A multi-point grease automatic lubrication micro-control system for automobile chassis

An automotive chassis, automatic lubrication technology, applied in the lubrication system, engine lubrication, lubrication parts and other directions, can solve the problems of wasting equipment, easy to burn, increase the cost of use, etc., to ensure the supply of lubricating oil, facilitate cleaning and maintenance, The effect of reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

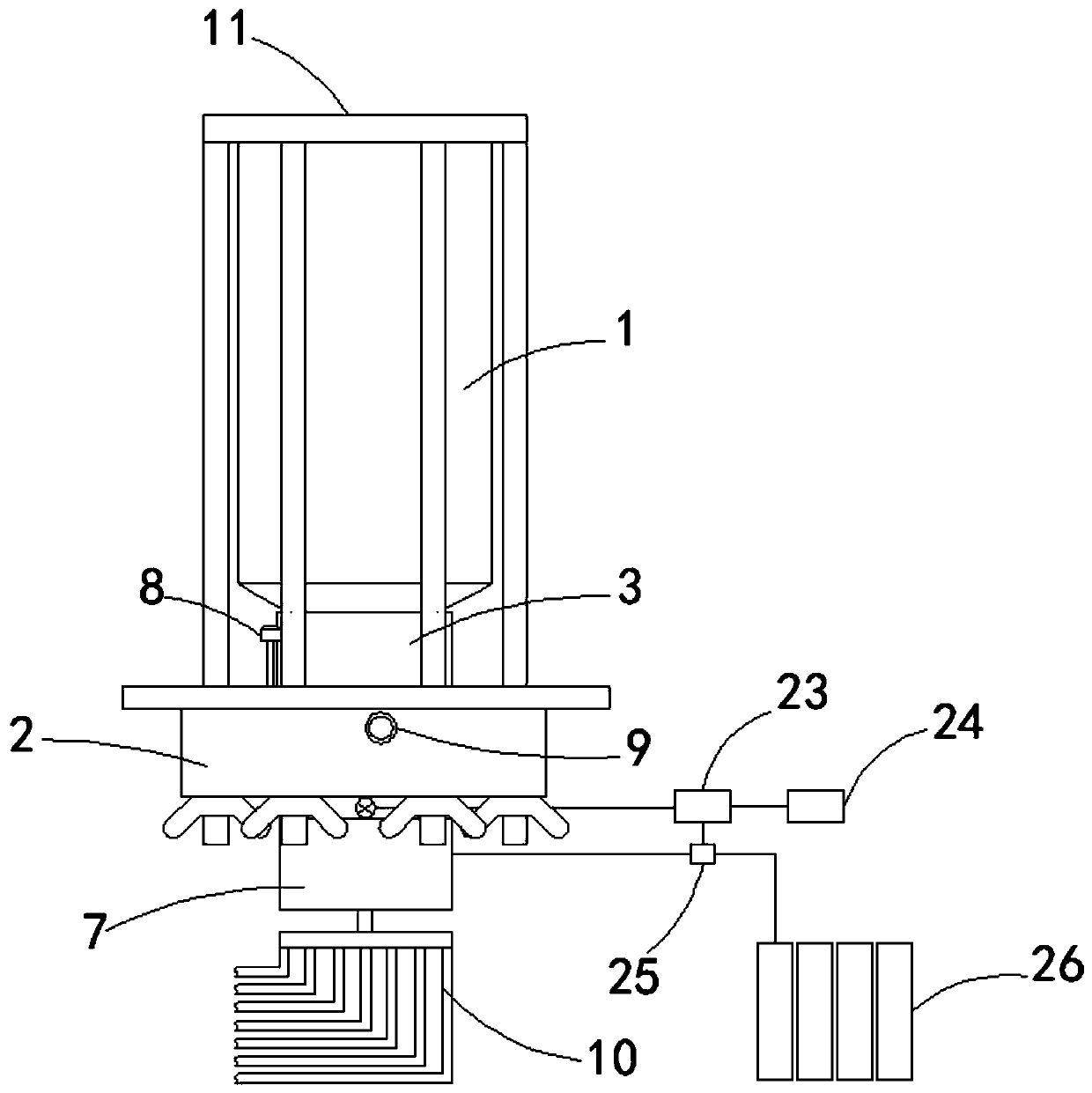

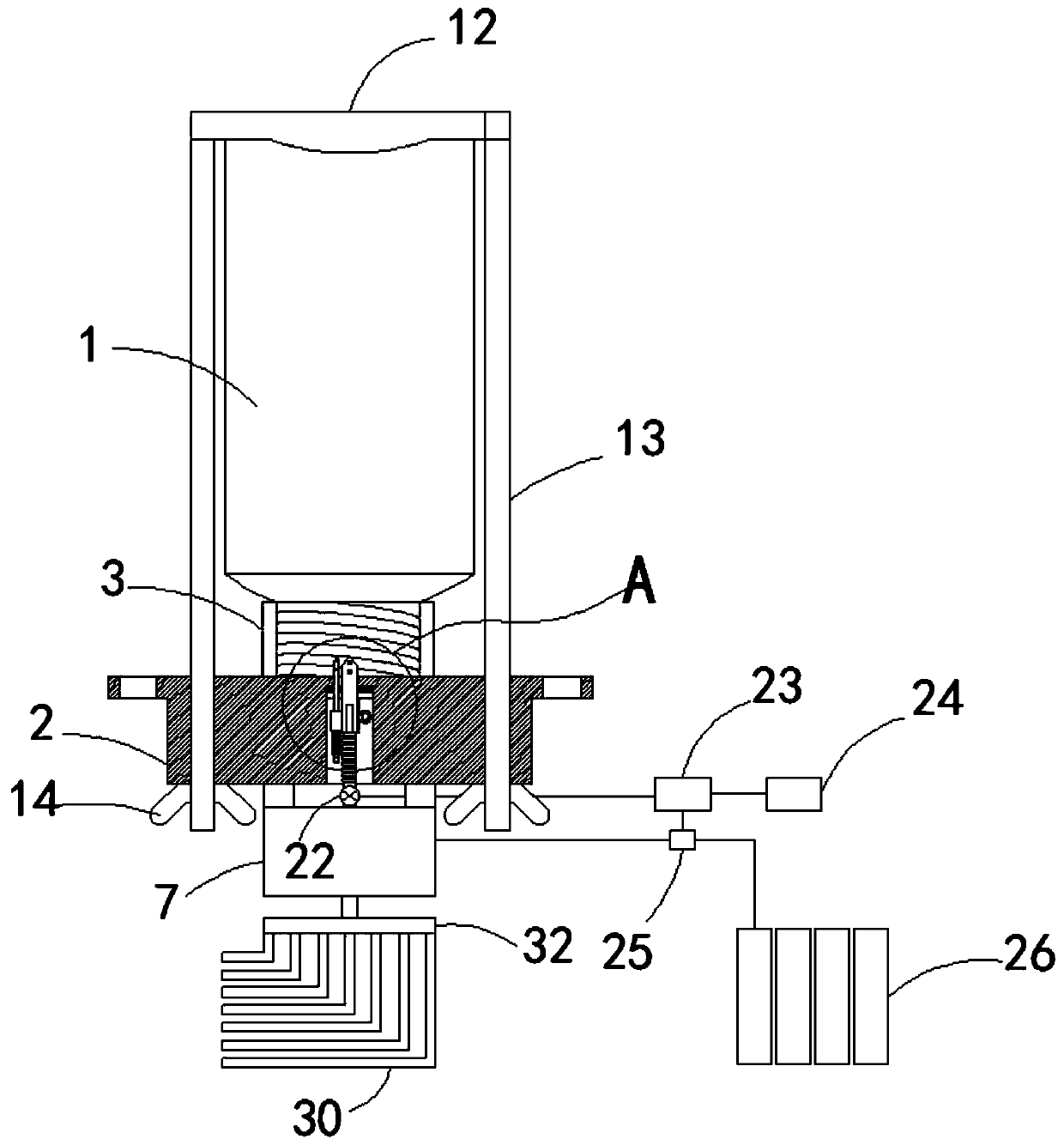

