Large-size dry hot rock in-situ fracturing test device

A dry-hot rock, large-scale technology, used in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as low loading pressure, large volume of true triaxial simulation, and inability to achieve high-temperature loading. , to achieve the effect of large loading surface, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

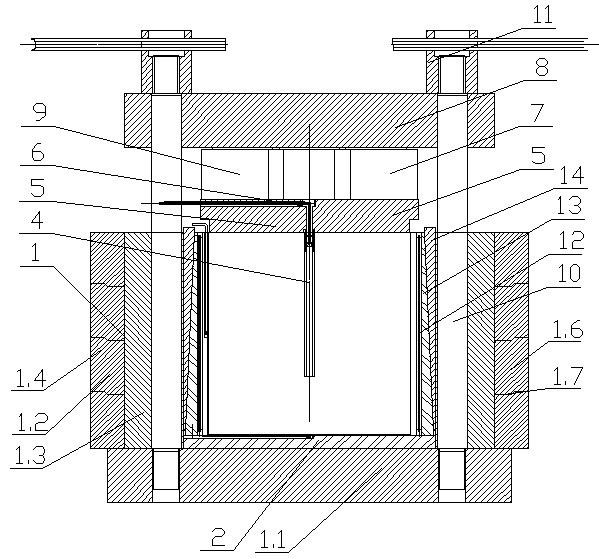

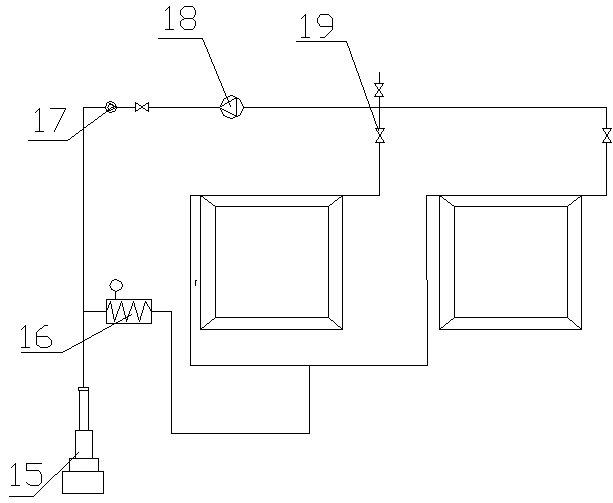

[0029] Such as figure 1 , 2 As shown, the present invention includes a square fracturing box 1 for placing rocks 3, the bottom of the fracturing box 1 is provided with a lower fixing plate 2, the rock 3 is placed on the lower fixing plate 2, and an injection well is pre-buried in the center of the rock 3 4. An upper fixing plate 5 is arranged above the rock 3, and a pipeline 6 for connecting the injection well 4 is arranged inside the upper fixing plate 5. A hydraulic loading cylinder 7 is installed on the upper fixing plate 5, and an upper loading cylinder 7 is arranged above the hydraulic loading cylinder 7. Support base 8, a plurality of hydraulic loading cylinders 9 that push upper fixing plate 5 to press down rock 3 are provided between upper bearing 8 and upper fixing plate 5, and hydraulic loading cylinders 9 are installed on upper fixing plate 5.

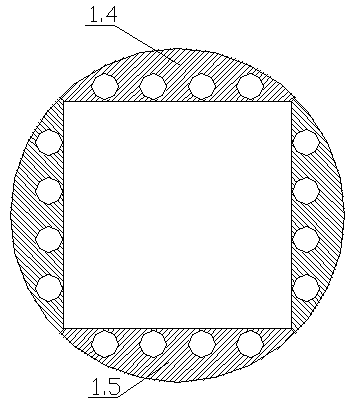

[0030] The fracturing box 1 includes a lower support base 1.1, and a pressure bearing plate 1.2 is arranged around the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com