Smart Initiator Based on Low Temperature Co-fired Ceramics

A low-temperature co-fired ceramic and detonator technology, which is used in weapon accessories, offensive equipment, fuzes, etc., to achieve the effects of facilitating mass production, improving practicability, and high integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Delibrium explosillance based on low-temperature co-burning ceramic flying film explosion sequence.

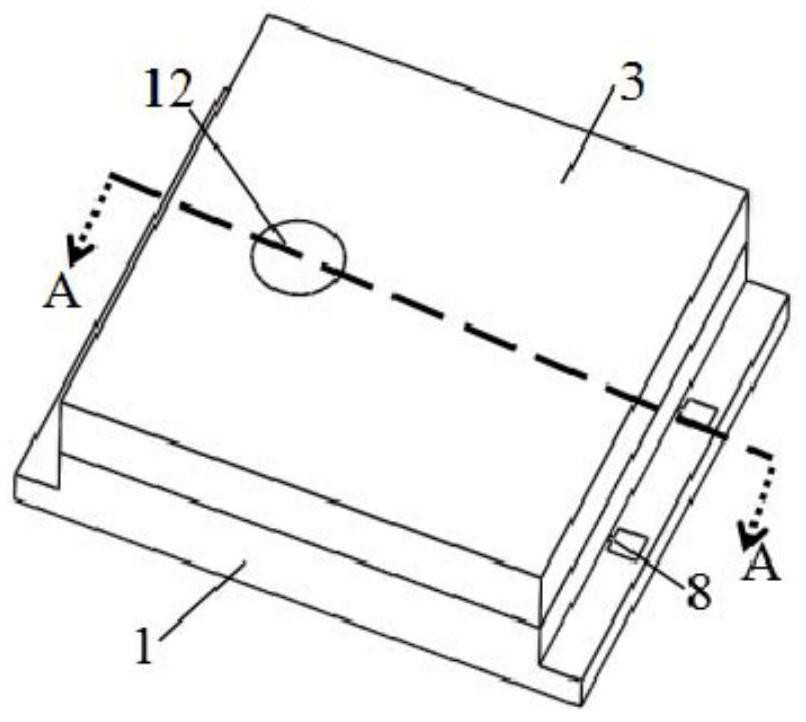

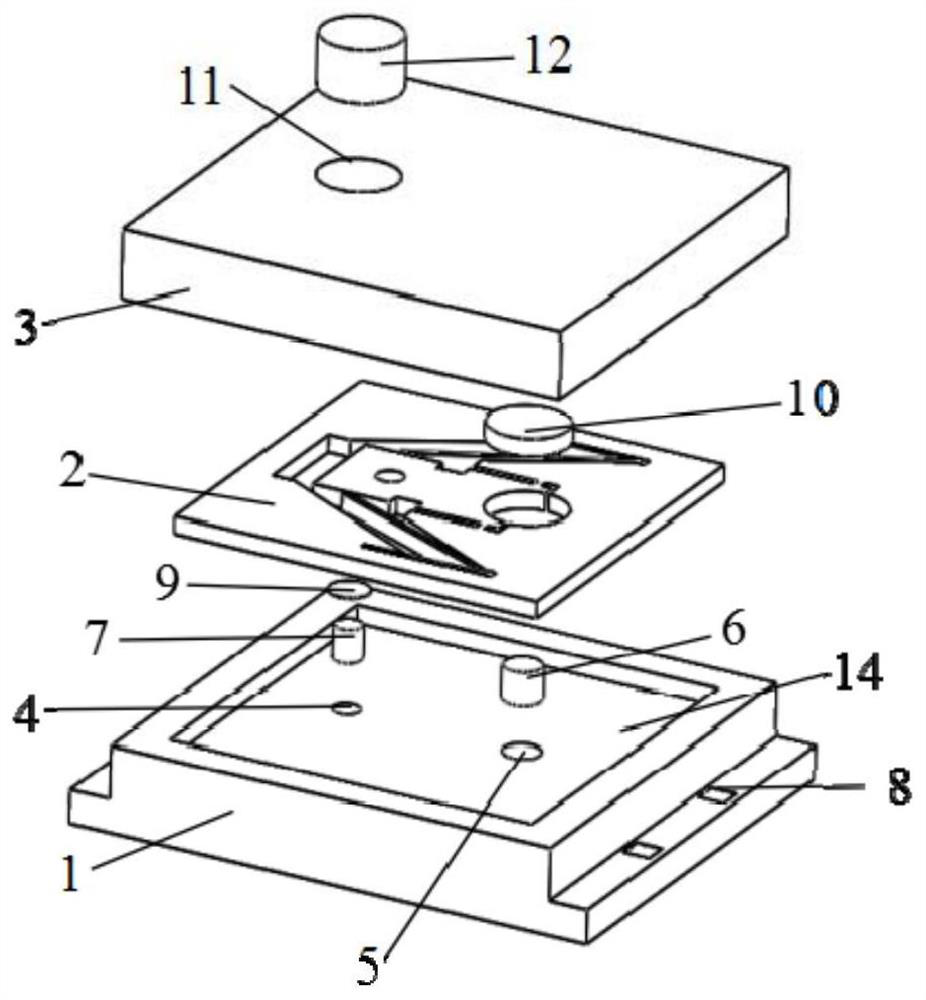

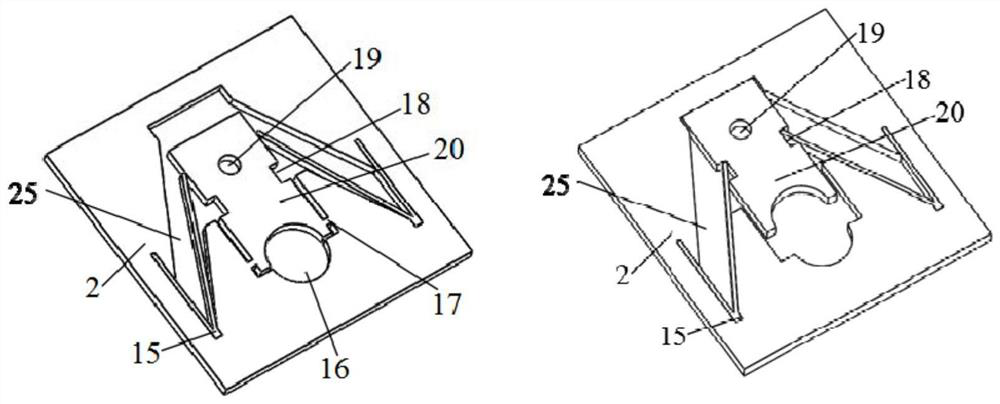

[0039] Combine figure 1 , figure 2 as well as Figure 6 The present invention is based on a smart kneador of a low-temperature co-burning ceramic flyer explosion sequence comprising: ceramic base 1, pyromems security layer substrate 2, ceramic output pharmaceutical layer substrate 3, an explosion pharmaceutical hole 4, ignition pharmaceutical hole 5, point The gunpowder column 6, the explosion plate 7, the pad 8, the flying film 9, the gas medicine column 10, the output pharmaceutical hole 11, the output pharmaceutical column 12 and the cavity 14; binding image 3 The pyromems security layer substrate 2 includes a gas generating aperture 16, a solid cantilever beam 17, a groove 18, an acceleration bore 19, an security slide 20, and a groove 25, which is used for the built-in elastic sheet 15. Combine Figure 4 , Figure 5 The ceramic base 1 includes a planar electrical resistan...

Embodiment 2

[0055] Smart Dynamic Based on the Explosion Sequence of Low Temperature Ceramics Explosion.

[0056] Combine figure 1 , Figure 6 as well as Figure 7 The present invention is based on a smart kneador of a low-temperature co-burning ceramic explosive explosion sequence comprising: a ceramic base 1, a pyromems security layer substrate 2, a ceramic outputting a pharmaceutical layer substrate 3, an explosion pharmaceutical aperture 4, an ignition pore 5, an ignition drug The column 6, the explosion-proof column 7, the pad 8, the proposal column 21, the boom post 22, the gas generator column 10, the output pharmaceutical hole 11, the output pharmaceutical column 12, and the cavity 14; binding Figure 8 The pyromems security layer substrate 2 includes a gas generating aperture 16, a solid cantilever beam 17, a groove 18, an explosionary pharmaceutical hole 23, an security slide 20, and a groove 25 for built-in elastic sheet 15. . Combine Figure 4 , Figure 9 The ceramic base 1 includes a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com