Light driven ultrasonic probe and ultrasonic imaging system thereof

An ultrasonic probe and light-driven technology, which is applied in the direction of using wave/particle radiation devices to transmit sensing components, can solve line crosstalk, difficulty in selecting ultrasonic transducers, and piezoelectric transducers that do not have high-frequency parts for receiving ultrasonic waves. Information capacity and other issues to achieve the effect of expanding the scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

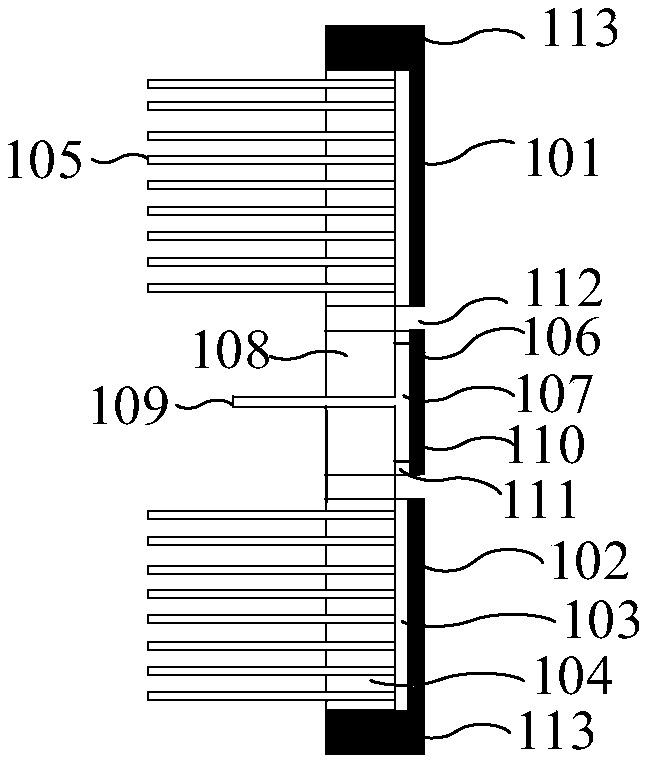

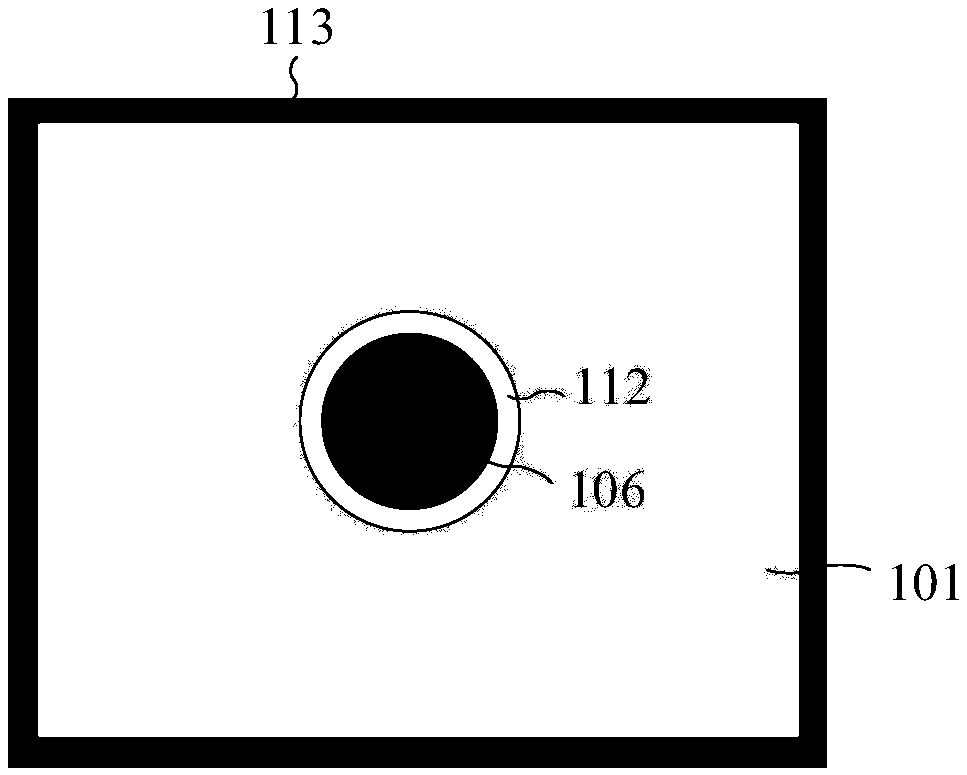

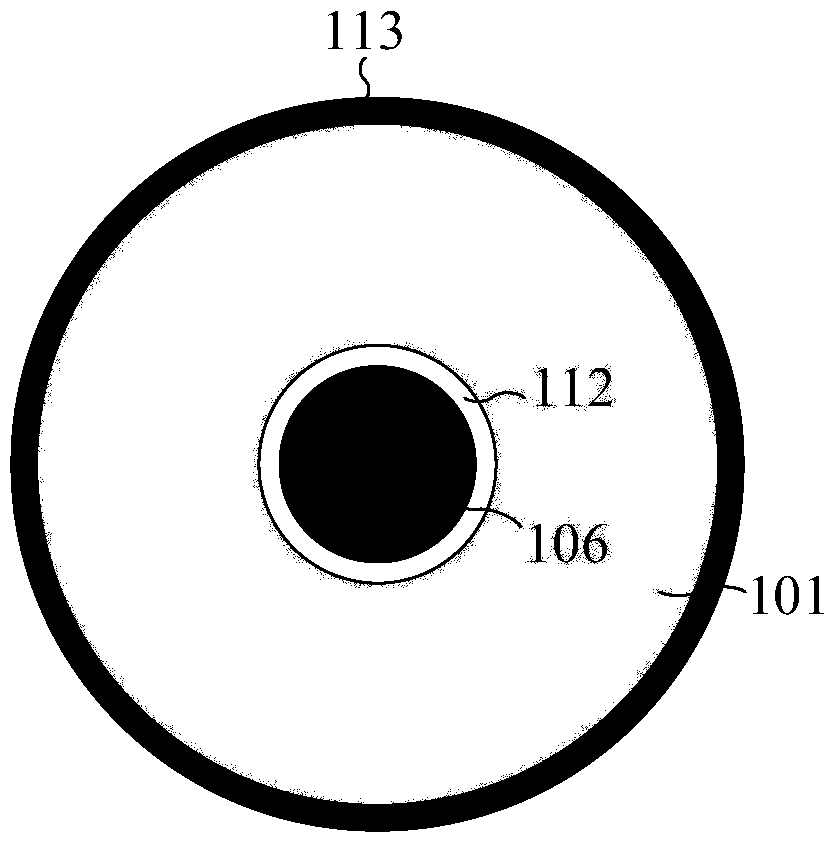

[0039] The light-driven ultrasound probe 204 of the present invention is composed of a photoacoustic emitter 101 for emitting ultrasound and a Fabry-Perot (F-P) cavity 106 for receiving ultrasound. A Fabry-Perot (F-P) cavity 106 is located in the center of the photoacoustic emitter 101 .

[0040] The upper surface of the Fabry-Perot (F-P) cavity 106 and the upper surface of the photoacoustic emitter 101 together constitute the front end of the light-driven ultrasonic probe 204 .

[0041] As shown in FIG. 1 , the ultrasonic transmitter 101 includes a photoacoustic conversion film 102 and a transparent substrate 103 . The photoacoustic conversion film 102 is coated on the upper surface of the transparent substrate 103 , and the lower surface of the transparent substrate 103 is welded to the front surface of the support base 104 made of glass. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com