Life extension method of hot stamping forming mold for high-strength steel plate and application

A technology of hot stamping and high-strength steel plates, applied in heat treatment furnaces, manufacturing tools, heat treatment equipment, etc., can solve the problems of ignoring the whole chain technology of molds, and achieve the effects of reducing mold costs, increasing mold life, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

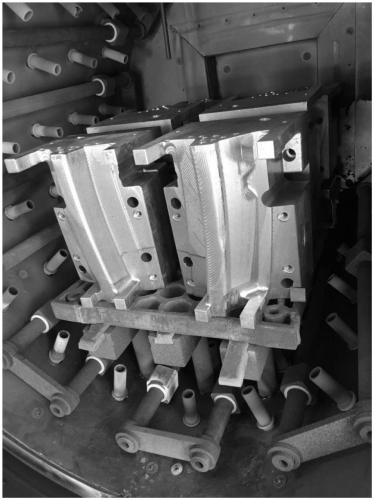

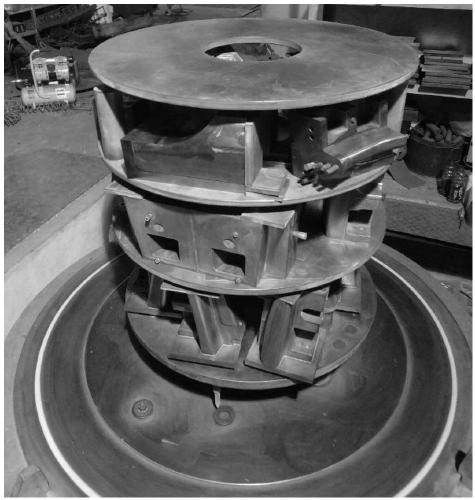

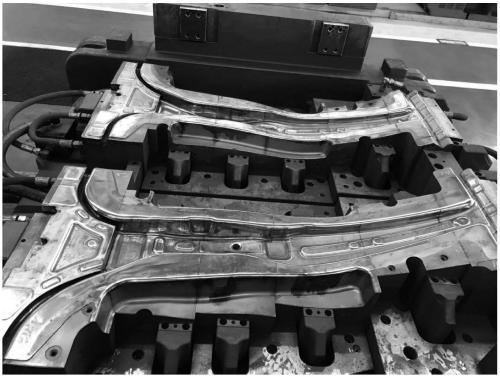

[0030] In this embodiment, the hot stamping forming die insert of the high-strength steel plate for automobiles made of 4Cr5Mo2V steel is used for testing, and the specific details are as follows:

[0031] Step 1. Vacuum heat treatment: Heat all the mold inserts that have been roughly machined to 1030°C in a vacuum furnace for a certain period of time, then perform high-pressure (8Bar) gas quenching at a cooling rate of ≥0.047°C / s, and wait for the surface of the mold to cool to ≤50°C, cool the core to ≤150°C, and then temper 3 times in a vacuum furnace at 530°C, 545°C and 560°C respectively, and finally adjust the hardness of the mold insert to 53-55HRC for finishing ;

[0032] Step 2. Mold pretreatment: Bake all the inserts of the automobile high-strength steel plate hot stamping forming mold, and then clean the surface after cooling out of the oven to remove the mold holes, mold cavity and surface dust, residual rubber products, pollutants and others Attachments, wipe the ...

Embodiment 2

[0037] In this embodiment, the hot stamping forming die insert of the high-strength steel plate for automobiles made of 4Cr5MoSiV steel is used for testing, and the specific details are as follows:

[0038] Step 1. Vacuum heat treatment: Heat all the mold inserts that have been roughly machined to 1020°C in a vacuum furnace for a certain period of time, then perform high-pressure (6Bar) gas quenching at a cooling rate of ≥0.047°C / s, and wait for the surface of the mold to cool to ≤50°C, cool the core to ≤150°C, and then temper three times in a vacuum furnace at temperatures of 540°C, 540°C and 560°C respectively, and finally adjust the hardness of the mold insert to 52-54HRC for finishing ;

[0039] Step 2. Mold pretreatment: Bake all the inserts of the automobile high-strength steel plate hot stamping forming mold, and then clean the surface after cooling out of the oven to remove the mold holes, mold cavity and surface dust, residual rubber products, pollutants and others A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com