Combined exhaust cooling system of laser cutting device

A cooling system and laser cutting technology, applied in auxiliary devices, embroidery machine mechanisms, embroidery machines, etc., can solve the problems of optical fiber performance attenuation, harm to the human respiratory system, and inability to discharge smoke outdoors, and achieve the effect of performance protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the present invention will be described in further detail in conjunction with the accompanying drawings and specific embodiments.

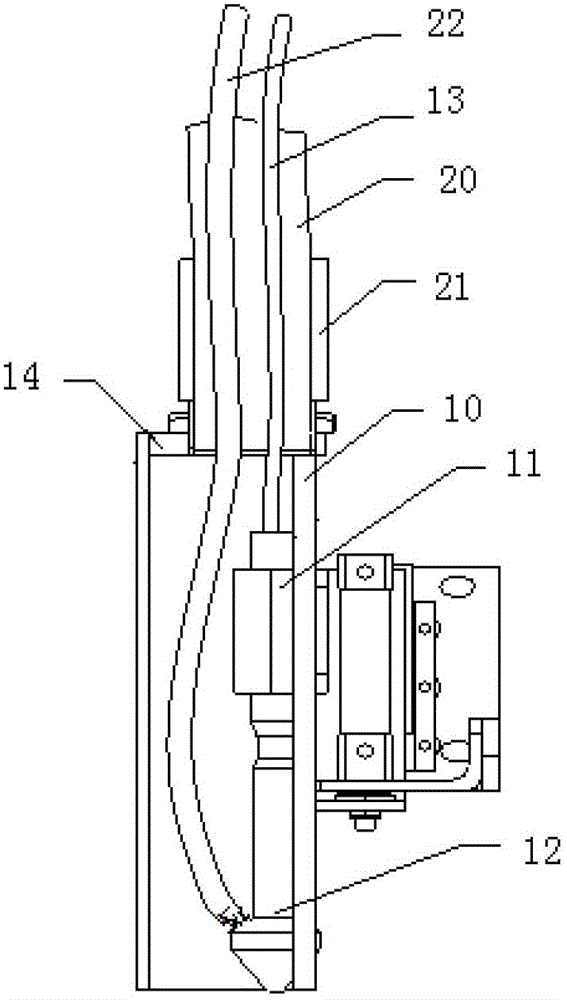

[0021] figure 1 It is a schematic diagram of the composite exhaust air cooling system of the laser cutting device of the present invention. As shown in the figure, the composite exhaust air cooling system of the laser cutting device includes: a laser cutter head 12 for cutting or embroidery, an optical fiber 13 for transmitting laser light, and a smoke exhaust pipe 10 that generates smoke when discharging cutting materials. The laser cutter head 12 is arranged on the In the smoke exhaust pipe 10, an air duct plug 21 is formed on the upper baffle plate 14 of the smoke exhaust pipe. One end of the air duct 20 is connected to the exhaust pipe 10 through the air duct plug 21, and the other end of the air duct 20 is connected to the air duct pipe. , thus, the laser cutter head is set to work in a closed space, and the smoke generated whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com