Neodymium-iron-boron rotary hydrogen decrepitation furnace utilizing thermal expansion and cold contraction for pressurizing and sealing

A pressurized sealing, heat expansion and cold contraction technology, applied in the field of metallurgy, can solve the problems of powder magnetic property weakening, fire and other problems, and achieve the effect of magnetic protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

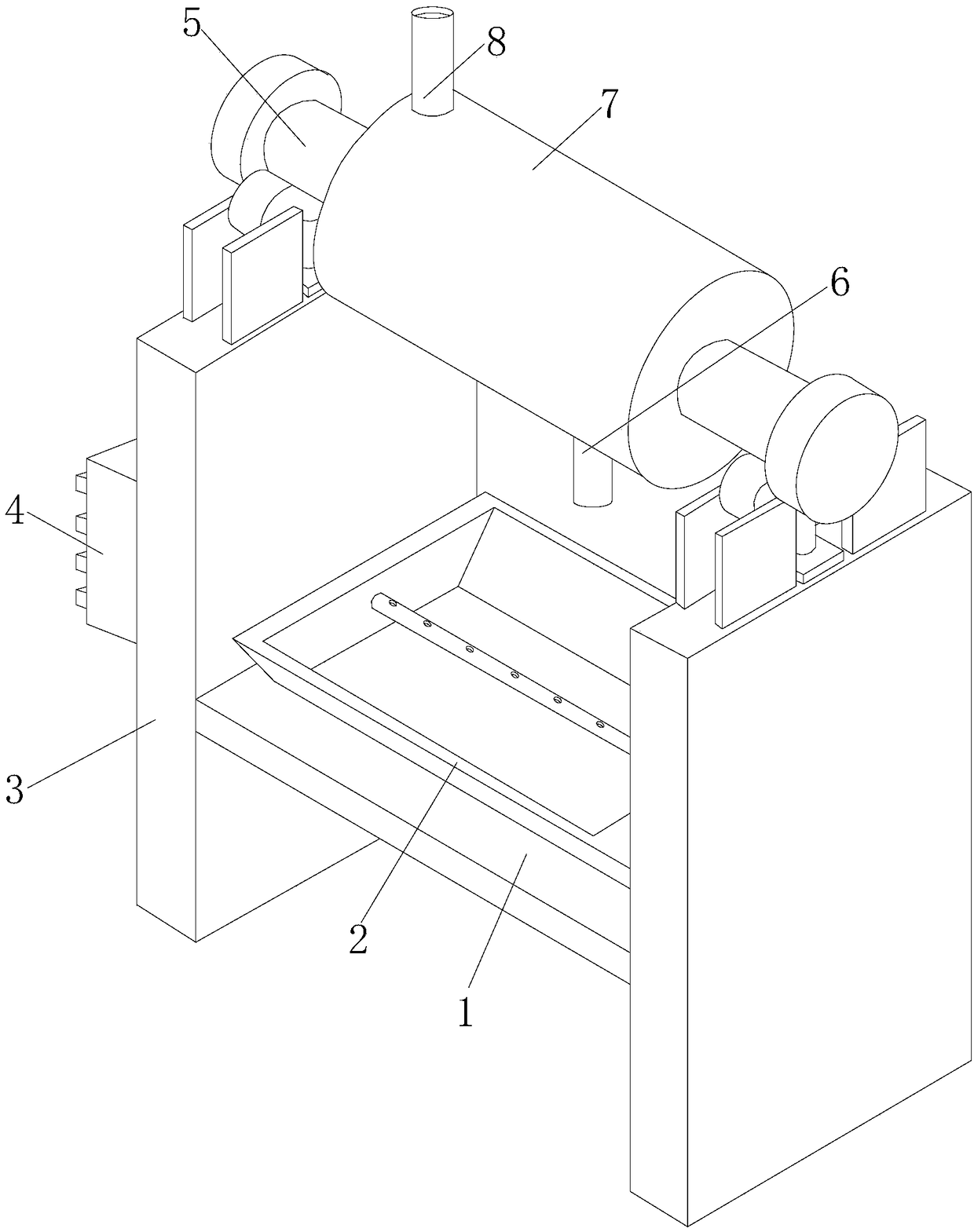

