Light intensity detection circuit, light intensity detection method and device

A light intensity detection and circuit technology, which is applied in the direction of measuring devices, measuring circuits, photometry, etc., can solve the problems of sensitivity differences and poor uniformity of pixel units, and achieve the effect of eliminating sensitivity differences and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

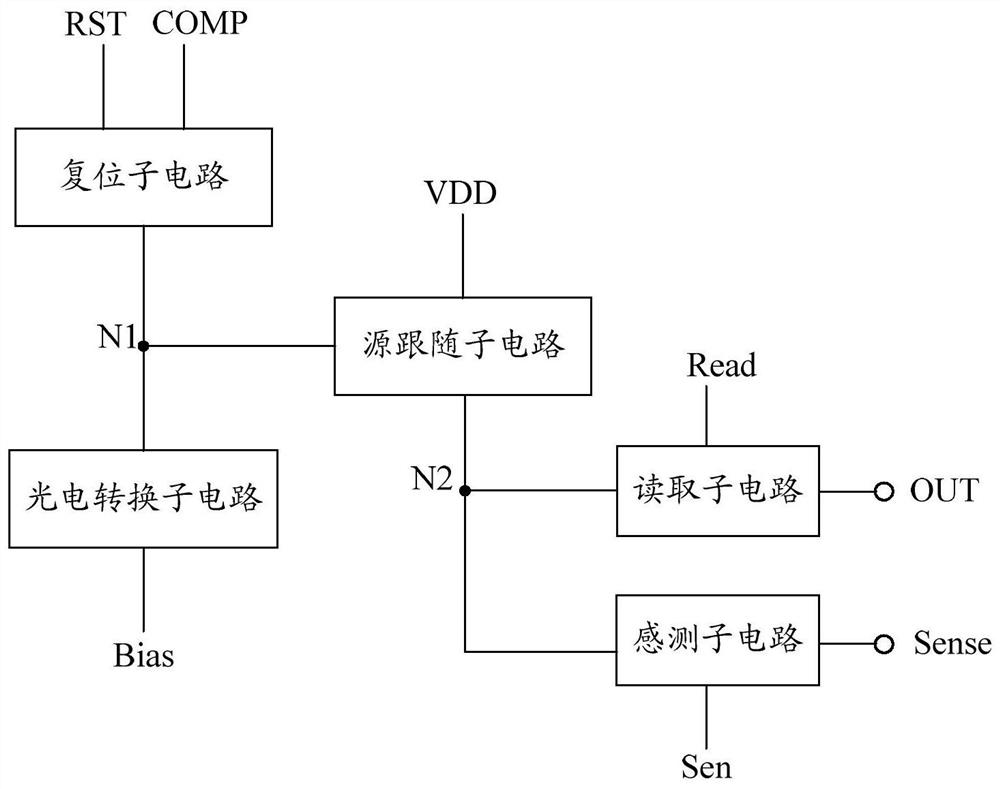

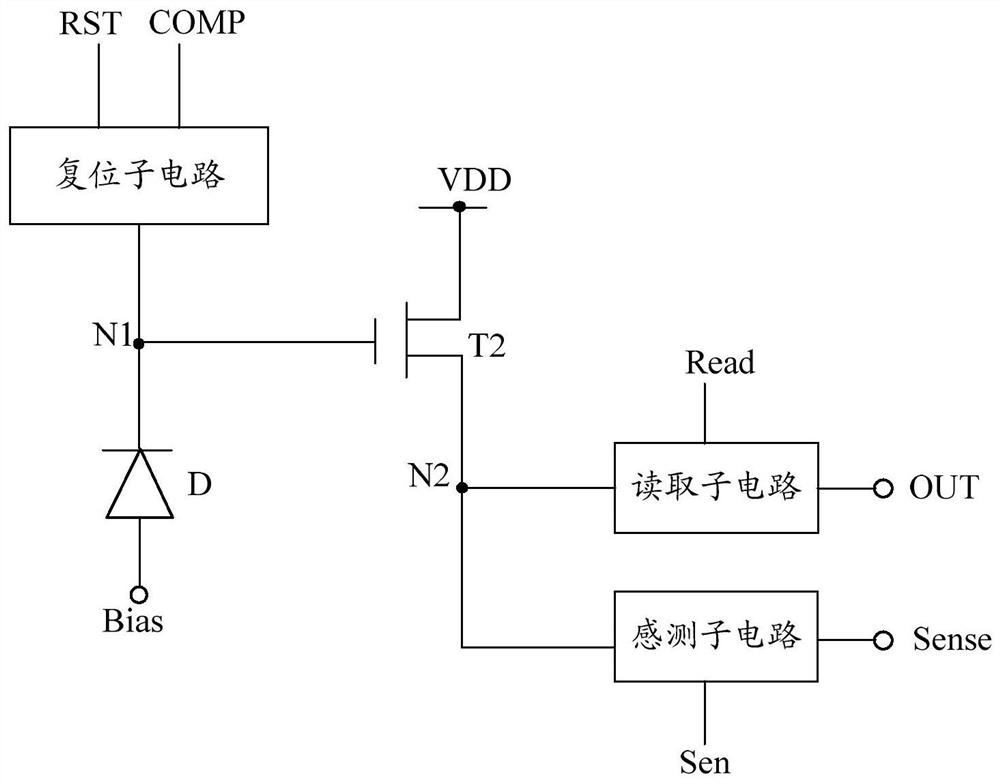

[0049] figure 1 It is a schematic structural diagram of the light intensity detection circuit of the first embodiment of the present application. like figure 1 As shown, the light intensity detection circuit of this embodiment includes: a photoelectric conversion sub-circuit, a source-following sub-circuit, a reset sub-circuit, a reading sub-circuit and a sensing sub-circuit.

[0050] Specifically, the photoelectric conversion sub-circuits are respectively connected to the bias voltage terminal Bias and the first node N1, and are used to generate corresponding electrical signals according to the incident light signal, and output them to the first node N1; the source follower sub-circuits are respectively connected to the first node N1 , the first voltage terminal VDD is connected to the second node N2, and is used to generate a corresponding voltage signal or current signal according to the electrical signal of the first node N1 and output it to the second node N2; the readin...

