Optical fiber wiredrawing annealing device

An annealing device and wire drawing technology, which is applied in the field of optical fiber drawing, can solve problems such as temperature gradient control, optical fiber fluctuation, and flow field chaos in the tube, and achieve the effects of reducing optical fiber vibration, stable air flow, and good warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

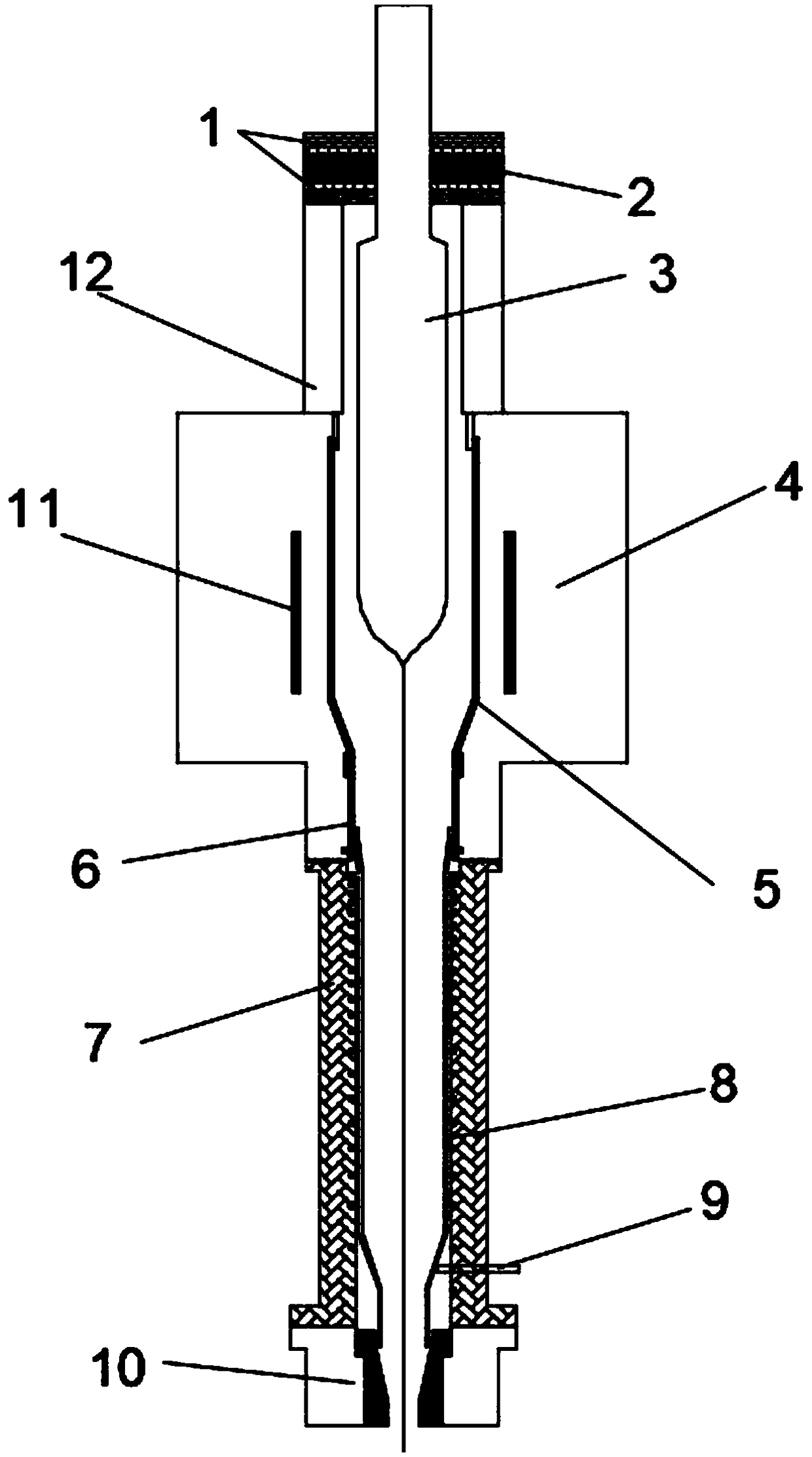

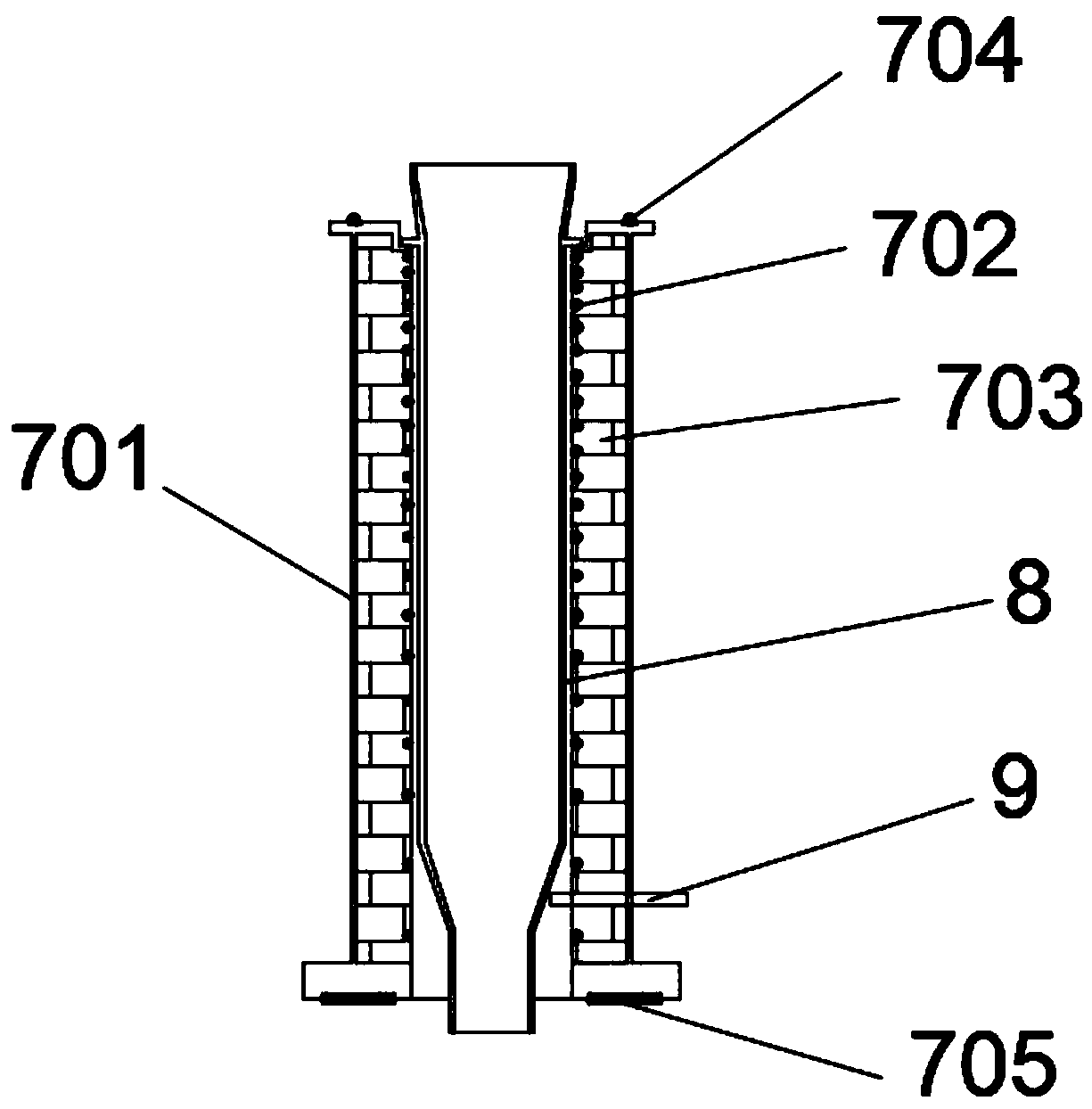

[0029] as attached figure 1 The optical fiber drawing and annealing device shown includes a buffer cylinder 12 at the upper end of the graphite drawing furnace 4, a graphite ring 1, a graphite soft felt 2, a formed graphite tube 5, a graphite connecting tube 6, an annealing furnace 7, a glass guide tube 8, and a measuring tube. Thermocouple 9, sealing ring 10. The inner diameter of the heating body 11 is 320 mm, and the height of the heating body is 280 mm; the inner diameter of the graphite forming tube 5 is 250 mm, the thickness is 6 mm, the length of the tapered surface is 180 mm, and the inner diameter of the bottom is 80 mm; the inner diameter of the buffer tube 12 is 230 mm, and the height is 2200 mm; The diameter of the handle rod of the optical fiber preform 3 is 60mm, and the size error is controlled within 0.2mm; the inner diameter of the graphite ring 1 is 60.5mm, the outer diameter is 360mm, and the thickness is 10mm; the inner diameter of the graphite soft felt 2 ...

Embodiment 2

[0032] as attached figure 1 The optical fiber drawing and annealing device shown includes a buffer cylinder 12 at the upper end of the graphite drawing furnace 4, a graphite ring 1, a graphite soft felt 2, a formed graphite tube 5, a graphite connecting tube 6, an annealing furnace 7, a glass guide tube 8, and a measuring tube. Thermocouple 9, sealing ring 10. The inner diameter of the heating body 11 is 180 mm, and the height of the heating body is 180 mm; the inner diameter of the graphite forming tube 5 is 120 mm, the thickness is 4 mm, the length of the tapered surface is 100 mm, and the inner diameter of the bottom is 50 mm; the inner diameter of the buffer tube 12 is 110 mm, and the height is 1000 mm; The diameter of the handle rod of the optical fiber preform 3 is 50 mm, and the size error is controlled within 0.2 mm; the inner diameter of the graphite ring 1 is 50.5 mm, the outer diameter is 200 mm, and the thickness is 10 mm; the inner diameter of the graphite soft fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com