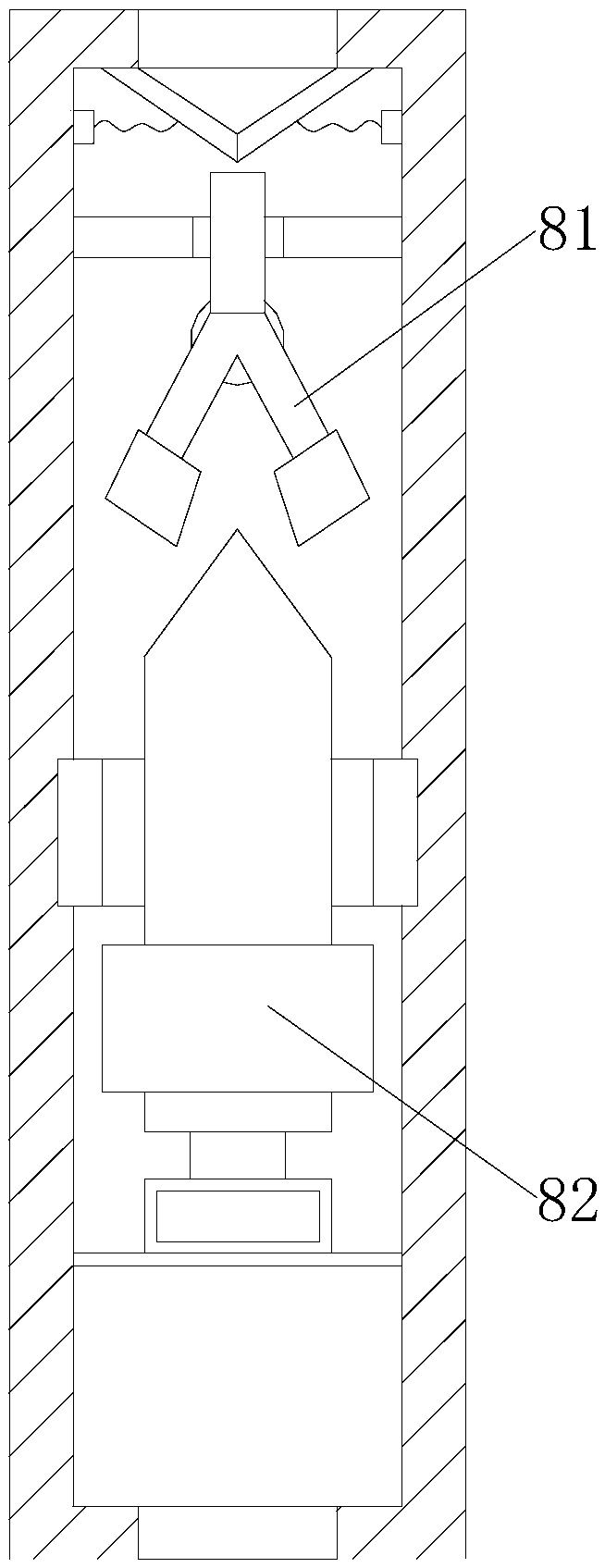

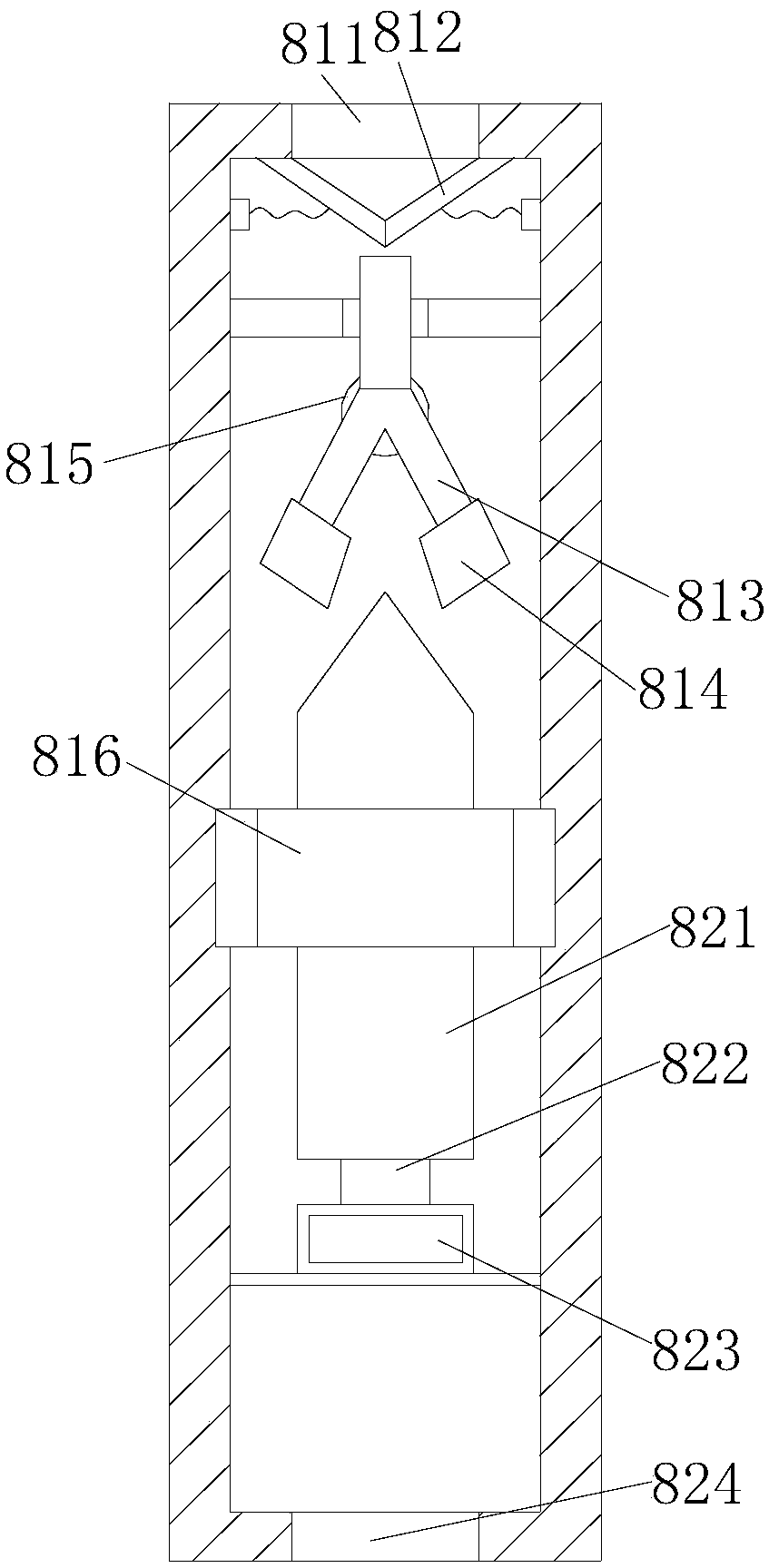

[0027] see Figure 1-8 , the present invention provides a NdFeB rotary hydrogen smashing furnace using thermal expansion and cold contraction to pressurize and seal. Pipe 6, hydrogen crushing furnace 7, feeding pipe 8, the cage 3 is provided with two and installed on both sides of the support base plate 1, the lower end of the desuperheater 2 is fitted with the upper end of the support base plate 1, The right side of the controller 4 is welded to the left side of the upper end of the cage 3, the right side of the rotating rod 5 runs through the middle section of the lower end of the left side of the hydrogen crushing furnace 7, and the lower end of the feed pipe 8 is embedded in the installation In the upper end of the left side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com