Method of reinforcing surface structure by laser shock

A technology of laser shock strengthening and surface structure, which is used in heat treatment equipment, heat treatment process control, manufacturing tools, etc. It can solve the problems of inaccurate intensity control of laser shock treatment, and achieve the effect of improving uniformity and ensuring consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

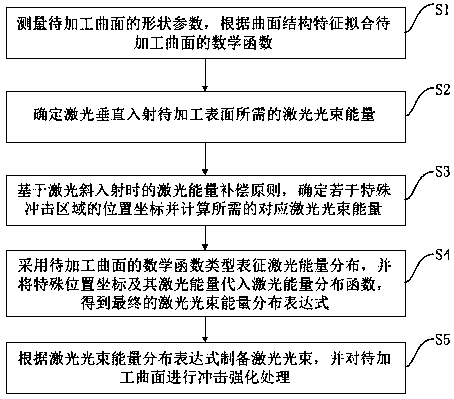

[0035] Such as figure 1 Shown is the flowchart of the method for laser shock strengthening curved surface structure of the present invention, comprises the following steps:

[0036] S1. Measuring the shape parameters of the surface to be processed, deriving the mathematical function type of the structural features of the surface, and fitting the mathematical function expression of the surface to be processed;

[0037] S2. According to the surface strengthening requirements of the material, determine the laser beam energy E required for the laser to be vertically incident on the surface to be processed 0 ;

[0038] S3. Based on the principle of laser energy compensation under the condition of laser oblique incidence, determine the position coordinates of several special impact areas and calculate the corresponding required laser beam energy E;

[0039] S4. Use the mathematical function type of the surface to be processed to characterize the laser energy distribution to obtain...

Embodiment 2

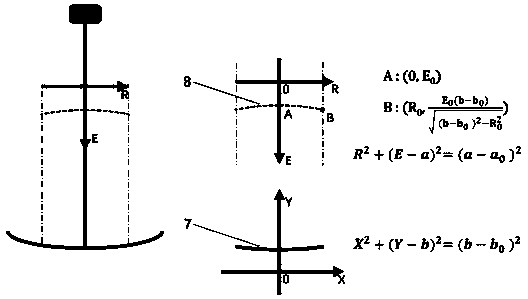

[0054] This embodiment is the application of the equation that the mathematical function type of the plane or curved surface to be processed in Embodiment 1 is a circle. In this embodiment:

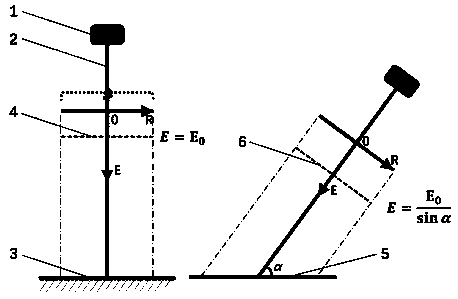

[0055] Such as figure 2 As shown, when the laser beam 2 is vertically incident on the plane 3 to be processed, the energy of the laser beam is E 0 , its distribution is represented by plane 4; when the laser beam 2 obliquely hits the plane 5 to be processed, the angle between the laser beam 2 obliquely incident on the plane to be processed and the horizontal plane of the laser 1 is α, then the angle between the laser beam 2 obliquely incident on the plane to be processed Laser beam energy E needs to be increased to Its distribution is represented by plane 6 .

[0056] Such as Figure 4 As shown, when the laser beam 2 is vertically incident on the curved surface 9 to be processed, the energy distribution of the laser beam 2 is represented by a curved surface 10; In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com