Device and method for measuring model flow-induced noise in working section of water tunnel

A technology of working section and internal model, which is applied in the direction of measuring device, measuring ultrasonic wave/sonic wave/infrasonic wave, and using electric device, etc., which can solve the problems of small measurement results and the problem of air boundary without considering the absolute soft pipe of acoustics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

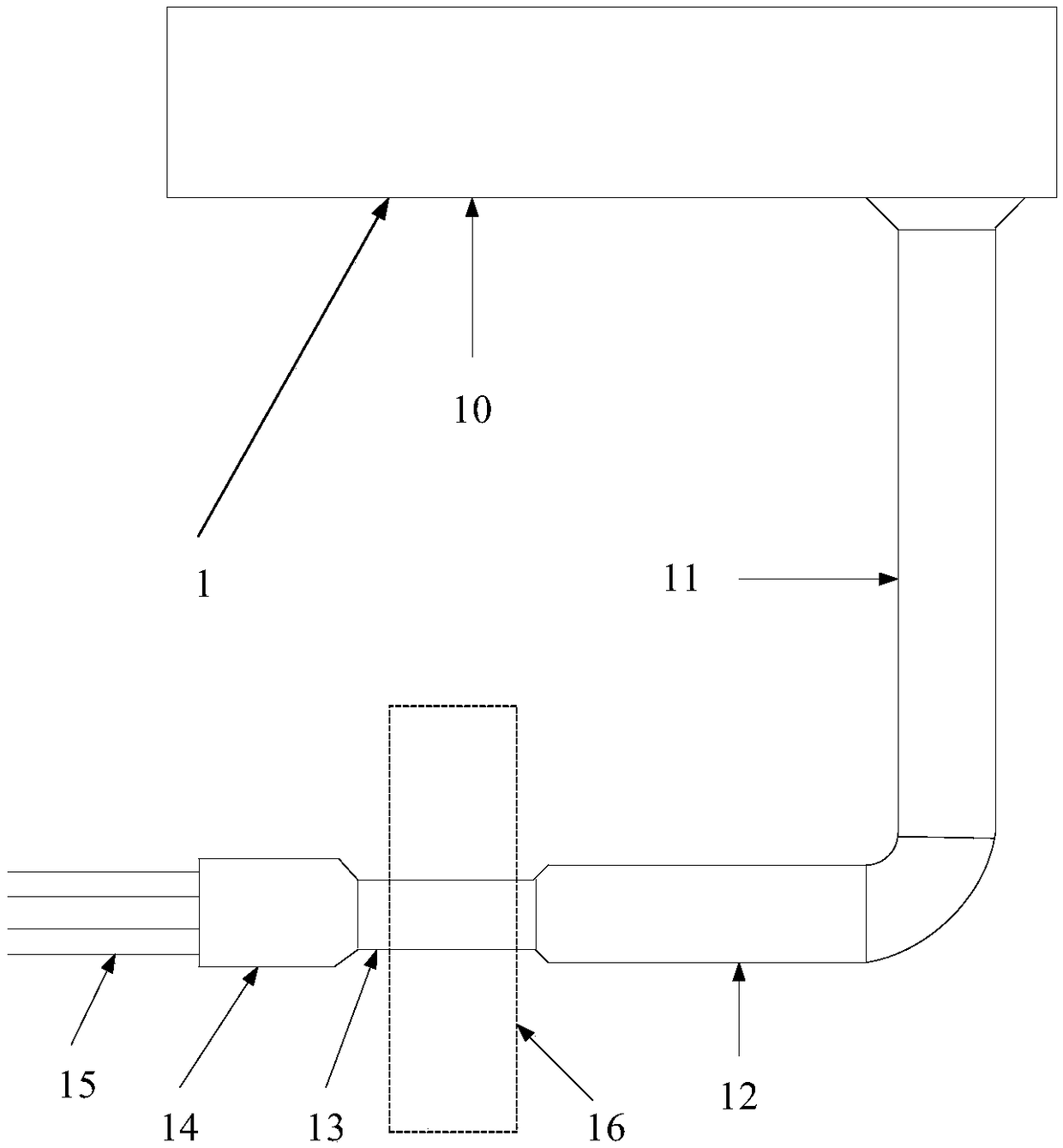

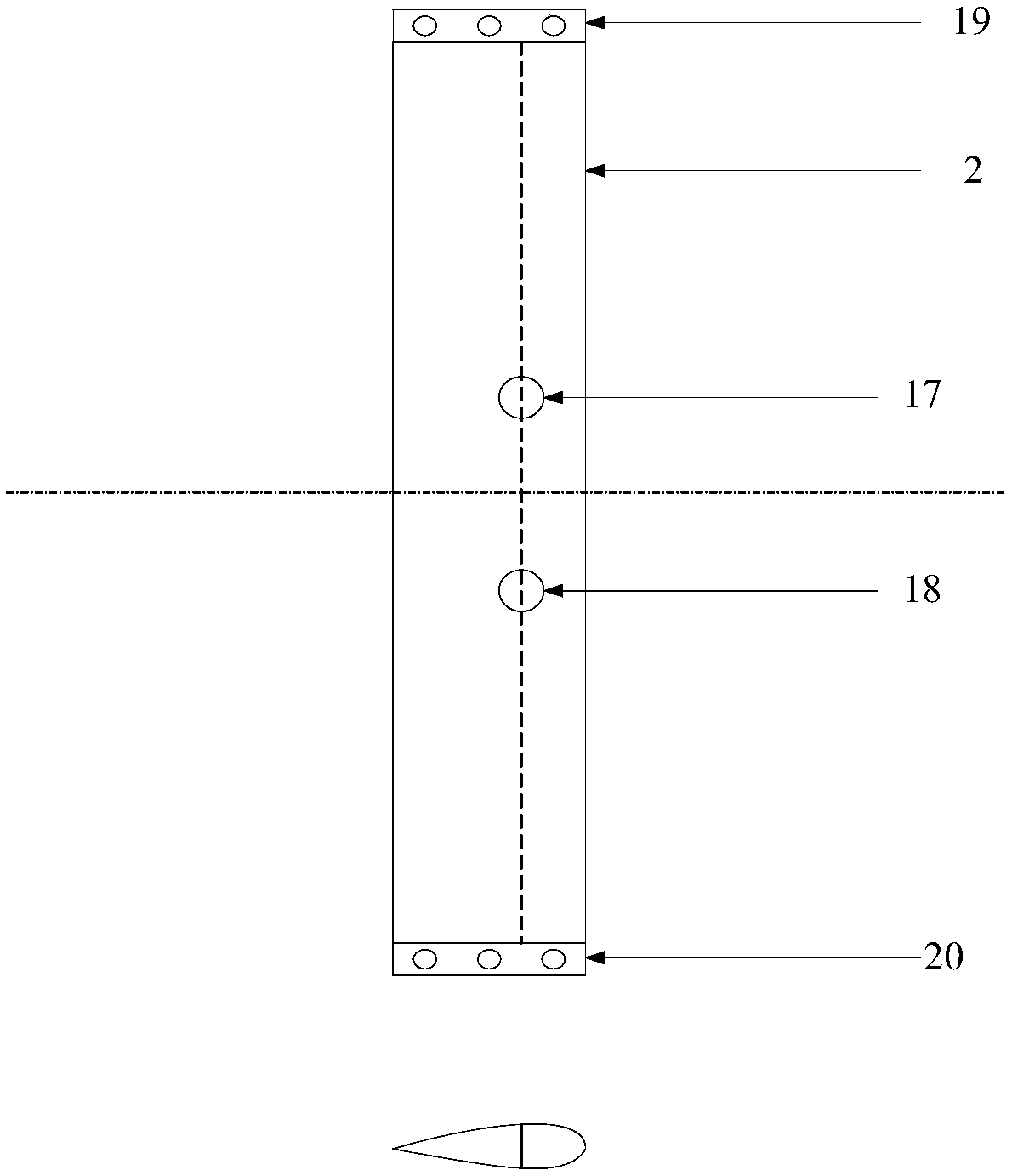

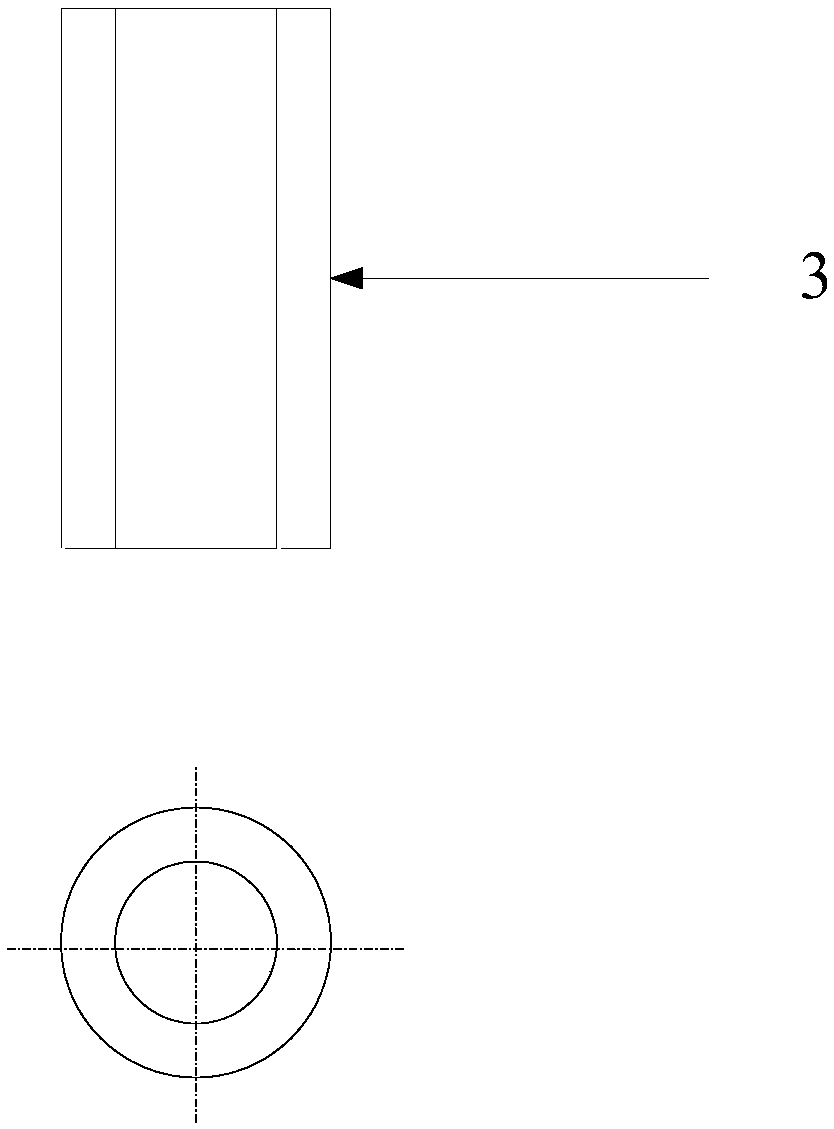

[0031] As shown in the figure, 1 is the gravity type low-noise water tunnel, 10 is the upper water tank, 11 is the vertical pipe, 12 is the contraction section, 13 is the working section, 14 is the diffusion section, 15 is the drain pipe, and 16 is the reverberation Box, 2 is the