Pile forming Equipment and method for modulus controlled plain concrete pile

A plain concrete pile and pile-forming technology is applied in the field of control-modulus plain concrete pile-forming equipment, which can solve the problems of low work efficiency, influence on concrete strength, influence on pile-forming quality, etc., and achieve the effect of improving pile-forming efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

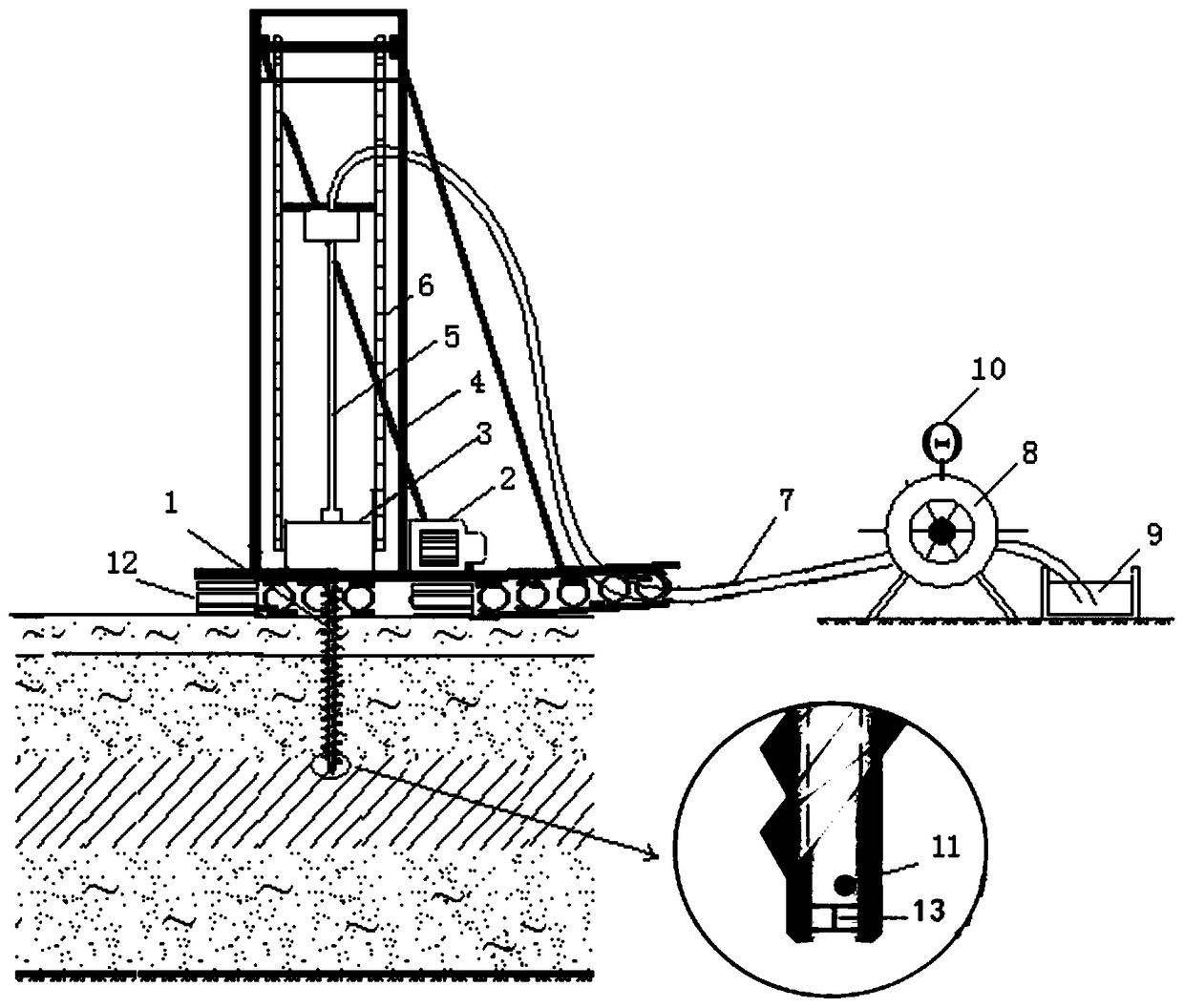

[0020] Such as figure 1 Shown: a control modulus pile forming equipment, including: drill bit 1, motor 2, drilling rig control platform 3, drill frame 4, drill pipe 5, force transmission chain 6, concrete delivery pipe 7, concrete pump 8, concrete pool 9. Drilling rig control panel 10, pressure sensor 11, flap type concrete slurry injection valve 12, crawler belt 13. Wherein the drill bit 1 and the drill pipe 5 are all provided with longitudinal through holes, the output port of the concrete pump 8 communicates with the upper end through hole of the drill pipe 5 through the slurry delivery pipe 7, the bottom of the drill pipe 5 is connected with the control platform 3, and the control platform 3 Fixed on the base of the drilling rig, there are two power transmission chains 6 on the left and right, the upper parts of which are respectively connected with the cross bars on the upper part of the drilling frame 4, the lower parts of the transmission chain 6 are respectively connec...

Embodiment 2

[0023] The method for forming piles with pressure balance of controlled modulus piles includes the following steps:

[0024] 1) According to the requirements of superstructure deformation control and bearing capacity, as well as the geological conditions of the site, the concrete strength of the pile body is designed to be C25, the pile length is 27m, the pile diameter is 40cm, and the pile spacing is 2.8m. The plain concrete is provided by the concrete mixing station;

[0025] 2) The pile is formed by using the self-rotating auger bit 1 to drill down from the surface, and at the same time, according to the pressure monitored by the pressure sensor out of the bit, the concrete slurry is pumped into the drill pipe;

[0026] 3) After drilling to a depth of 27m, stop drilling, counter-rotate and raise the drill bit 15cm, apply a trigger force of 10kPa to the concrete slurry in the transmission pipe, that is, automatically open the valve at the bottom of the drill bit (the valve op...

Embodiment 3

[0028] 1) According to the requirements of superstructure deformation control and bearing capacity, as well as the geological conditions of the site, the concrete strength of the pile body is designed to be C25, the pile length is 16m, the pile diameter is 40cm, and the pile spacing is 2.5m. The plain concrete is provided by the concrete mixing station;

[0029] 2) The pile is formed by using the self-rotating auger bit 1 to drill down from the surface, and at the same time, according to the pressure monitored by the pressure sensor out of the bit, the concrete slurry is pumped into the drill pipe;

[0030] 3) After drilling to a depth of 16m, stop drilling, counter-rotate and raise the drill bit 20cm, apply a trigger force of 6kPa to the concrete slurry in the transmission pipe, that is, automatically open the valve at the bottom of the drill bit (the valve opening time is 25 seconds) , the trigger force is continuously applied to realize the uniform lifting of the drill pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com