Mined metro station second lining buckle arch construction method

A construction method and underground excavation technology, which can be applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of repeated input of manpower and material resources, large space occupation, and long construction period, so as to improve construction efficiency and reduce construction costs. , the effect of reducing resource investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

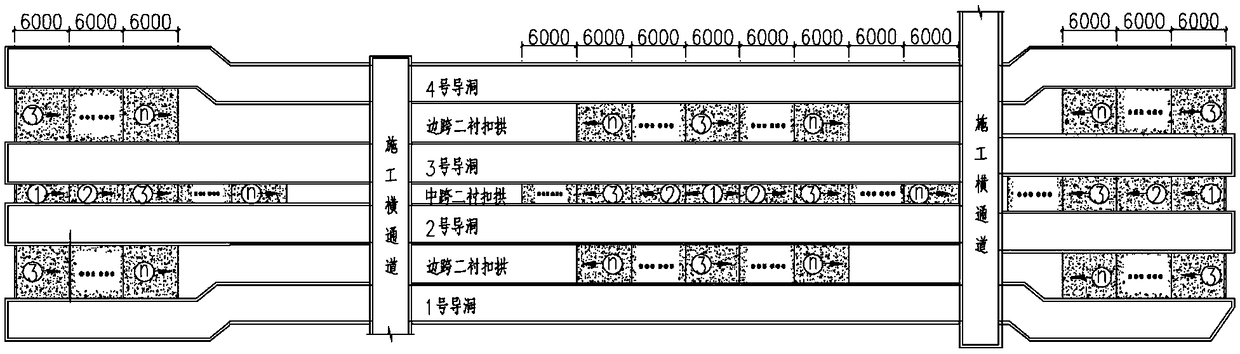

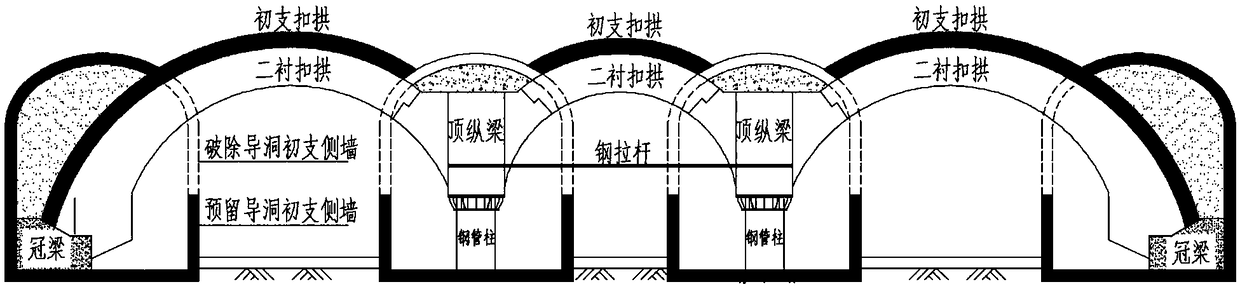

[0055] Such as figure 1 , figure 2 As shown, after the primary support of the middle arch and side arch is penetrated, the side wall of the pilot tunnel is broken in sections, the length of which is 6m at a time, the waterproof layer is laid, the middle arch and the second lining of the side arch are poured backward, and steel tie rods are installed in the middle span along with the top arch , the second lining of the mid-span arch first, staggered 8-12m from the front and back of the second lining of the arches of the two sides, and the second lining of the side arches on both sides was poured symmetrically.

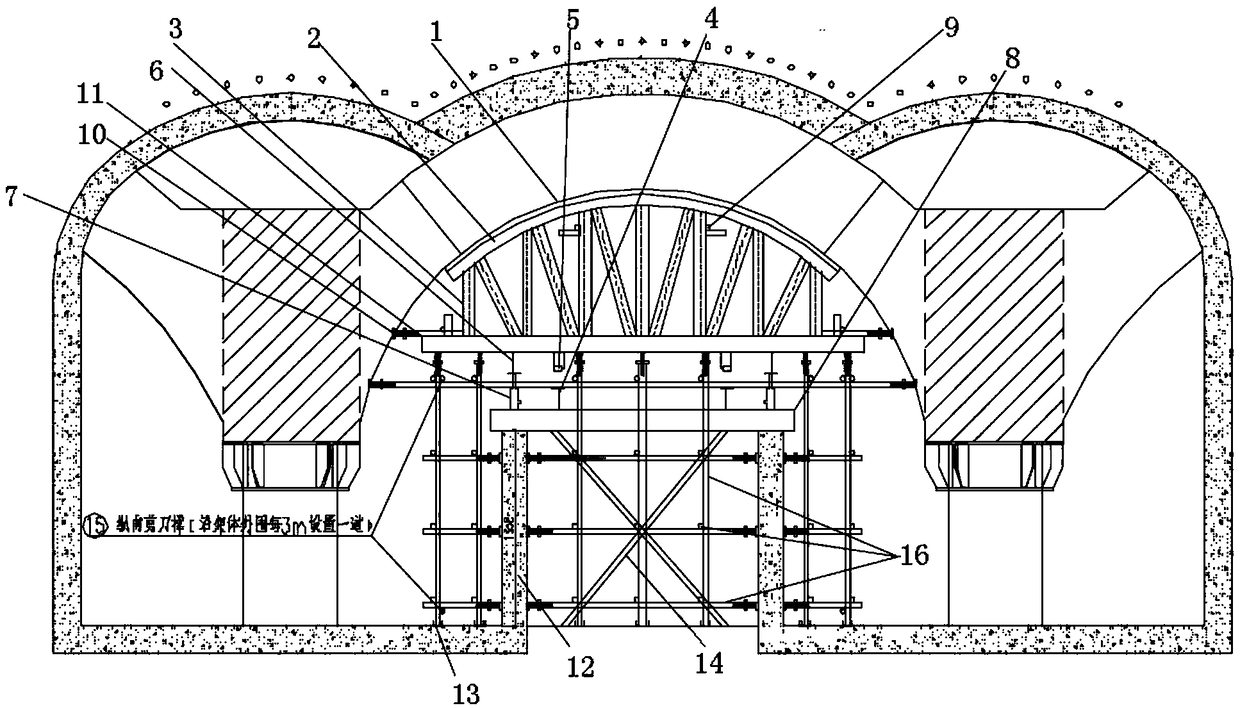

[0056] image 3 , Figure 4 The steel formwork 1 uses a 4mm thick steel plate as the curved steel formwork, the arch 2 uses No. 10 I-shaped steel as the arc-shaped formwork steel arch, and the support 3 uses No. 10 I-shaped steel as the vertical steel arch. Support, the moving track 4 uses No. 20 I-beam as the moving track of the assembled formwork, the pulley 5 use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com