Active feedback control method and device used for installing single blade of fan

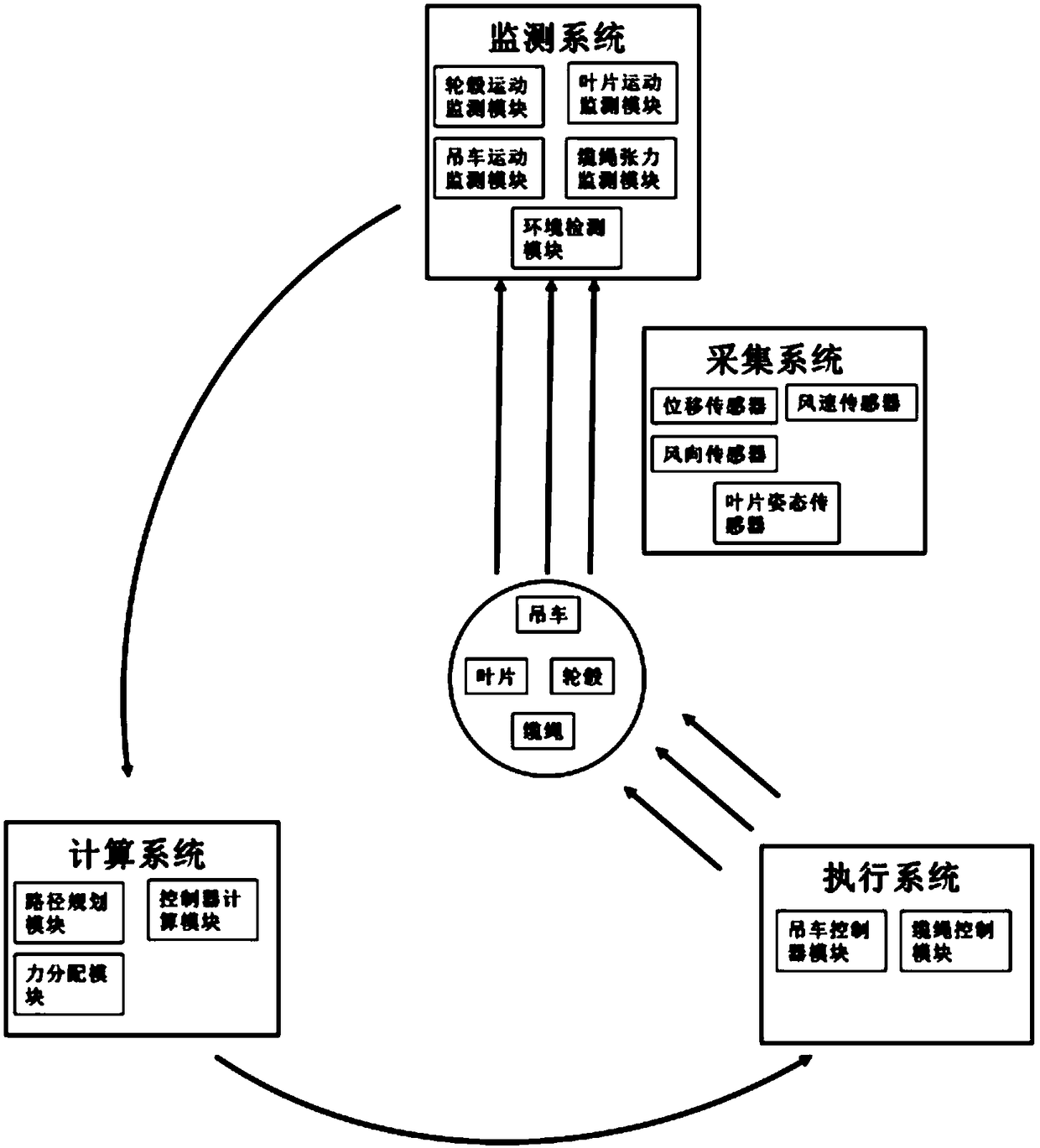

A technology of active feedback and control devices, which is applied in the monitoring of wind turbines, assembly of wind turbines, wind turbines, etc., can solve problems such as increased installation costs, achieve the effect of reducing electricity prices, reducing the total cost of wind turbines, and promoting the use of wind turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and technical solutions, but the present invention is not limited to specific embodiments.

