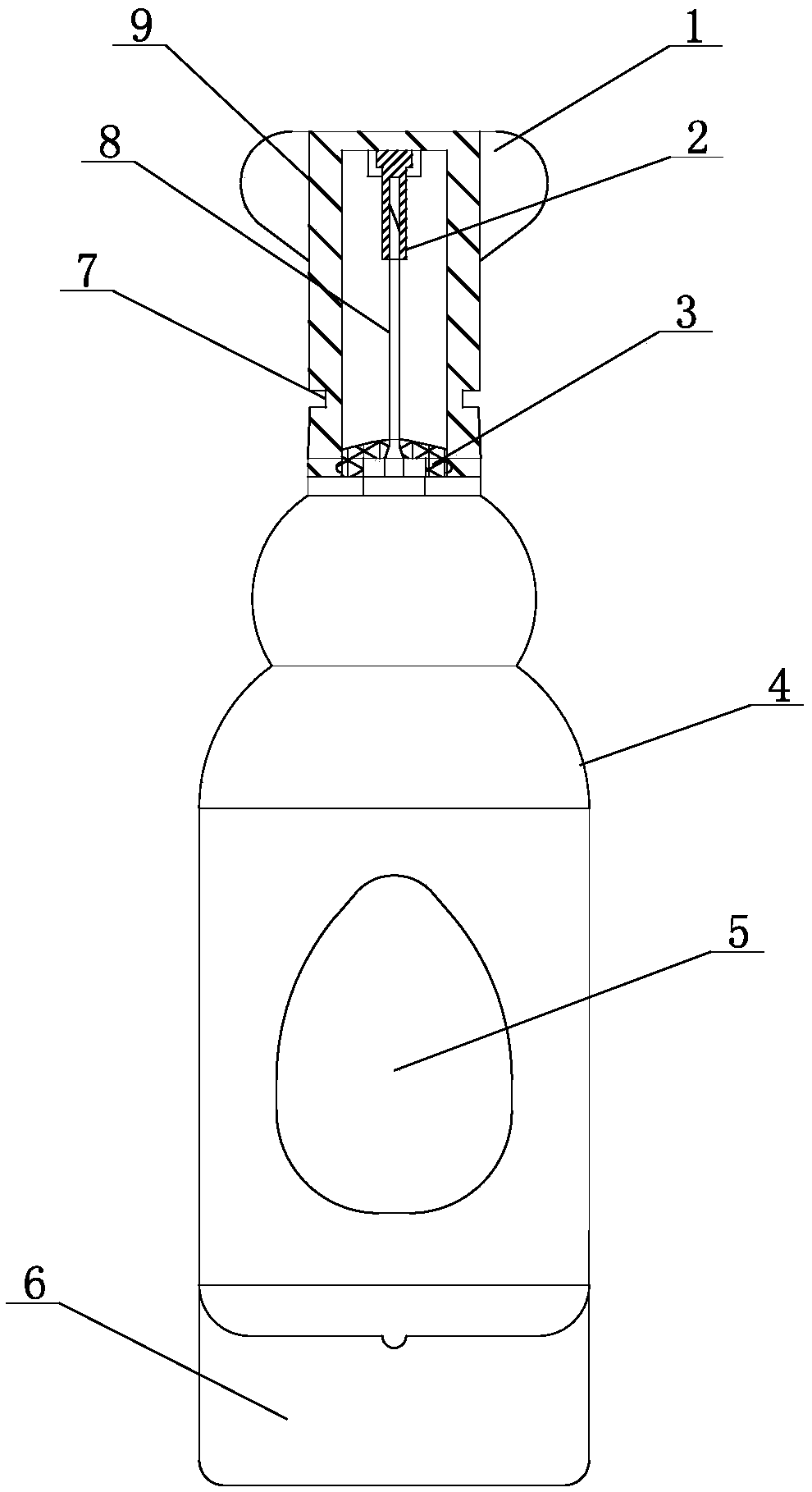

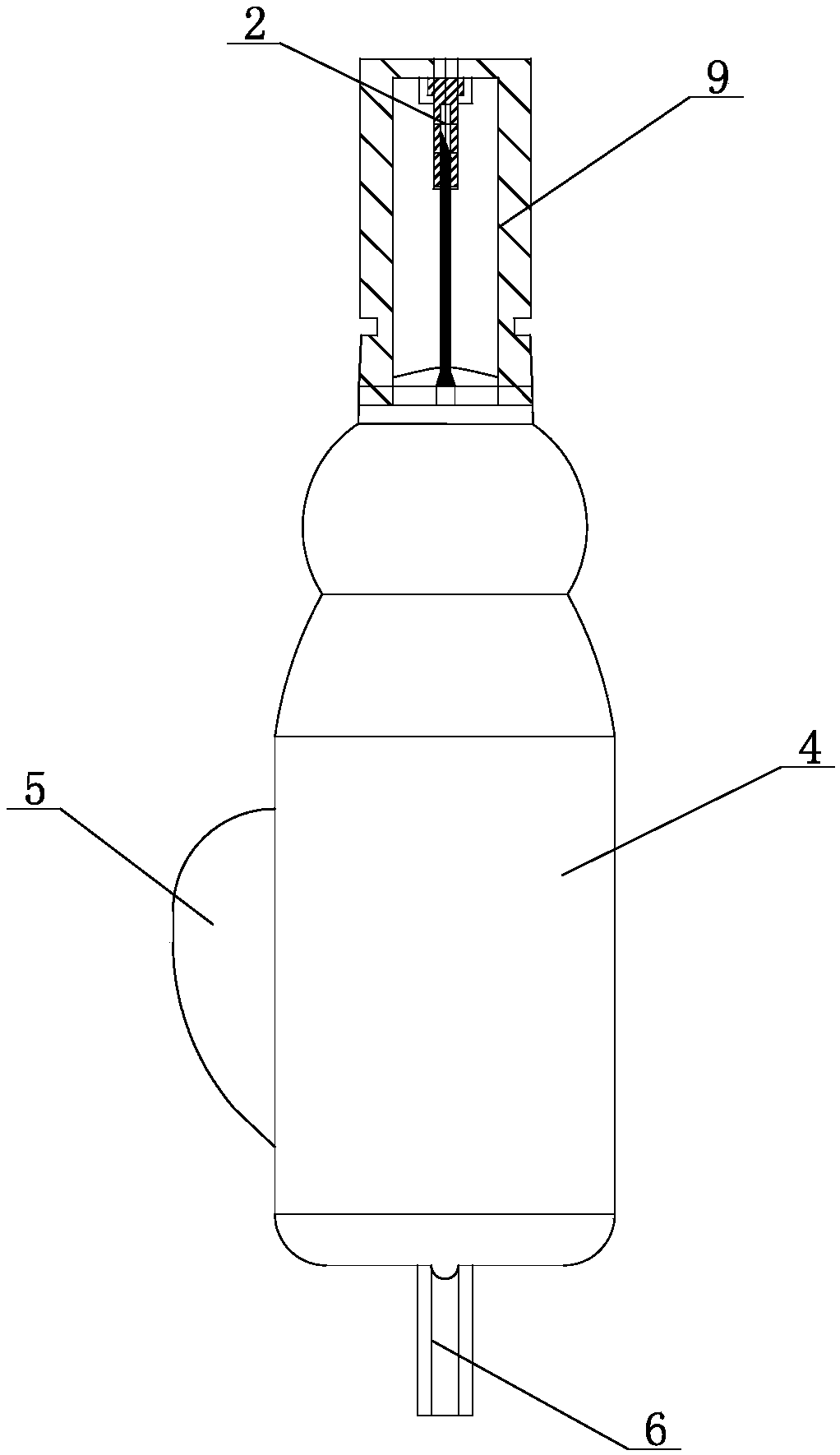

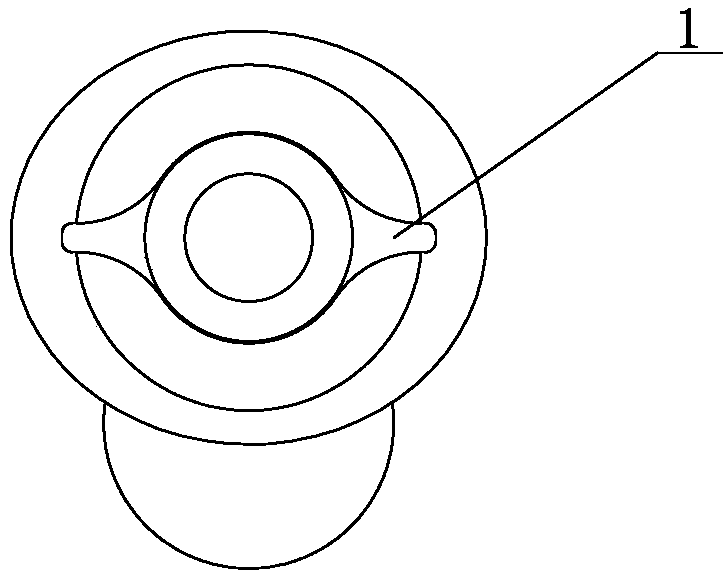

[0030] Such as Figure 1-5 As shown, the tail-filling injection dosing plastic ampoule of the present invention includes an ampoule bottle body 4, the ampoule bottle body 4 is a plastic ampoule bottle body 4, and a steel needle base 3 is arranged on the upper end of the ampoule bottle body 4, and the steel needle base 3 is inserted with a steel needle 8, the outer side of the steel needle 8 is set with a twist-off cap 9, the twist-off cap 9 is welded on the ampoule body 4, the twist-off cap 9 is provided with a twist-off groove 7 which is easy to twist off, and the twist-off cap The two sides of the upper part of 9 are provided with twistable handles 1, and the inner top surface of the twisted off cover 9 is fixed with a rubber sleeve 2 that covers the steel needle 8. The rubber sleeve 2 fits to protect and seal the steel needle 8, and is integrally formed with the ampoule bottle body 4. One side of the ampoule bottle body 4 is provided with an extruding chamber 5 for extrudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com