bracket, 17 is the upper through hole, 18 is the lower through hole, 19 is the upper fixed end, 20 is the lower fixed end, 3 is the vibration damping pad, 4 is the round cake-shaped air bag, 5 is the pulsation pressure sensor, 6 7 is a signal source, 8 is a power amplifier, and 9 is a spherical sound source.

[0032] A device for measuring model flow-induced noise in the working section of a water tunnel, characterized in that it includes a bracket 2, a vibration-damping pad 3, a circular cake-shaped air bag 4, a pulsation pressure sensor 5, and a hydrophone 6; the bracket is of a thin airfoil structure , the two ends of the support are installed on the pipe wall of the diffusion section of the water ...

specific Embodiment 2

[0041] A device for measuring flow-induced noise of a model in a working section of a water tunnel, comprising a gravity-type low-noise water tunnel 1, a bracket 2, a vibration-damping pad 3, a circular pie-shaped air bag 4, a pulsation pressure sensor 5, and a hydrophone 6;

[0042] The gravity type low-noise water tunnel 1 is composed of an upper water tank 10, a vertical pipe 11, a contraction section 12, a working section 13, a diffusion section 14, a drain pipe 15 and a reverberation box 16. The podium casing that is processed by the ratio is placed in the working section 13; firstly, the water pump is used to inject water into the upper water tank 1, and after reaching a certain water level, the valve of the vertical pipe 11 is opened, and the water is filled with the shrinking section 12. Section 13 and diffusion section 14, by arranging and combining the drain pipes 15 with different apertures, opening the valve controlling the drain pipe 15, the water will flow through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com