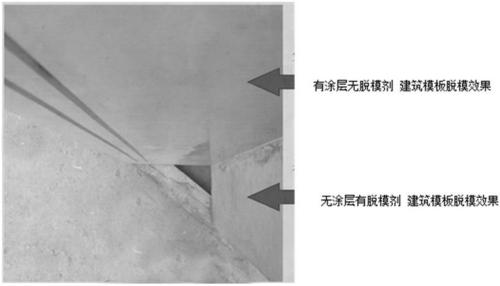

Demolding coating for building formworks

A technology for building templates and demoulding, which is applied in coatings, epoxy resin coatings, etc., to achieve the effects of cost reduction, process convenience, and reduction of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]

[0032] Dissolve tetrabutyl titanate in acetone, spray it on the surface of graphite, and wait for the acetone to volatilize completely; mix and stir epoxy resin E-44 and 650 curing agent, add the treated graphite, then fully stir, and coat on the surface of building formwork , curing at room temperature.

Embodiment 2

[0034] Flexible Ceramic Resin MB-1 A 87 parts

[0035] Flexible ceramic resin curing agent MB-1 B 13 parts

[0036] Graphite 150 parts

[0037] Mix the hybrid resin, curing agent and graphite thoroughly, apply it on the surface of the building formwork, and cure it at room temperature.

Embodiment 3

[0039]

[0040] Dissolve tetrabutyl titanate in ethanol, add graphite and stir, wait until ethanol volatilizes, and graphite coupling is completed, fully stir and mix the hybrid resin, curing agent and coupled graphite, and scrape it on the surface of the building formwork, at room temperature solidified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com