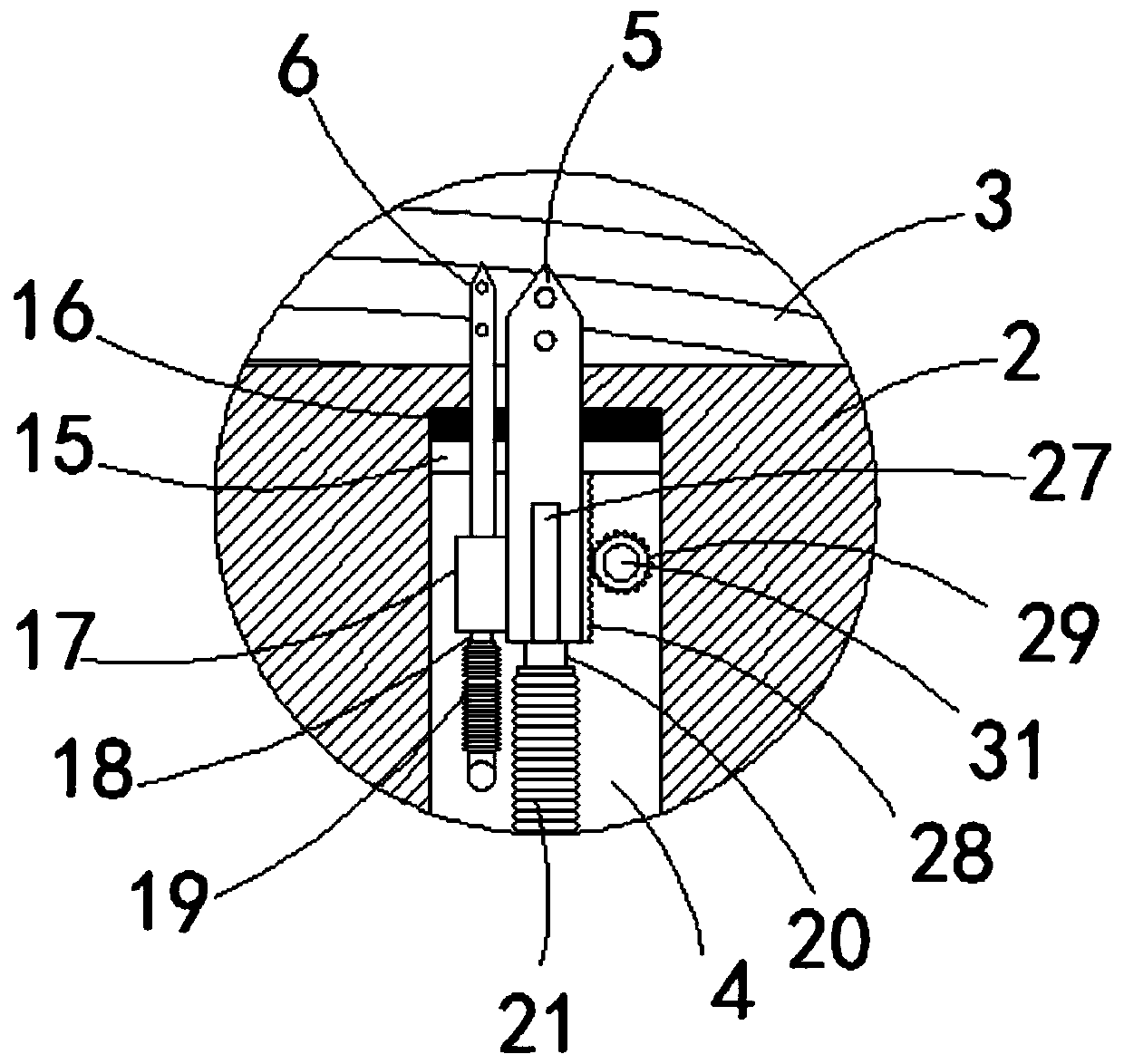

[0022] Such as Figure 1-4 As shown, a multi-point grease automatic lubrication micro-control system for automobile chassis includes a lubricating oil bottle 1 and a mounting seat 2 for installing and fixing it. The mounting seat 2 includes a threaded sleeve 3 at its upper end, And the lubricating oil bottle 1 is threadedly connected with the threaded sleeve 3. When the lubricating oil in the lubricating oil bottle 1 is exhausted, it is convenient to replace; The air pin 6, the oil guide pin 5 are fixedly connected with the air intake pin 6, and the top surface of the groove 4 is provided with openings corresponding to the upper ends of the oil guide pin 5 and the air intake pin 6, and the oil guide pin 5 It is connected to the input end of the lubricating oil pump 7 fixedly installed on the lower side of the mounting base 2, and the air intake pin 6 is connected to the air intake cap 8 arranged outside the groove 4. The air intake cap 8 can ensure the internal and external ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com