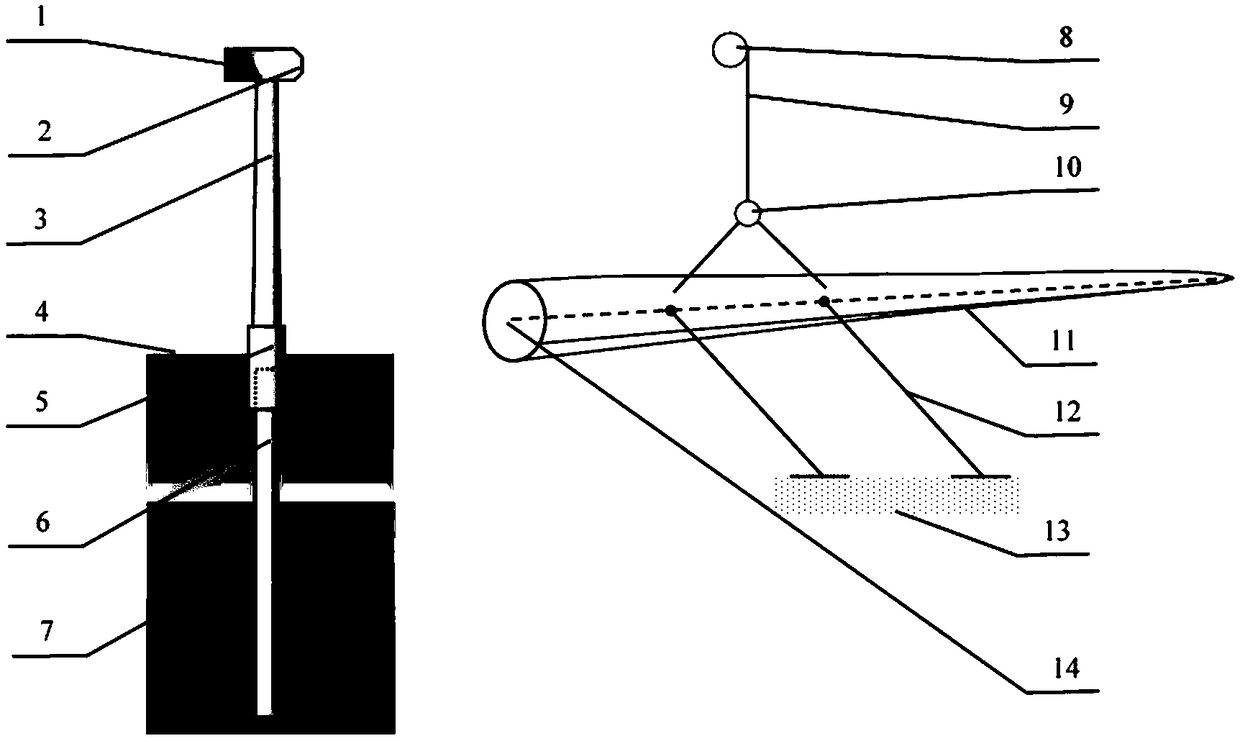

[0019] like figure 1 Shown: A single-blade installation method for wind turbines based on active feedback control.

[0020] When the wind turbine foundation 6, the transition section 5, the tower 3, the nacelle 1, and the hub 2 are installed once. The present invention proposes that the preparatory work of the installation method is the same as that of the traditional installation method.

[0021] Step 101: Tighten the hoisting cable 9, lift the hub 2 from the deck to a corresponding height.

[0022] Step 102: Turn the wheel hub 2 to make the mounting holes horizontal. The blade 11 is connected to the top of the crane 8 through the hoisting cable 9 and the hook 10; one end of the cable 12 with active tension control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com