no. 2 example

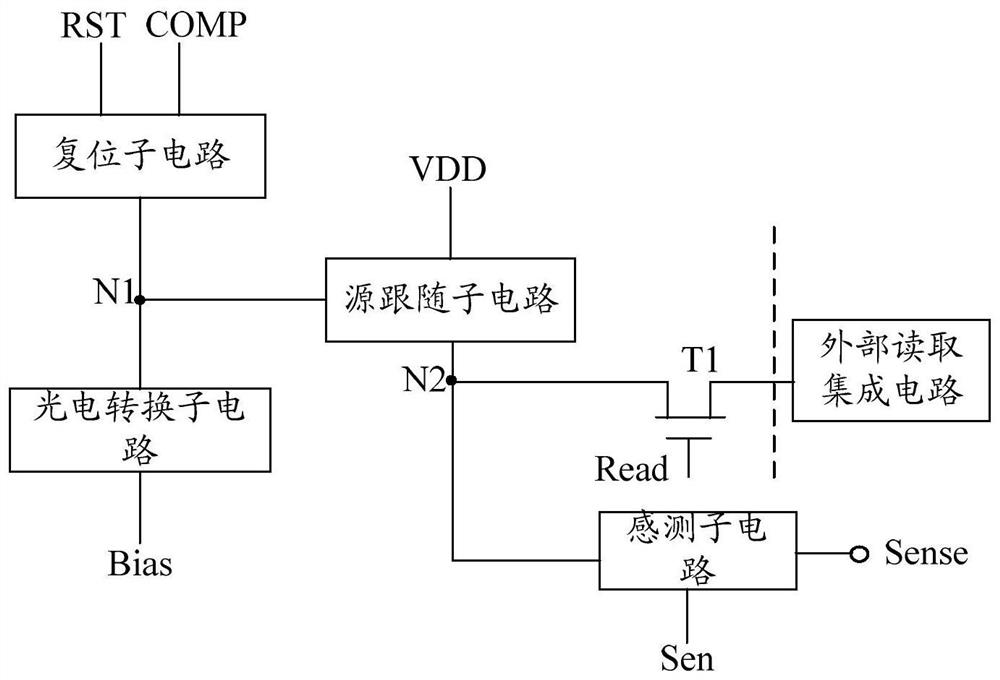

[0079] In this embodiment, the light intensity detection circuit further includes a multiplexing sub-circuit, and the multiplexing sub-circuit includes: a first transistor T1 inside the pixel unit and a multiplexer MUX outside the pixel unit. By using a multiplexer MUX, the number of transistors within a pixel cell is further reduced to maximize fill factor.

[0080] In an exemplary embodiment, Figure 9 The equivalent circuit diagram of the multiplexing sub-circuit provided for the embodiment of the present application, such as Figure 9 As shown, the multiplexing sub-circuit includes: a first transistor T1 located inside the pixel unit and a multiplexer MUX located outside the pixel unit, the sensing sub-circuit is an external sensing circuit located outside the pixel unit, and the reading The subcircuit is an external readout integrated circuit located outside the pixel unit.

[0081] Specifically, the control pole of the first transistor T1 is connected to the read contr...

no. 3 example

[0088] Based on the inventive concepts of the foregoing embodiments, the embodiments of the present application further provide a light intensity detection device, including the light intensity detection circuit described in any one of the foregoing embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com