Finished product protection method after paving and attaching of high polymer waterproof rolling materials

A polymer waterproofing and finished product protection technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of delaying the construction period, welding slag burning and damage, and increased construction costs of damaged coils, so as to reduce the occupation Small space, great operational flexibility, and easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

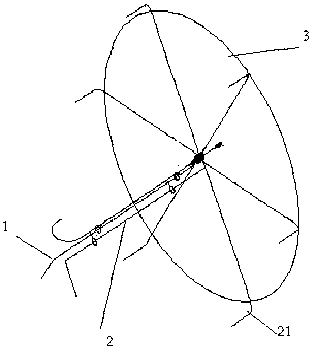

[0021] The invention relates to a method for protecting the finished product after the polymer waterproof coiled material is pasted. The protection device includes the following three parts, namely the operating mechanism, the rotating supporting figure 1 ).

[0022] The process of using this device to protect finished coil products is as follows:

[0023] 1. Assembly of the device: connect and assemble the operating mechanism, the rotating support mechanism and the slag receiving tray in a certain order.

[0024] 2. Extend the device into the bottom of the steel bar at the welding place, and open the device.

[0025] 3. Welding work.

[0026] 4. After the welding is completed, put away the device and take it out from the gap between the horizontal ribs.

[0027] 5. Disassemble the device and put it into the packaging bag.

[0028] Above-mentioned operating mechanism 1 is made up of handle, joystick, limit bolt and limit ring four parts. The handle and joystick of this me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com